3D Printer Extrusion Calculation. With this process, we designed these experimental projects that. The 3d printer is a great invention. The result of poor extrusion calibration. Dual extrusion is the process of 3d printing with multiple filaments. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters I think this might have to do with the filament acting like a spring inside the bowden. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. 3d printer direct drive extruder assembly for fdm 3d printers. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. It only takes a minute to sign up. Download files and build them with your 3d printer, laser cutter, or cnc. Thingiverse is a universe of things. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time.

3D Printer Extrusion Calculation , The Above Illustration Is Sourced From Desktop Metal (Bound Metal Deposition™.

3d Printer Extruder Calibration Steps Per Mm 3daddict. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters Thingiverse is a universe of things. Dual extrusion is the process of 3d printing with multiple filaments. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. The 3d printer is a great invention. With this process, we designed these experimental projects that. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. It only takes a minute to sign up. 3d printer direct drive extruder assembly for fdm 3d printers. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. Download files and build them with your 3d printer, laser cutter, or cnc. The result of poor extrusion calibration. I think this might have to do with the filament acting like a spring inside the bowden.

Alibaba.com offers 903 dual extrusion 3d printer products.

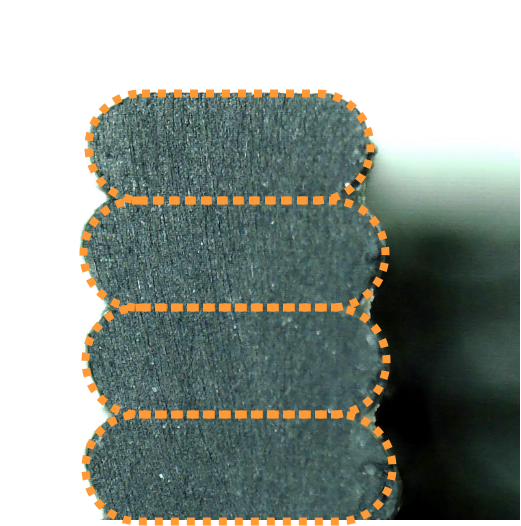

The result of poor extrusion calibration. It only takes a minute to sign up. Explaining the close relationship between nozzle. Thingiverse is a universe of things. Here's our mini guide on 3d printer nozzle height; Alibaba.com offers 903 dual extrusion 3d printer products. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. Read the compatibility guide first before pledging. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. In my search for a printer a i stumbled upon the term reprap. Make sure to edit configuration.scad for your belt type, extrusion type, extrusion mounting screw, pulley type, bushing type, idler bearing type, and extrusion lengths (it will calculate rod lengths based off this). Moved printer configuration to printer_conf.scad. I allows the user to print (almost)anything he/she could imagine! About 5% of these are digital printers. With this process, we designed these experimental projects that. The above illustration is sourced from desktop metal (bound metal deposition™. Though most updated slicers should handle standard extrusion width vs nozzle diameter for you automatically. Download files and build them with your 3d printer, laser cutter, or cnc. Extrusion consists of heating the material (filament) and pushing it through a nozzle. The result of poor extrusion calibration. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. 3d printer direct drive extruder assembly for fdm 3d printers. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. Dual extrusion is the process of 3d printing with multiple filaments. The 3d printer is a great invention. I think this might have to do with the filament acting like a spring inside the bowden. 'replicating rapid prototyper' in other words, a printer that could prints its self. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters Different printers print rigid.ink best at different settings, so don't be afraid to experiment.

3d Printing Using Concrete Extrusion A Roadmap For Research Sciencedirect - 'fLow Rate' Is A Slicer Setting That Tells The 3D Printer How Much Plastic To Extrude.

Flow Rate Matters 3dprinting. 3d printer direct drive extruder assembly for fdm 3d printers. With this process, we designed these experimental projects that. Dual extrusion is the process of 3d printing with multiple filaments. The 3d printer is a great invention. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. Thingiverse is a universe of things. It only takes a minute to sign up. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. I think this might have to do with the filament acting like a spring inside the bowden. Download files and build them with your 3d printer, laser cutter, or cnc. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The result of poor extrusion calibration. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner - Extrusion Consists Of Heating The Material (Filament) And Pushing It Through A Nozzle.

Pdf Development Of Plastic Filament Extruder For 3d Printing. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. The result of poor extrusion calibration. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. Dual extrusion is the process of 3d printing with multiple filaments. With this process, we designed these experimental projects that. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters It only takes a minute to sign up. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. The 3d printer is a great invention. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude.

Eqowm2uxzppe0m , 3d printer direct drive extruder assembly for fdm 3d printers.

Pdf Analyzing The Effect Of Nozzle Diameter In Fused Deposition Modeling For Extruding Polylactic Acid Using Open Source 3d Printing. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. Thingiverse is a universe of things. The result of poor extrusion calibration. The 3d printer is a great invention. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. With this process, we designed these experimental projects that. Dual extrusion is the process of 3d printing with multiple filaments. I think this might have to do with the filament acting like a spring inside the bowden. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. It only takes a minute to sign up. Download files and build them with your 3d printer, laser cutter, or cnc. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. 3d printer direct drive extruder assembly for fdm 3d printers.

In 3d Printing Does The Bernouilli Equation Mean That 1 75mm Filament Drive Has Less Force On The Extruder Gear Than 3 0mm Mathematics Stack Exchange : The 3D Printer Is A Great Invention.

3d Printer Extruder Calibration Steps Per Mm 3daddict. Dual extrusion is the process of 3d printing with multiple filaments. It only takes a minute to sign up. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Thingiverse is a universe of things. Download files and build them with your 3d printer, laser cutter, or cnc. 3d printer direct drive extruder assembly for fdm 3d printers. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The 3d printer is a great invention. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters The result of poor extrusion calibration. With this process, we designed these experimental projects that. I think this might have to do with the filament acting like a spring inside the bowden. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies.

Calibrating Your Makerbot Using Mattercontrol Matterhackers , The Above Illustration Is Sourced From Desktop Metal (Bound Metal Deposition™.

Adventures In 3 D Printing Calculating The Flow Rate Value. 3d printer direct drive extruder assembly for fdm 3d printers. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. Download files and build them with your 3d printer, laser cutter, or cnc. Thingiverse is a universe of things. The result of poor extrusion calibration. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The 3d printer is a great invention. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. It only takes a minute to sign up. With this process, we designed these experimental projects that. I think this might have to do with the filament acting like a spring inside the bowden. Dual extrusion is the process of 3d printing with multiple filaments. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

3d Printing Speed How Fast Can 3d Printers Go All3dp , Moved Printer Configuration To Printer_Conf.sCad.

How To Calculate Extrusion Multiplier Cincinnati Incorporated. It only takes a minute to sign up. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters Download files and build them with your 3d printer, laser cutter, or cnc. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. The result of poor extrusion calibration. Dual extrusion is the process of 3d printing with multiple filaments. 3d printer direct drive extruder assembly for fdm 3d printers. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. Thingiverse is a universe of things. I think this might have to do with the filament acting like a spring inside the bowden. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The 3d printer is a great invention. With this process, we designed these experimental projects that.

Solved 4 A Dr K Synthesized A New Polymer Material Fo Chegg Com . Dual Extrusion Is The Process Of 3D Printing With Multiple Filaments.

Rarely Adjusted Slicer Setting Makes A Difference Hackaday. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. Thingiverse is a universe of things. The result of poor extrusion calibration. 3d printer direct drive extruder assembly for fdm 3d printers. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters With this process, we designed these experimental projects that. The 3d printer is a great invention. It only takes a minute to sign up. Dual extrusion is the process of 3d printing with multiple filaments. I think this might have to do with the filament acting like a spring inside the bowden. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. Download files and build them with your 3d printer, laser cutter, or cnc.

Gels Free Full Text Extrusion Based 3d Printing Of Poly Ethylene Glycol Diacrylate Hydrogels Containing Positively And Negatively Charged Groups Html , I Allows The User To Print (Almost)Anything He/She Could Imagine!

Calculating E Steps Deviousweb. The result of poor extrusion calibration. I think this might have to do with the filament acting like a spring inside the bowden. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. With this process, we designed these experimental projects that. It only takes a minute to sign up. Dual extrusion is the process of 3d printing with multiple filaments. Thingiverse is a universe of things. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. The 3d printer is a great invention. 3d printer direct drive extruder assembly for fdm 3d printers. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Download files and build them with your 3d printer, laser cutter, or cnc.

3d Printer Extruder Calibration Steps Per Mm 3daddict , Explaining The Close Relationship Between Nozzle.

Pdf Development Of Plastic Filament Extruder For 3d Printing. Download files and build them with your 3d printer, laser cutter, or cnc. I think this might have to do with the filament acting like a spring inside the bowden. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. The 3d printer is a great invention. Dual extrusion is the process of 3d printing with multiple filaments. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The result of poor extrusion calibration. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. Thingiverse is a universe of things. 3d printer direct drive extruder assembly for fdm 3d printers. It only takes a minute to sign up. With this process, we designed these experimental projects that. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time.

Coupling 3d Printing With Hot Melt Extrusion To Produce Controlled Release Tablets Sciencedirect : However, After An Extrusion Like G1 E20 F900 I Have To Use Longer Retractions To Get A Clean Break.

Pdf Fabrication Of Basic Screw Extruder To Manufacture 3d Printers Filament. The result of poor extrusion calibration. 'flow rate' is a slicer setting that tells the 3d printer how much plastic to extrude. The 3d printer is a great invention. Download files and build them with your 3d printer, laser cutter, or cnc. Learn about the different stereolithography (sla) 3d printers, materials, applications, and how sla compares to other types of 3d printing technologies. I think this might have to do with the filament acting like a spring inside the bowden. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. 3d printer direct drive extruder assembly for fdm 3d printers. The simplest way to understand flow rate (aka extrusion multiplier) is that it multiplies how much plastic the 3d printer is told to and also shared this instructional video for flow rate calculation based on two perimeters Thingiverse is a universe of things. It only takes a minute to sign up. You can mix colors or different materials with a print head that has two extruders and it's not actually faster at printing because its still using only one extruder at a time. Dual extrusion is the process of 3d printing with multiple filaments. With this process, we designed these experimental projects that. However, after an extrusion like g1 e20 f900 i have to use longer retractions to get a clean break.