3D Print Infill Not Connecting. . i assume you were referring to the outline overlap parameter in simplify3d? I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. That can cause some structural problems in some pieces. My print looks bad infill looks messy and incomplete gaps between infill and outer wall However, now that i'm trying some bigger prints and i'm running into infill material excess. The zigzag pattern simply creates the very pattern as it's named. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. Outline overlap = percentage of extrusion width that will overlap with. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang.

3D Print Infill Not Connecting : However, Now That I'm Trying Some Bigger Prints And I'm Running Into Infill Material Excess.

Awesome Demonstration Of Different Infill Percentages 3dprinting. . i assume you were referring to the outline overlap parameter in simplify3d? That can cause some structural problems in some pieces. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. However, now that i'm trying some bigger prints and i'm running into infill material excess. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The zigzag pattern simply creates the very pattern as it's named. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. My print looks bad infill looks messy and incomplete gaps between infill and outer wall Outline overlap = percentage of extrusion width that will overlap with. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects.

Lowering it under 10% is a certain failure while.

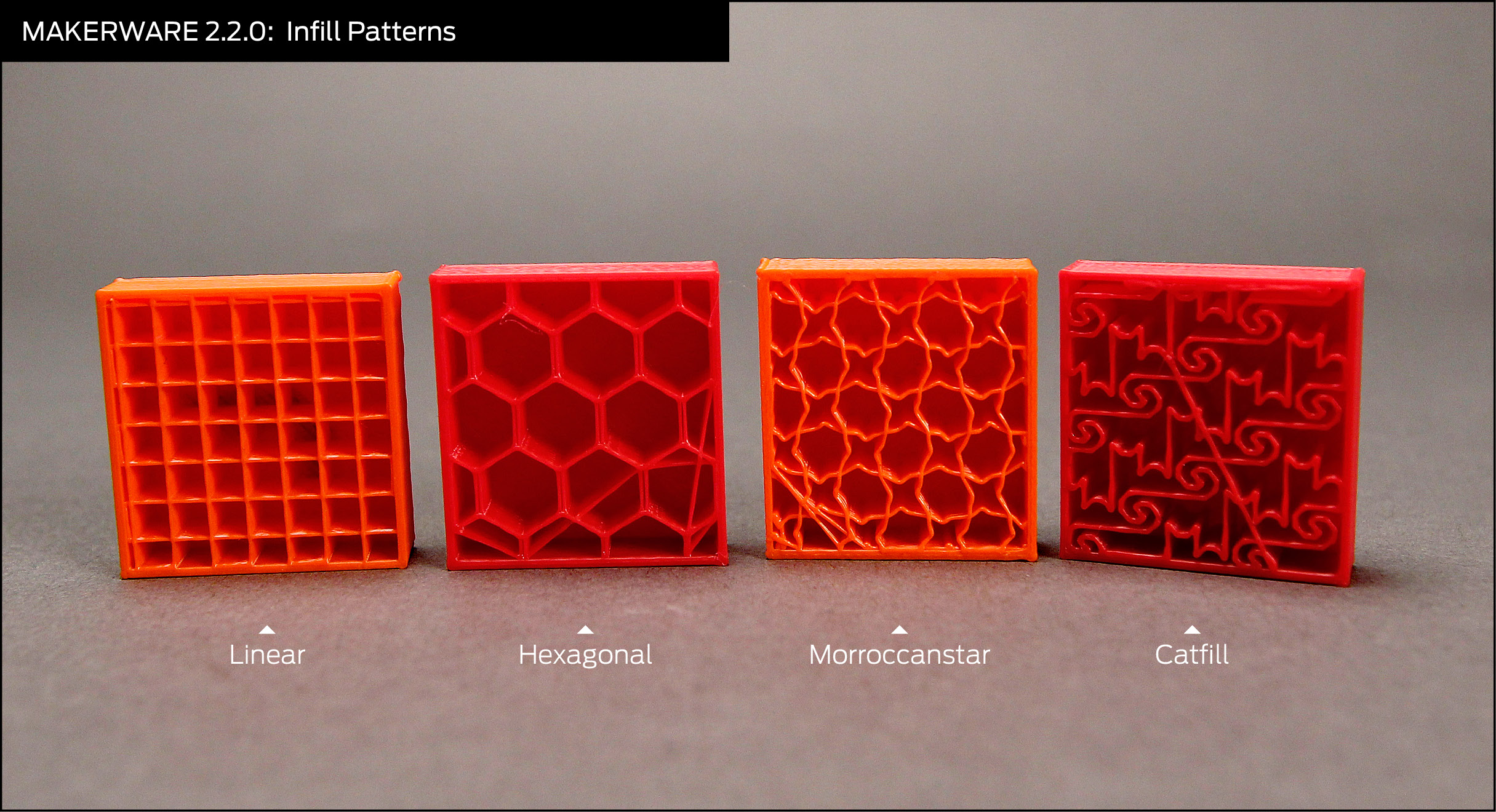

Stefan from cnc kitchen on youtube is showing off some really cool experimentation in this video that take advantage of easy to use physical simulation software to create infills for your 3d. Quality is not the focus of this study but the relationship between quality and layer height is generally accepted3. Basically the final 3d printed model will have different infill densities depending on the region of the model. But what are the differences, and. Edit the infill ratio of your prints. All users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). Lowering it under 10% is a certain failure while. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. Quality relates to the general aspect of printed parts based on their layer height2. So remove that concept from your mind. The steps of the extruder are not 100% configured, as i could not because of these faults. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. However, now that i'm trying some bigger prints and i'm running into infill material excess. Outline overlap = percentage of extrusion width that will overlap with. This way the outside of the print would have the look. I can't even print pla infill at 200 mm/s. Amongst the ten standard types. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. For those unfamiliar, shells are the outer layers of a print which make the walls of an object, prior to the various infill levels being printed within. There seem to be a never ending supply of inventive ways that home experimenters are forwarding 3d printing. Since this inconsistency also appears with the infill in 100% in some parts of the piece. Typically, the extrusion multiplier or flow setting in your slicing software is too high (see the section above). Besides the actual printing process, infill will affect the strength or feel of the final product. Did you just get a new silhouette alta® 3d printer? It's very similar to the lines pattern but the difference is, lines are connected in one long line, resulting in less flow. 3d printing provides you with an incredible creation and prototyping power. . i assume you were referring to the outline overlap parameter in simplify3d? 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The final setting of the infill ratio often depends on the experience of a person preparing the files for printing. Infill percentage in 3d printing. No matter the type of 3d printer you are using.

Common Problems In 3d Printing How To Resolve Them Part I Manufactur3d , The 3D Printing Troubleshooting Process Here Is Quite Easy.

Perimeter And Infill Not Touching Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. Outline overlap = percentage of extrusion width that will overlap with. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. However, now that i'm trying some bigger prints and i'm running into infill material excess. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. That can cause some structural problems in some pieces. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. The zigzag pattern simply creates the very pattern as it's named. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. My print looks bad infill looks messy and incomplete gaps between infill and outer wall . i assume you were referring to the outline overlap parameter in simplify3d?

3d Printing Infill The Basics Simply Explained All3dp , For Those Unfamiliar, Shells Are The Outer Layers Of A Print Which Make The Walls Of An Object, Prior To The Various Infill Levels Being Printed Within.

Gradient Infill For 3d Prints Cnc Kitchen. . i assume you were referring to the outline overlap parameter in simplify3d? Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. That can cause some structural problems in some pieces. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. However, now that i'm trying some bigger prints and i'm running into infill material excess. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. My print looks bad infill looks messy and incomplete gaps between infill and outer wall Outline overlap = percentage of extrusion width that will overlap with. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill.

Print Quality Guide : All users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill).

Prints Pillowing 3d Printer Stringing And Layers Splitting 3 Worst. . i assume you were referring to the outline overlap parameter in simplify3d? The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. My print looks bad infill looks messy and incomplete gaps between infill and outer wall Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. The zigzag pattern simply creates the very pattern as it's named. Outline overlap = percentage of extrusion width that will overlap with. That can cause some structural problems in some pieces. However, now that i'm trying some bigger prints and i'm running into infill material excess. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your.

3d Printing Infill And Density Visual 3d Printing Diy 3d Printer Designs 3d Printer Kit - What's The 3D Printing Problem?

3d Printed Samples With Different Infill Patterns A Linear B Download Scientific Diagram. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. That can cause some structural problems in some pieces. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Outline overlap = percentage of extrusion width that will overlap with. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. However, now that i'm trying some bigger prints and i'm running into infill material excess. The zigzag pattern simply creates the very pattern as it's named. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. . i assume you were referring to the outline overlap parameter in simplify3d? Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. My print looks bad infill looks messy and incomplete gaps between infill and outer wall

3d Printing Tips On How To Improve 3d Print Quality All3dp . But What Are The Differences, And.

Perimeter And Infill Not Touching Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts. That can cause some structural problems in some pieces. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. . i assume you were referring to the outline overlap parameter in simplify3d? My print looks bad infill looks messy and incomplete gaps between infill and outer wall Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. However, now that i'm trying some bigger prints and i'm running into infill material excess. The zigzag pattern simply creates the very pattern as it's named. Outline overlap = percentage of extrusion width that will overlap with.

Infill Not Connecting No Category Talk Manufacturing 3d Hubs , Typically, The Extrusion Multiplier Or Flow Setting In Your Slicing Software Is Too High (See The Section Above).

Choosing Infill Percentage For 3d Printed Parts 3dpros. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. Outline overlap = percentage of extrusion width that will overlap with. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. My print looks bad infill looks messy and incomplete gaps between infill and outer wall . i assume you were referring to the outline overlap parameter in simplify3d? The zigzag pattern simply creates the very pattern as it's named. However, now that i'm trying some bigger prints and i'm running into infill material excess. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. That can cause some structural problems in some pieces. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

First Layer And Infill Issues Hardware Firmware And Software Help Prusa3d Forum : There Are No Registration Marks In 3D Printing, And That Means 3D Printers Have No Specific Data To If This Does Happen, Increasing The Infill Overlap Setting Allows The Infill And The Shell To Connect As.

Spotty Infill Issue Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts. . i assume you were referring to the outline overlap parameter in simplify3d? The zigzag pattern simply creates the very pattern as it's named. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Outline overlap = percentage of extrusion width that will overlap with. However, now that i'm trying some bigger prints and i'm running into infill material excess. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. That can cause some structural problems in some pieces. My print looks bad infill looks messy and incomplete gaps between infill and outer wall This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line.

3d Printing A 3d Honeycomb Infill Concept Engineerdog - This Way The Outside Of The Print Would Have The Look.

Infill Failure When Printing Larger Prints 3d Printing Stack Exchange. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The zigzag pattern simply creates the very pattern as it's named. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. However, now that i'm trying some bigger prints and i'm running into infill material excess. Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. My print looks bad infill looks messy and incomplete gaps between infill and outer wall That can cause some structural problems in some pieces. . i assume you were referring to the outline overlap parameter in simplify3d? The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Outline overlap = percentage of extrusion width that will overlap with.

Spotty Infill Issue Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts , Best Infill For Strength Vs Material Used.

Infill Lines Connection Problem Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. My print looks bad infill looks messy and incomplete gaps between infill and outer wall . i assume you were referring to the outline overlap parameter in simplify3d? Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. Outline overlap = percentage of extrusion width that will overlap with. However, now that i'm trying some bigger prints and i'm running into infill material excess. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. The zigzag pattern simply creates the very pattern as it's named. That can cause some structural problems in some pieces. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

Why Does My Printer Under Extrude Ideato3d . Sometimes Parts Were Gotten Stronger With Minimal Infill But Good Wall Thickness Than Parts With.

3d Print Infill Patterns Explained The 3d Bros. The problem can be described as that the infill lines do not attach to the walls at the printing starting point of the line. That can cause some structural problems in some pieces. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. My print looks bad infill looks messy and incomplete gaps between infill and outer wall Connect infill lines = connect the ends where the infill pattern meets the inner wall using a line which follows the shape of the inner wall. Outline overlap = percentage of extrusion width that will overlap with. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. . i assume you were referring to the outline overlap parameter in simplify3d? However, now that i'm trying some bigger prints and i'm running into infill material excess. This video is about a common problem with the infill (as well on the wall but usually not noticeable) on fdm 3d printed objects. The zigzag pattern simply creates the very pattern as it's named. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper surfaces that will be printed on top of the infill. I'm new to 3d printing an i just got a creality ender 3 and i think i'm getting some good results with small prints. Version 2.0.0+ win64 operating system type + version win 10 pro 1903 3d printer brand / version + firmware version (if known) mk3 3.7.2 behavior bridge infill is wrongly calculated for infill = 0% and do not hang.