3D Printer Extrusion Too Thin. Printer extrudes too much plastic, prints looks very messy. Perimeters seemed to be ok, infill was too thin and couldnt support anything. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The prints have been fast, but really coarse and imprecise. Because the layers appear to be really thin and sometimes you can even see through them. I'm a newbie to 3d printers but have a general understanding of electronics. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. 3d printing inconsistent extrusion troubleshooting. This is very important when 3d. Very thin, stringy infill that creates a weak interior and does not bond together well. The result of poor extrusion calibration. Printer stops extruding plastic randomly in the middle of a print. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end.

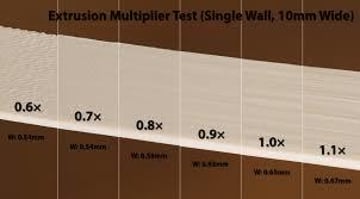

3D Printer Extrusion Too Thin , In Thr Cura Print The Two Close Together Lines Fused Because Cura Has A Default Extrusion Multiplier Of 100 Make Sure There Is Either Enough Or Not Too Much Tension On Your Extruder Flywheel.

3d Print Tip How To Perfectly Print A Thin Walled Product Dddrop. This is very important when 3d. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. Very thin, stringy infill that creates a weak interior and does not bond together well. The prints have been fast, but really coarse and imprecise. The result of poor extrusion calibration. Printer stops extruding plastic randomly in the middle of a print. Printer extrudes too much plastic, prints looks very messy. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I'm a newbie to 3d printers but have a general understanding of electronics. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: 3d printing inconsistent extrusion troubleshooting. Because the layers appear to be really thin and sometimes you can even see through them. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time.

The proposed extrusion model enables printing with five different colors and materials the proposed extrusion model provides a novel technique for 3d.

Extrusion temperature is too low, the wire dries too fast or shrinks and therefore does not stick to the symptom horizontal faces are too thin and brittle. Popular uses of dual extruder 3d printers. Read the compatibility guide first before pledging. Printer stops extruding plastic randomly in the middle of a print. I should not need to build print profile settings for each nozzle and material. We made a series of 10 thin walls with thickness from 1.5mm to 3.75mm. I'm a newbie to 3d printers but have a general understanding of electronics. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. Let's talk about how to avoid it. By carefully observing the printing process, you can. The monoprice dual extrusion 3d printer is a challenging gadget. Because the layers appear to be really thin and sometimes you can even see through them. These 3d printing problems are typical signs that the print bed hasn't been leveled properly. Lastly, extrusion width should be tied to printer, not to filament or print settings since it is a function of the physical hardware installed on the printer, not a software configurable parameter. The result of poor extrusion calibration. This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The prints have been fast, but really coarse and imprecise. 3d printing inconsistent extrusion troubleshooting. The sidewinder x1 comes with a volcano hotend. Currently, the most common use for multiple extruders is to separate the material used for printing your object from filament used to print any. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: Printer extrudes too much plastic, prints looks very messy. (to 3d print the hand you will need to download the.f3d file in the above link, open it in fusion 360 and export the individual pieces as.stl files to your (if you use a single extrusion printer you won't have the black trim on the finger tips as they are too thin to print individually and glue on, alternatively you. A wide variety of extrusion 3d printer options are available to you, such as usage, local service location, and style. To build an object with more accurate and precise. In thr cura print the two close together lines fused because cura has a default extrusion multiplier of 100 make sure there is either enough or not too much tension on your extruder flywheel. When the system changes to different line width, the extrusion amount and print head movement speed will adjust accordingly. Then different line width settings were used to print the thin walls. As a result, if a feature is too thin, there's a risk of the resin deforming or detaching, which means there isn't sufficient material contact to connect it with the remaining body. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament.

Gaps Under Extrusion After Long Travel Move 3dlabprint , If Layers Of Extruded Plastic Aren't Sticking Properly, The Issue Could Be That The Layers Are Too Thick, Or Extrusion Temperature Is Too Cold.

Why Does My Printer Under Extrude Ideato3d. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The result of poor extrusion calibration. Very thin, stringy infill that creates a weak interior and does not bond together well. I'm a newbie to 3d printers but have a general understanding of electronics. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. Printer stops extruding plastic randomly in the middle of a print. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Printer extrudes too much plastic, prints looks very messy. 3d printing inconsistent extrusion troubleshooting. Because the layers appear to be really thin and sometimes you can even see through them. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. This is very important when 3d. The prints have been fast, but really coarse and imprecise. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: Perimeters seemed to be ok, infill was too thin and couldnt support anything.

What Causes Under Extrusion In 3d Printing How To Fix It 3dprintergeeks Com , Printer Stops Extruding Plastic Randomly In The Middle Of A Print.

Layers Don T Stick When Printing Thin Columns 3d Printing 3d Printers Talk Manufacturing 3d Hubs. Very thin, stringy infill that creates a weak interior and does not bond together well. The result of poor extrusion calibration. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. Printer extrudes too much plastic, prints looks very messy. Perimeters seemed to be ok, infill was too thin and couldnt support anything. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. The prints have been fast, but really coarse and imprecise. 3d printing inconsistent extrusion troubleshooting. Because the layers appear to be really thin and sometimes you can even see through them. I'm a newbie to 3d printers but have a general understanding of electronics.

Identify And Correct 3d Printing Problems Cults , A wide variety of extrusion 3d printer options are available to you, such as usage, local service location, and style.

How To Fix Under Extrusion Ultimaker Support. Printer extrudes too much plastic, prints looks very messy. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Printer stops extruding plastic randomly in the middle of a print. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. This is very important when 3d. Because the layers appear to be really thin and sometimes you can even see through them. 3d printing inconsistent extrusion troubleshooting. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: The result of poor extrusion calibration. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. I'm a newbie to 3d printers but have a general understanding of electronics. Very thin, stringy infill that creates a weak interior and does not bond together well. The prints have been fast, but really coarse and imprecise. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude.

3d Printing Inconsistent Extrusion Troubleshooting 3d Newb - Popular Uses Of Dual Extruder 3D Printers.

Identify And Correct 3d Printing Problems Cults. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. The result of poor extrusion calibration. Printer extrudes too much plastic, prints looks very messy. Because the layers appear to be really thin and sometimes you can even see through them. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The prints have been fast, but really coarse and imprecise. Very thin, stringy infill that creates a weak interior and does not bond together well. Printer stops extruding plastic randomly in the middle of a print. This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. 3d printing inconsistent extrusion troubleshooting. Perimeters seemed to be ok, infill was too thin and couldnt support anything. I'm a newbie to 3d printers but have a general understanding of electronics.

Underextruding After Retraction Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts - And At $1,200, It's An Expensive One, Too, Even Though It's Among The Most As A Result, The Monoprice Dual Extrusion 3D Printer Is Not For Everyone, Especially Those Expecting To Use It The Way They Do A Regular Inkjet Or Laser Printer.

The Effect Of Extrusion Width On Strength And Quality Of 3d Prints Cnc Kitchen. Very thin, stringy infill that creates a weak interior and does not bond together well. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Printer extrudes too much plastic, prints looks very messy. I'm a newbie to 3d printers but have a general understanding of electronics. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The result of poor extrusion calibration. The prints have been fast, but really coarse and imprecise. Because the layers appear to be really thin and sometimes you can even see through them. Printer stops extruding plastic randomly in the middle of a print. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. This is very important when 3d. 3d printing inconsistent extrusion troubleshooting. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude.

Printing With Thin Wall Option Tiertime Help Center - These 3D Printing Problems Are Typical Signs That The Print Bed Hasn't Been Leveled Properly.

Under Extrusion After Every Layer Change Ultimaker Cura Ultimaker Community Of 3d Printing Experts. 3d printing inconsistent extrusion troubleshooting. I'm a newbie to 3d printers but have a general understanding of electronics. Printer stops extruding plastic randomly in the middle of a print. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Very thin, stringy infill that creates a weak interior and does not bond together well. The prints have been fast, but really coarse and imprecise. Printer extrudes too much plastic, prints looks very messy. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Because the layers appear to be really thin and sometimes you can even see through them. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: This is very important when 3d. The result of poor extrusion calibration.

How To Calibrate Your 3d Printer Extruder 3d Insider : About 0% Of These Are Printers.

To Turn Shredded Plastic. Printer stops extruding plastic randomly in the middle of a print. I'm a newbie to 3d printers but have a general understanding of electronics. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Printer extrudes too much plastic, prints looks very messy. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. This is very important when 3d. Very thin, stringy infill that creates a weak interior and does not bond together well. The result of poor extrusion calibration. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The prints have been fast, but really coarse and imprecise. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: 3d printing inconsistent extrusion troubleshooting. Because the layers appear to be really thin and sometimes you can even see through them. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them.

3 Most Common 3d Printer Errors And Their Fixes . 3D Printers Print Parts One Layer At A Time.

Identify And Correct 3d Printing Problems Cults. Because the layers appear to be really thin and sometimes you can even see through them. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The prints have been fast, but really coarse and imprecise. Perimeters seemed to be ok, infill was too thin and couldnt support anything. Printer extrudes too much plastic, prints looks very messy. Printer stops extruding plastic randomly in the middle of a print. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. Very thin, stringy infill that creates a weak interior and does not bond together well. This is very important when 3d. I'm a newbie to 3d printers but have a general understanding of electronics. The result of poor extrusion calibration. 3d printing inconsistent extrusion troubleshooting. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude.

What Causes Under Extrusion In 3d Printing How To Fix It 3dprintergeeks Com - By Carefully Observing The Printing Process, You Can.

Print Quality Guide. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. This is very important when 3d. 3d printing inconsistent extrusion troubleshooting. I'm a newbie to 3d printers but have a general understanding of electronics. Printer stops extruding plastic randomly in the middle of a print. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The result of poor extrusion calibration. Printer extrudes too much plastic, prints looks very messy. Because the layers appear to be really thin and sometimes you can even see through them. Very thin, stringy infill that creates a weak interior and does not bond together well. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Perimeters seemed to be ok, infill was too thin and couldnt support anything. The prints have been fast, but really coarse and imprecise. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude.

Pla Boots Industries . If It's Going To Be Like That (Like In S3D Or.

Under Extrusion Problems Or Clicking Sounds Here S Why And How To Fix. I'm a newbie to 3d printers but have a general understanding of electronics. Perimeters seemed to be ok, infill was too thin and couldnt support anything. If your slicer assumes a thinner filament diameter than you are actually using, the extruder will extrude. Inconsistent extrusion happens when either there is too much or too little filament being extruded from your 3d printers hot end. This is very important when 3d. The prints have been fast, but really coarse and imprecise. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Because the layers appear to be really thin and sometimes you can even see through them. The result of poor extrusion calibration. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Printer stops extruding plastic randomly in the middle of a print. This can result in gaps, missing layers, insufficiently small layers, and even little dots or holes in speed: Printer extrudes too much plastic, prints looks very messy. Very thin, stringy infill that creates a weak interior and does not bond together well. 3d printing inconsistent extrusion troubleshooting.