3D Printer Infill Density. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. To understand infill, think about the doors in your home. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Infill provides the 3d print with internal support as the printer builds each layer. A low infill print will feel cheap and weak, while. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill 3d printing is a compromise between these two positions. Infill percentage in 3d printing. Basically the final 3d printed model will have different infill densities depending on the region of the model. Very few doors that are mass. All3dp is an editorially independent publication.

3D Printer Infill Density , 1938 Infill Density 3D Models.

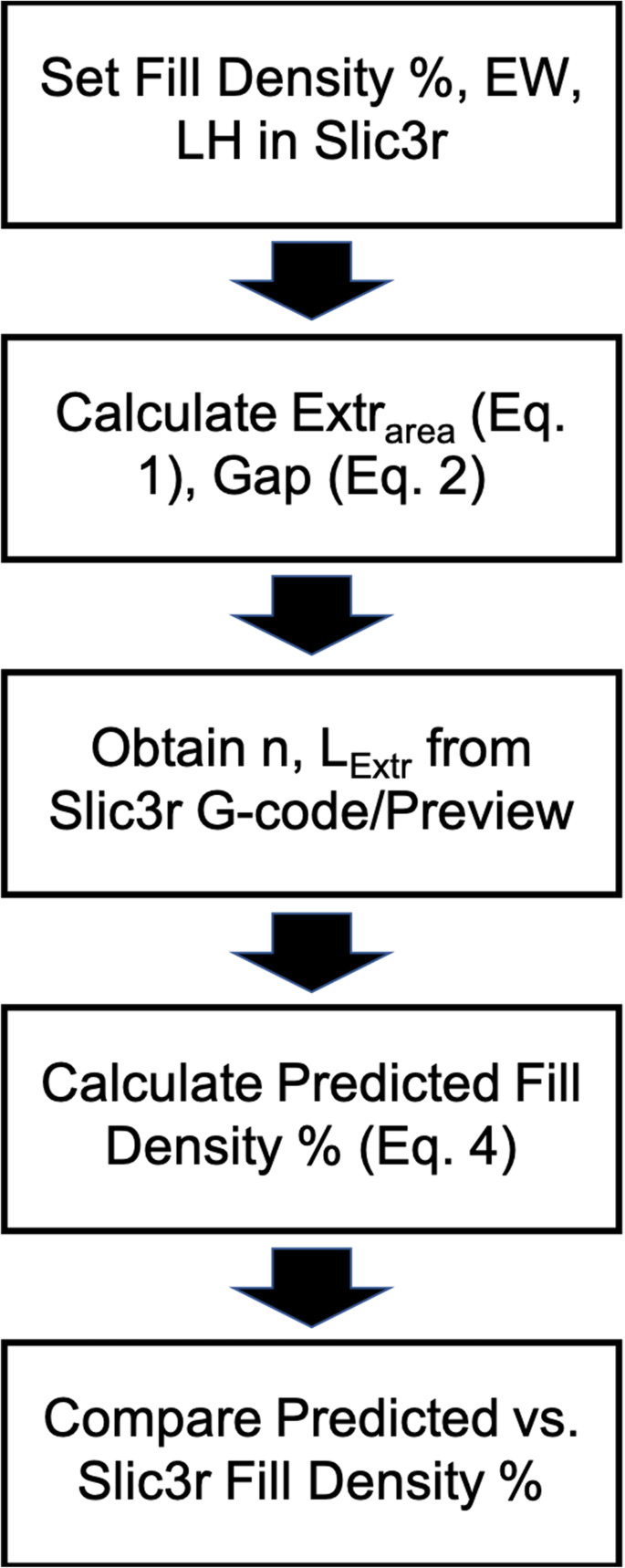

Understanding The Relationship Between Slicing And Measured Fill Density In Material Extrusion 3d Printing Towards Precision Porosity Constructs For Biomedical And Pharmaceutical Applications Springerlink. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. A low infill print will feel cheap and weak, while. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Editorial content, on principle, can not be bought or influenced. Infill 3d printing is a compromise between these two positions. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. To understand infill, think about the doors in your home. Very few doors that are mass. Basically the final 3d printed model will have different infill densities depending on the region of the model. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).

The best value is 20%;

Moroccan stars and catfill showed poorer performance in terms of strength and while the tests conducted only covered a small range of the possible materials and machines used today in desktop 3d printing, it does offer a. This article should list the major 3d printer filaments that are available for 3d printing machines. Low infill percentages reduce material use and make the object lighter, while more. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill print speed therefore can be reduced to reduce print time since this area is not visible. 10 just click on the icons, download the file(s) and print them on your 3d printer Basically the final 3d printed model will have different infill densities depending on the region of the model. It should overlap with the section that you want to change the infill for. Infill 3d printing is a compromise between these two positions. Most 3d printers use some form of detachable print base. The mechanical properties would reflect the way a 3d printer creates a smooth shell of a part with lightweight but weaker core structure. Consider a print with low infill that is going to be drilled and then screwed to another surface. 1938 infill density 3d models. The parts are constructed using polylactic acid (pla) material with the cura software program from ultimaker 3d printer. This can this part had 10% infill and 3 bottom/top layers at.25mm layer height which was not enough for a smooth top surface. I want to be able to have a print be very bottom heavy and have like say 50% infill at the bottom but drop down to like 15 or 20 at i think you still have to manually input the layer height/infill density for all sections though. The infill serves as the internal triangular infill: This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Because hexagonal is more demanding on the printer (more directional changes), we suggest using linear or diagonal. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill percentage in 3d printing. At a low infill %, we show that all three are fairly equivalent. Triangular infill is the strongest infill pattern because triangles are the strongest shape. Gaps between the outline of the part and the outer solid infill layers. Doing this would allow users to run stress analysis on 3d printed parts and to. A low infill print will feel cheap and weak, while. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Infill provides the 3d print with internal support as the printer builds each layer. The infill the amount of material that occupies the internal part of the piece. Properties would include wall thickness, filament type, infill density, and infill type.

What Is Infill In The 3d Printing Settings Flashforge , 10 Just Click On The Icons, Download The File(S) And Print Them On Your 3D Printer

Slic3r Manual Print Settings. Infill 3d printing is a compromise between these two positions. Editorial content, on principle, can not be bought or influenced. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill percentage in 3d printing. To understand infill, think about the doors in your home. Very few doors that are mass. The infill the amount of material that occupies the internal part of the piece. Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. Basically the final 3d printed model will have different infill densities depending on the region of the model. A low infill print will feel cheap and weak, while. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

Paper Direct 3d Printing Of Highly Anisotropic Flexible Constriction Resistive Sensors For Multidirectional Proprioception In Soft Robots Robotics And Autonomous Systems Group . The Infill The Amount Of Material That Occupies The Internal Part Of The Piece.

Gradient Infill For 3d Prints Cnc Kitchen. Infill percentage in 3d printing. Very few doors that are mass. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). To understand infill, think about the doors in your home. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Infill 3d printing is a compromise between these two positions. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer.

Gradient Infill For 3d Prints Cnc Kitchen : Best infill for strength vs material used.

Slicer 3d Printing Wikipedia. The infill the amount of material that occupies the internal part of the piece. Editorial content, on principle, can not be bought or influenced. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. To understand infill, think about the doors in your home. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. A low infill print will feel cheap and weak, while. Very few doors that are mass. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Infill percentage in 3d printing. Infill 3d printing is a compromise between these two positions. Basically the final 3d printed model will have different infill densities depending on the region of the model.

Mattercontrol Help General , Shell And Infill Properties Impact The Performance And Cost Of Fdm 3D Printing.

3d Printing Infill Archives Perfect 3d Printing Filament. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). To understand infill, think about the doors in your home. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Editorial content, on principle, can not be bought or influenced. A low infill print will feel cheap and weak, while. Very few doors that are mass. Infill 3d printing is a compromise between these two positions. Basically the final 3d printed model will have different infill densities depending on the region of the model. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

3d Print Infill Patterns Explained The 3d Bros : For Each Plastic, Slicer Settings Must Be Adapted.

3d Printed Display Tray For Infill Pattern And Infill Density By Kronr Pinshape. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. Infill 3d printing is a compromise between these two positions. Infill percentage in 3d printing. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. All3dp is an editorially independent publication. Very few doors that are mass. The infill the amount of material that occupies the internal part of the piece. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. Basically the final 3d printed model will have different infill densities depending on the region of the model. To understand infill, think about the doors in your home. A low infill print will feel cheap and weak, while. Editorial content, on principle, can not be bought or influenced. Infill provides the 3d print with internal support as the printer builds each layer.

Different Fill Density Percentage On 3d Printer Razlichna Procentna Pltnost Na 3d Printer Prusai3mk3 Prusa 3dprinting 3d Prusa : Check And Adjust The Fill Density.

How To Use 3d Print Infill Settings Increase Strength Save Filament. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. All3dp is an editorially independent publication. Infill 3d printing is a compromise between these two positions. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. Very few doors that are mass. A low infill print will feel cheap and weak, while. Basically the final 3d printed model will have different infill densities depending on the region of the model. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. To understand infill, think about the doors in your home.

3d Printing Infill Archives Perfect 3d Printing Filament . Furthermore, Hexagonal Infills Start To Look Very Similar To Linear Past 30% Infill.

3d Scanning And Printing. Infill 3d printing is a compromise between these two positions. Infill provides the 3d print with internal support as the printer builds each layer. To understand infill, think about the doors in your home. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill the amount of material that occupies the internal part of the piece. Very few doors that are mass. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Basically the final 3d printed model will have different infill densities depending on the region of the model. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. A low infill print will feel cheap and weak, while.

Change Infill Density In A Specific Section On A 3d Model For 3d Printing 8 Steps Instructables : This Can This Part Had 10% Infill And 3 Bottom/Top Layers At.25Mm Layer Height Which Was Not Enough For A Smooth Top Surface.

Infill For Fdm 3d Printing 3 Space. Very few doors that are mass. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. To understand infill, think about the doors in your home. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. A low infill print will feel cheap and weak, while. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. All3dp is an editorially independent publication. Basically the final 3d printed model will have different infill densities depending on the region of the model. Editorial content, on principle, can not be bought or influenced. Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The infill the amount of material that occupies the internal part of the piece. Infill 3d printing is a compromise between these two positions.

Infill For Fdm 3d Printing 3 Space , I Want To Be Able To Have A Print Be Very Bottom Heavy And Have Like Say 50% Infill At The Bottom But Drop Down To Like 15 Or 20 At I Think You Still Have To Manually Input The Layer Height/Infill Density For All Sections Though.

The Best Cura Infill Pattern For Your Needs All3dp. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill 3d printing is a compromise between these two positions. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Very few doors that are mass. Basically the final 3d printed model will have different infill densities depending on the region of the model. Infill provides the 3d print with internal support as the printer builds each layer. To understand infill, think about the doors in your home. A low infill print will feel cheap and weak, while. Editorial content, on principle, can not be bought or influenced. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density.

Cura 2 6 Different Infills In The Same Print Ideato3d , The Infill Print Speed Therefore Can Be Reduced To Reduce Print Time Since This Area Is Not Visible.

Gradient Infill For 3d Prints Cnc Kitchen. To understand infill, think about the doors in your home. Infill 3d printing is a compromise between these two positions. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. A low infill print will feel cheap and weak, while. All3dp is an editorially independent publication. Very few doors that are mass. Basically the final 3d printed model will have different infill densities depending on the region of the model. Infill provides the 3d print with internal support as the printer builds each layer. The workflow was based in the following in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill density. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. Infill density is the amount of filament printed inside the object, and this directly relates to 3d printer infill percentage and overall object strength. Without infill, printing the top layers would be very difficult, as the plastic would the density of your infill makes a huge difference in the weight and durability of your print.