3D Print Layer Height. Depending on your extruder, it can also damage the filament preventing it to. That said, for larger prints, you really won't want to lower the layer height too much. In the worth cas the plastic can expand/react/change state inside the hotend. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. Today we'll find out which layer height you should choose to get the strongest prints! Layer height is exactly what it sounds like: I printed test specimens with layer heights. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. 3d printing layer height and its effect on part strenght and print speed. Used properly, this setting will increase your print's.

3D Print Layer Height . Layer Height Is Basically Equivalent To Vertical Resolution In 3D Printed Objects.

Effects Of Layer Height On Sla Dlp Lcd 3d Print. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Used properly, this setting will increase your print's. Depending on your extruder, it can also damage the filament preventing it to. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Layer height is exactly what it sounds like: The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. In the worth cas the plastic can expand/react/change state inside the hotend. Today we'll find out which layer height you should choose to get the strongest prints! Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. That said, for larger prints, you really won't want to lower the layer height too much. 3d printing layer height and its effect on part strenght and print speed. I printed test specimens with layer heights.

Is the height of layers on top of each other that are measured in the thickness of mm.

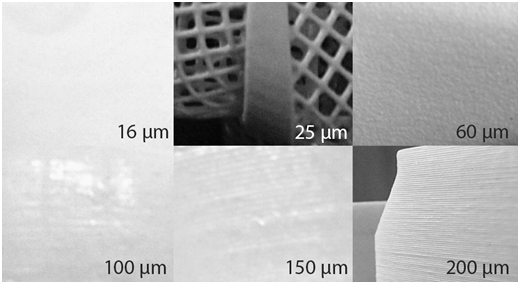

Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Layer thickness not only affects the speed (printing time), but aslo the quality of each print. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. Today we'll find out which layer height you should choose to get the strongest prints! That said, for larger prints, you really won't want to lower the layer height too much. So why would i use a 0.8mm or thicker nozzle? At larger layer heights, print lines start to look like toothpaste. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. Narrower extrusion widths increase the number of perimeters that must be printed to produce a specific wall thickness. Layer height in 3d printing doesn't substantially affect part strength. A printer with a.6mm nozzle can go up to.4mm layer heights, and a part with.1mm layer heights will take twice as long as one at.2mm, so these factors are. If you have all the time in the world (and a reliable machine), you have the option to 3d print with the finest resolution and take your chances that your speed settings are correct. The surface of the underside being supported in the reason for this is the layer lines in the 3d print. 3d printing layer height and its effect on part strenght and print speed. As the name implies, layer height is the exact height of each cured layer. Is there one, or could a 1mm nozzle print at.08 layer heights? Layer height is exactly what it sounds like: The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. The term 3d printing can refer to a variety of processes in which. Is the height of layers on top of each other that are measured in the thickness of mm. I printed test specimens with layer heights. The thinner the layer height (or layer thickness) the finer the detail of the print on the z axis (the vertical dimension of your print), but the more here's a diagram to better illustrate layer height 3d printing. I have not heard of a minimum height based on your nozzle diameter. The first layer height determines the thickness of the first layer that is printed on the bed. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. These layer lines act as weak points, so less force is required along the layer lines to create. The take away here is that layer height has a significant effect on the resolution of organic (curvy) parts. Although this generally works fine in most cases, you'll see a big drop in print quality and consistency with bigger nozzles and layer height. Layer height is less important in this orientation as most curves and angles will be printed in the x and y axis. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines.

Pla 3d Printing Settings Tips Pla Material Profile Sd3d Printing : For The Test Print, We Set The First Layer Height To 100%.

Technologies Free Full Text Paste Extruder Hardware Add On For Desktop 3d Printers Html. Depending on your extruder, it can also damage the filament preventing it to. That said, for larger prints, you really won't want to lower the layer height too much. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Layer height is exactly what it sounds like: In the worth cas the plastic can expand/react/change state inside the hotend. 3d printing layer height and its effect on part strenght and print speed. Used properly, this setting will increase your print's. Today we'll find out which layer height you should choose to get the strongest prints! Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. I printed test specimens with layer heights. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way.

3d Printing Layer Height Under The Microscope 3d Printer Chat - That Said, For Larger Prints, You Really Won't Want To Lower The Layer Height Too Much.

3d Printing Layer Height How Much Does It Matter All3dp. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Depending on your extruder, it can also damage the filament preventing it to. Today we'll find out which layer height you should choose to get the strongest prints! 3d printing layer height and its effect on part strenght and print speed. Layer height is exactly what it sounds like: That said, for larger prints, you really won't want to lower the layer height too much. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. I printed test specimens with layer heights. Used properly, this setting will increase your print's. In the worth cas the plastic can expand/react/change state inside the hotend.

3d Printing Layer Height How Much Does It Matter All3dp - Layer height is basically equivalent to vertical resolution in 3d printed objects.

Effects Of Layer Height On Sla Dlp Lcd 3d Print. Used properly, this setting will increase your print's. Layer height is exactly what it sounds like: This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. 3d printing layer height and its effect on part strenght and print speed. In the worth cas the plastic can expand/react/change state inside the hotend. Depending on your extruder, it can also damage the filament preventing it to. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. Today we'll find out which layer height you should choose to get the strongest prints! I printed test specimens with layer heights. That said, for larger prints, you really won't want to lower the layer height too much.

3d Printer In Los Altos Aleana Yiu Makexyz Com : While Your Here Also Check Out Our Preview Of The Printsyst Beta Web Slicer!

3d Printing The Perfect First Layer 3dmaker Engineering. In the worth cas the plastic can expand/react/change state inside the hotend. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Used properly, this setting will increase your print's. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. That said, for larger prints, you really won't want to lower the layer height too much. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. I printed test specimens with layer heights. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Layer height is exactly what it sounds like: Today we'll find out which layer height you should choose to get the strongest prints! Depending on your extruder, it can also damage the filament preventing it to. 3d printing layer height and its effect on part strenght and print speed.

3d Printing Layer Height How Much Does It Matter All3dp , Lowering The First Layer Height And Keeping The Width At 100% Will Result In Better Adhesion With Small, Tight, Almost Seamless Lines.

Creat3d Handy 3d Printing Tips What Do Microns Really Mean. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. That said, for larger prints, you really won't want to lower the layer height too much. 3d printing layer height and its effect on part strenght and print speed. In the worth cas the plastic can expand/react/change state inside the hotend. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Today we'll find out which layer height you should choose to get the strongest prints! Layer height is exactly what it sounds like: Depending on your extruder, it can also damage the filament preventing it to. I printed test specimens with layer heights. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Used properly, this setting will increase your print's.

Custom 3d Printing With Pla , This Selection Of Layer Heights Gives You The Ideal Balance Of Speed And Resolution.

Creat3d Handy 3d Printing Tips What Do Microns Really Mean. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Depending on your extruder, it can also damage the filament preventing it to. Used properly, this setting will increase your print's. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. In the worth cas the plastic can expand/react/change state inside the hotend. 3d printing layer height and its effect on part strenght and print speed. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Today we'll find out which layer height you should choose to get the strongest prints! Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Layer height is exactly what it sounds like: That said, for larger prints, you really won't want to lower the layer height too much. I printed test specimens with layer heights.

Blog Rp Space - What Is The Best Layer Thickness For Your Print?

3d Printing First Layer Problems How To Make It Perfect All3dp. Today we'll find out which layer height you should choose to get the strongest prints! 3d printing layer height and its effect on part strenght and print speed. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. In the worth cas the plastic can expand/react/change state inside the hotend. Layer height is exactly what it sounds like: Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. I printed test specimens with layer heights. Depending on your extruder, it can also damage the filament preventing it to. Used properly, this setting will increase your print's. That said, for larger prints, you really won't want to lower the layer height too much. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer.

Layer Height Archives Shropshire 3d Blog : Also Known As Layer Thickness Or Layer Height, The Vertical Resolution Was The First Major Numerical Differentiation Between Early 3D Printers.

What Knowledge Is Necessary To Use A 3d Printer Caddesignhelp Com. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. 3d printing layer height and its effect on part strenght and print speed. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. I printed test specimens with layer heights. Layer height is exactly what it sounds like: In the worth cas the plastic can expand/react/change state inside the hotend. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Today we'll find out which layer height you should choose to get the strongest prints! That said, for larger prints, you really won't want to lower the layer height too much. Used properly, this setting will increase your print's. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Depending on your extruder, it can also damage the filament preventing it to. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer.

Layer Height And Print Times Enabling The Future . Layer Thickness Not Only Affects The Speed (Printing Time), But Aslo The Quality Of Each Print.

High Precision 3d Printer Head 3d Printer Extruder Head. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Today we'll find out which layer height you should choose to get the strongest prints! I printed test specimens with layer heights. 3d printing layer height and its effect on part strenght and print speed. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. Used properly, this setting will increase your print's. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. In the worth cas the plastic can expand/react/change state inside the hotend. Depending on your extruder, it can also damage the filament preventing it to. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. That said, for larger prints, you really won't want to lower the layer height too much. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Layer height is exactly what it sounds like:

What Is The Smallest Layer Height Possible On A Commercial 3d Printer Quora : That's About The Diameter Of The Extruded Plastic That Emerges From Your Extruder, And, Theoretically,.4 Mm Is The Highest Layer Height You Can Print With This Nozzle.

Creat3d Handy 3d Printing Tips What Do Microns Really Mean. Today we'll find out which layer height you should choose to get the strongest prints! On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Layer height is exactly what it sounds like: Depending on your extruder, it can also damage the filament preventing it to. That said, for larger prints, you really won't want to lower the layer height too much. In the worth cas the plastic can expand/react/change state inside the hotend. Used properly, this setting will increase your print's. The exact height of each layer of plastic extruded, cured, or sintered by a 3d printer. This setting is adjusted through a slicer program and has many more effects on the final print than one might think at first. Typically, the quality difference you see in a print that's note that lowering your layer height increases the number of layers in your object, so it'll take longer to print and have more opportunities to fail along the way. 3d printing layer height and its effect on part strenght and print speed. I printed test specimens with layer heights. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness.