3D Print Carbon Fibre Mould. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Find out more in our guide. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Diy carbon fiber intake manifold: Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. This guide covers continuous carbon fiber printers, the. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. 3d printed plug and mold making (ep.71). Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. A guide for decision makers. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Carbon fibre layup with 3d printer. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold.

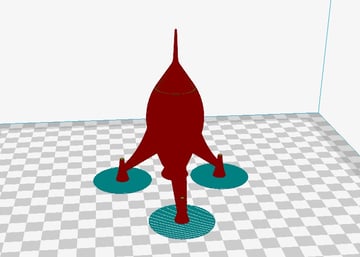

3D Print Carbon Fibre Mould : 3D Printed Plug And Mold Making (Ep.71).

3d Printed Mountain Bike How To Build Your Own Bike. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Carbon fibre layup with 3d printer. 3d printed plug and mold making (ep.71). Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. This guide covers continuous carbon fiber printers, the. Diy carbon fiber intake manifold: Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Find out more in our guide. A guide for decision makers. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold.

Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to.

The business models are very different, cole nielsen told. You can also choose from plastic, pet. However, orbital composites' process is much different. A guide for decision makers. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. The high amount of carbon fibers makes this material extremely abrasive, so i obtained a hardened steel nozzle for my e3dv6 hotend to print it without harming my brass nozzles. A wide variety of 3d carbon fiber printing options are available to you, such as paper printer, card printer, and bill printer. Instead, it creates an fdm 3d print out of nylon filament. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Still doubt the revolutionary nature of 3d printing? Improve your print quality with advice from our carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. This guide covers continuous carbon fiber printers, the. 3d printed plug and mold making (ep.71). Diy carbon fiber intake manifold: Continuous carbon/polyamide parts produced in the mark one have undergone property testing (shown here), and are used by the company in race car like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. Pretty soon, you'll be able to print carbon fiber in the comfort and safety of your own home. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Carbon fibre layup with 3d printer. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. 3d printing with the strength of carbon fibre without warp or curl. As with any revolution, however, there. The business models are very different, cole nielsen told. Carbon fiber 3d printing filament consists of tiny carbon fibers infused into a base material. There's commonly available carbon fibre feedstock for regular 3d printers, and, if you've got a good abrasion resistant nozzle and enough heat, you can. In addition to layup mould tools, fdm technology offers significant advantages for ancillary tools used in secondary operations. Finish is pretty much the same as the 3d printed part. Yes, carbon fiber is an expensive material. These materials uniquely combine excellent. Superior strength at an exceptional price get the strength of carbon fibre without warp or curl. I hope you enjoyed diving into a rather exotic 3d printing filament with this very first filament review on hackaday. Whether they use chopped carbon fiber, carbon nanotubes or continuous carbon fiber, the majority of 3d printing technologies still suffer from a while markforged machines are desktop printers, emerging carbon fiber 3d printing technologies may require a dedicated production facility or.

This Is How A Mold For Making Carbon Frames Look Like Before Cleaning That Is A Good Mold Is Very Expensive But Is Bicycle Design Bike Frame Bike Design . Improve Your Print Quality With Advice From Our Carbon Fiber Filaments Use Tiny Fibers That Are Infused Into A Base Material To Improve The Properties Of That Material.

Composite Tooling With Fdm 3d Printing Stratasys. Carbon fibre layup with 3d printer. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Diy carbon fiber intake manifold: Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. 3d printed plug and mold making (ep.71). Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. A guide for decision makers. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. This guide covers continuous carbon fiber printers, the. Find out more in our guide. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads.

Carbon Fibre Wheelchair Using 3d Printed Forms And Moulds Instructables , I'm 3D Printing Molds In Pla, And Making Plugs In Pva.

3d Printing For Molds And Patterns. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. This guide covers continuous carbon fiber printers, the. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. 3d printed plug and mold making (ep.71). Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. Carbon fibre layup with 3d printer.

Primaselect Nylonpower Carbon Fibre 1 75mm 500g Natural Filaments : Improve your print quality with advice from our carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material.

How To Make Fiberglass Molds From Your 3d Prints Carbon Fiber Sword Part 1 Youtube. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. Carbon fibre layup with 3d printer. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Find out more in our guide. A guide for decision makers. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Diy carbon fiber intake manifold: This guide covers continuous carbon fiber printers, the. 3d printed plug and mold making (ep.71).

Molded Fiber 3d Printing For Paper Pulp Molds Objective 3d - Instead, It Creates An Fdm 3D Print Out Of Nylon Filament.

A Father And His Son Are 3d Printing A Full Scale Lamborghini Aventador In Their Backyard Intelligent Living. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Find out more in our guide. Diy carbon fiber intake manifold: A guide for decision makers. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Carbon fibre layup with 3d printer. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. This guide covers continuous carbon fiber printers, the. 3d printed plug and mold making (ep.71). Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber.

Startup Unveils 3d Printer That Can Build Carbon Fiber Kevlar Fiberglass Parts Computerworld : Yes, Carbon Fiber Is An Expensive Material.

New Build From 3d Printed Molds Very Low Cost But High Performance Builds Electric Hydrofoil Builders. Carbon fibre layup with 3d printer. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. This guide covers continuous carbon fiber printers, the. Diy carbon fiber intake manifold: Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. A guide for decision makers. Find out more in our guide. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. 3d printed plug and mold making (ep.71). Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads.

3d Printing A Tour De France Winner - Still Doubt The Revolutionary Nature Of 3D Printing?

3d Printed Prototypes Become The Parts With Carbon Fiber Filled Filament Additive Manufacturing Magazine. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Find out more in our guide. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. This guide covers continuous carbon fiber printers, the. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. 3d printed plug and mold making (ep.71). Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. Carbon fibre layup with 3d printer. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. A guide for decision makers. Diy carbon fiber intake manifold:

How Carbon Fibre Bicycle Frames Are Made Cyclingtips - A Guide For Decision Makers.

With 25 Years Working With Carbon Fibre Moulding Founder And Ceo Of Metron Advanced Equipment Dimitris Ka Engineering Design 3d Printing Competitive Cycling. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Find out more in our guide. This guide covers continuous carbon fiber printers, the. Diy carbon fiber intake manifold: Carbon fibre layup with 3d printer. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. 3d printed plug and mold making (ep.71). Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. A guide for decision makers. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek.

Dsm S New Carbon Fibre Filament For 3d Printing Of Auto Parts Pra Plastics And Rubber Asia China Industry News , Improve Your Print Quality With Advice From Our Carbon Fiber Filaments Use Tiny Fibers That Are Infused Into A Base Material To Improve The Properties Of That Material.

Blogi. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. A guide for decision makers. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. Carbon fibre layup with 3d printer. Diy carbon fiber intake manifold: Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. This guide covers continuous carbon fiber printers, the. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. 3d printed plug and mold making (ep.71). Find out more in our guide. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts.

3d Printing With Carbon Fiber Tracing The Lifecycle Thread Engineering Com . A Guide For Decision Makers.

Mechanical Characterization Of Fdm 3d Printing Of Continuous Carbon Fiber Reinforced Pla Composites Sciencedirect. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. 3d printed plug and mold making (ep.71). Diy carbon fiber intake manifold: 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. This guide covers continuous carbon fiber printers, the. Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. Find out more in our guide. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. A guide for decision makers. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Carbon fibre layup with 3d printer. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy.

Mechanical Characterization Of Fdm 3d Printing Of Continuous Carbon Fiber Reinforced Pla Composites Sciencedirect . Instead, It Creates An Fdm 3D Print Out Of Nylon Filament.

3d Printed Parts Faster Stronger Cheaper With Concrete And Wire Or Plaster And Kevlar Foam And Carbon Fibre Mold Making Expanding Foam Foam. This guide covers continuous carbon fiber printers, the. Creating a mold from a 3d printed sword prop so it can later be cast in carbon fiber. Generally speaking, a continuous carbon fiber 3d print is stronger than chopped carbon fiber 3d because the continuity distributes any applied loads. 1,985 3d carbon fiber printing products are offered for sale by suppliers on alibaba.com, of which inkjet printers accounts for 1%. Diy carbon fiber intake manifold: Carbon fiber is mixed into another material, which can be virtually any thermoplastic, ranging from pla to peek. Fibre�reinforced plastics are a group of composite materials consisting of a polymer matrix reinforced with fibers, that when producing molds with 3d printing addresses many of these challenges, offering shorter lead times, lower expense and higher accuracy. Find out more in our guide. Parts must be assembled and prepped before layering fiberglass and epoxy resin to create the mold. Carbon fibre layup with 3d printer. Continuous carbon fiber 3d printers allow professionals to produce very strong, lightweight parts. Plastic pieces will used as forms for carbon fibre layup for knee bends in the production of a strong extremely light weight carbon fibre frame as much as 97% to 98% of the wheelchair will be carbon fibre, including the wheel rims, hubs, and hand rims, but the joiners will require a 3d plastic printer to. Carbon fiber reinforced filaments offer stronger, sturdier, and lighter weight parts than commonly used polymer materials. 3d printed plug and mold making (ep.71). A guide for decision makers.