3D Printed Prosthetics Fda. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Fda registered medical device facility. 3d printed prosthetics can greatly benefit children. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Finger prosthetics, microtechnology in its pure state. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. This makes 3d printed prosthetics for children a perfect solution. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. Leg prosthesis, the most complex of all. 3d printed prosthetics literally grow with you. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). The unnoticeable prosthesis, unlimited tomorrow. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all.

3D Printed Prosthetics Fda . 3D Printed Prosthetic Hand Via Thingverse.

Fda Releases Medical Device 3d Printing Guidelines Idata Research. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. 3d printed prosthetics can greatly benefit children. This makes 3d printed prosthetics for children a perfect solution. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The unnoticeable prosthesis, unlimited tomorrow. 3d printed prosthetics literally grow with you. Finger prosthetics, microtechnology in its pure state. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Leg prosthesis, the most complex of all. Fda registered medical device facility. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all.

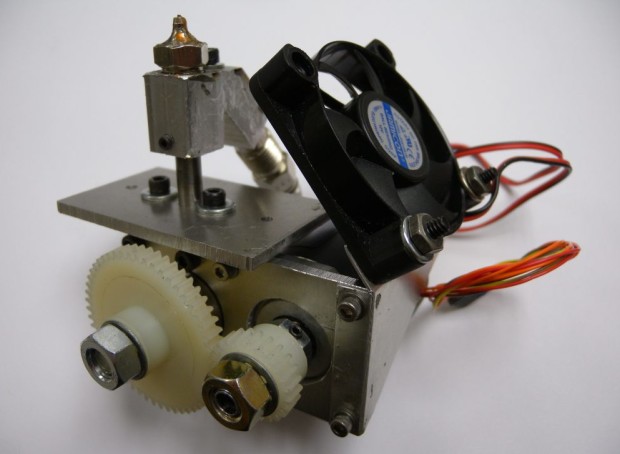

It allows designers and engineers to create complex parts for cars, machines or airplanes much cheaper and in much less time than any other production method.

The food and drug administration has approved the first prescription drug made through 3d printing: While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. See more ideas about prosthetics, prosthetic leg, 3d printing projects. This includes aesthetic factors such as skin tone. Leg prosthesis, the most complex of all. Whilst not the biggest deal ever, it is worth noting that these homemade 3d printed prosthetics are not regulated, and exist outside official ruling. Diy assistive devices that can be printed by virtually anyone, anywhere. Noted as well was the issue of reimbursement, which has some interest and needs more metrics. he said that, at the fda, we've tried to interact a. 3d printed prosthetic hand via thingverse. This puts prosthetics within financial reach of people who could not afford it otherwise, notably children due to the need to replace their prosthetics, more often than for adults, as they grow. The unnoticeable prosthesis, unlimited tomorrow. Doctors are hoping that 3d printing could help the 30 million people worldwide in need of prosthetic limbs and braces. Since the system uses affordable and accessible equipment, the plan is to release the software freely, so even small clinics can offer better and faster prosthetics and orthotics. In fact, you will be amazed even if you do not wear a prosthetic limb. It allows designers and engineers to create complex parts for cars, machines or airplanes much cheaper and in much less time than any other production method. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. They are utilising bioink to print develop live devices out of printer. A dissolvable tablet that treats seizures. Prosthetics can involve a lot of work and expertise to produce and fit and the who says there is currently a shortage of 40,000 trained prosthetists in poorer countries. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. The remote location of communities meant that exporting materials was all prosthetics can be customized to suit the user. The food and drug administration has approved the first prescription drug made through 3d printing: Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Consumer 3d printing is leading to an even bigger revolution: Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Tom gildea, a physician at the cleveland clinic. This post discusses where the technology is today and where it's heading. The printer uses a kind of layering process, by which one layer is added after the other until you have a fully formed object. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and quality.

Ortho . While Prosthetic Devices Have Continued To Advance Throughout History, 3D Printing Technology Has Emerged As A Revolutionary Way To Enhance This Medical Device By Avoiding The Traditional Negative Impacts That Are Often Associated With Modern Prosthetics.

Fda Drilling Down On Promise And Problems Of 3d Printing Ge News. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Finger prosthetics, microtechnology in its pure state. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. 3d printed prosthetics can greatly benefit children. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. 3d printed prosthetics literally grow with you. The unnoticeable prosthesis, unlimited tomorrow. Fda registered medical device facility. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Leg prosthesis, the most complex of all. This makes 3d printed prosthetics for children a perfect solution. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months.

Unyq Launches 3d Printed Prosthetic Leg Socket To Provide Total Leg Solution For Amputees 3d Printing Industry - Moreover, Prosthetics Need To Be Custom Fit To The Individual, Requiring A Production Time On The Order Of Weeks Or Months.

How 3d Printed Prosthetics Can Change The Lives Of Millions Of Amputees 3dsourced. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Leg prosthesis, the most complex of all. 3d printed prosthetics can greatly benefit children. 3d printed prosthetics literally grow with you.

Fda Clears 3d Systems D2p Software For Anatomical Models 3d Printing Media Network The Pulse Of The Am Industry : 3d printed prosthetics can greatly benefit children.

Fda Plans Meeting To Explore Regulation Medical Uses Of 3d Printing Technology Raps. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. 3d printed prosthetics can greatly benefit children. 3d printed prosthetics literally grow with you. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Finger prosthetics, microtechnology in its pure state. Fda registered medical device facility. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Leg prosthesis, the most complex of all. The unnoticeable prosthesis, unlimited tomorrow. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. This makes 3d printed prosthetics for children a perfect solution.

Let The Regulation Begin Fda Issues Guidance For 3d Printed Medical Devices Legacy Medsearch Medical Device Recruiters : They Are Utilising Bioink To Print Develop Live Devices Out Of Printer.

The Future Of 3d Printed Pills Innovation Smithsonian Magazine. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. This makes 3d printed prosthetics for children a perfect solution. Leg prosthesis, the most complex of all. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Finger prosthetics, microtechnology in its pure state. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. 3d printed prosthetics can greatly benefit children. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Fda registered medical device facility. The unnoticeable prosthesis, unlimited tomorrow. 3d printed prosthetics literally grow with you. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm).

Patient Specific Implants Design Printing With Fda Approval Psi , 3D Printing Is A Relatively New But Promising Technology Available To Professional Prosthetists And Amateurs Alike.

Beyond Prototyping The Promises And Problems Of 3d Printing Medical Product Outsourcing. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetics literally grow with you. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. Leg prosthesis, the most complex of all. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Finger prosthetics, microtechnology in its pure state. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. 3d printed prosthetics can greatly benefit children. The unnoticeable prosthesis, unlimited tomorrow. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. This makes 3d printed prosthetics for children a perfect solution. Fda registered medical device facility.

3d Printing In Healthcare Where Are We In 2019 Amfg : He Mentioned Prosthetics, Dental Applications, And Anatomical Models As Other Aspects Where The Fda Has Noticed A Great Deal Of Attention In 3D Printing.

How 3d Printed Prosthetics Can Change The Lives Of Millions Of Amputees 3dsourced. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. The unnoticeable prosthesis, unlimited tomorrow. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Fda registered medical device facility. Leg prosthesis, the most complex of all. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetics literally grow with you. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). 3d printed prosthetics can greatly benefit children. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Finger prosthetics, microtechnology in its pure state. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. This makes 3d printed prosthetics for children a perfect solution.

English Archivi Page 15 Of 56 Open Biomedical Initiative We Help - See More Ideas About Prosthetics, Prosthetic Leg, 3D Printing Projects.

First 3d Printed Ti Implant For The Sacroiliac Joint Gets Fda Clearance Orthofeed. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Finger prosthetics, microtechnology in its pure state. Fda registered medical device facility. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. 3d printed prosthetics can greatly benefit children. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). 3d printed prosthetics literally grow with you. The unnoticeable prosthesis, unlimited tomorrow. This makes 3d printed prosthetics for children a perfect solution. Leg prosthesis, the most complex of all. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with.

The Role Of 3d Printing In The Design And Manufacture Of Prosthetic Devices , Medical Devices Produced By 3D Printing Include Orthopedic And Cranial Implants, Surgical Instruments, Dental Restorations Such As Crowns, And External Prosthetics.

First 3d Printed Drug Approved By Fda. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Leg prosthesis, the most complex of all. 3d printed prosthetics can greatly benefit children. 3d printed prosthetics literally grow with you. Finger prosthetics, microtechnology in its pure state. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. The unnoticeable prosthesis, unlimited tomorrow. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Fda registered medical device facility. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. This makes 3d printed prosthetics for children a perfect solution. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm).

3d Printed Medical Devices The Process And The Fda S Stance - Medical Devices Produced By 3D Printing Include Orthopedic And Cranial Implants, Surgical Instruments, Dental Restorations Such As Crowns, And External Prosthetics.

Formlabs To 3d Print 3 000 Ventilator Adapters A Day With Fda Approval 3d Printing Media Network The Pulse Of The Am Industry. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. The unnoticeable prosthesis, unlimited tomorrow. This makes 3d printed prosthetics for children a perfect solution. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Leg prosthesis, the most complex of all. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Finger prosthetics, microtechnology in its pure state. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Fda registered medical device facility. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. 3d printed prosthetics literally grow with you. 3d printed prosthetics can greatly benefit children.

First 3d Printed Ti Implant For The Sacroiliac Joint Gets Fda Clearance Orthofeed - This Puts Prosthetics Within Financial Reach Of People Who Could Not Afford It Otherwise, Notably Children Due To The Need To Replace Their Prosthetics, More Often Than For Adults, As They Grow.

Fda Seeks To Pave Regulatory Pathway That Keeps Pace With Advances In Plasticstoday Com. 3d printed (left to right, top) models of a brain, blood vessel, surgical guide, and (bottom) medallion printed on fda 3d printers. The unnoticeable prosthesis, unlimited tomorrow. Like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Medical devices produced by 3d printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. 3d printed prosthetics can greatly benefit children. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that the fda approved a 3d printed polyetherketoneketone (pekk) skull implant, which was successfully implanted by oxford performance materials (opm). Leg prosthesis, the most complex of all. 3d printed prosthetics literally grow with you. Finger prosthetics, microtechnology in its pure state. Fda registered medical device facility. This makes 3d printed prosthetics for children a perfect solution. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Protosthetics is the first central fab facility in the united states to be based solely on 3d printing and cad/cam manufacturing. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months.