3D Printer Making Human Organs. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. With new developments in the field of biofabrication, it is now possible to print out human organs. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. ► subscribe for more tech & culture. Scientists are racing to make replacement human organs with 3d printers. Video, 00:02:22making human organs through 3d printing. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. It currently makes them for testing, but in future, aims to make human organs for transplantation.

3D Printer Making Human Organs - The Fear A Person May Feel When Told He Or She Needs A New Lung Or Kidney May Soon By A Thing Of The Past As Medical Science Is Quickly Learning How To Use 3D Printing Technology To Build Replacements.

How 3d Bioprinting Could Revolutionize Organ Replacement Bostonomix. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. With new developments in the field of biofabrication, it is now possible to print out human organs. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Scientists are racing to make replacement human organs with 3d printers. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. ► subscribe for more tech & culture. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Video, 00:02:22making human organs through 3d printing. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. It currently makes them for testing, but in future, aims to make human organs for transplantation.

Human organs from a 3d printer.

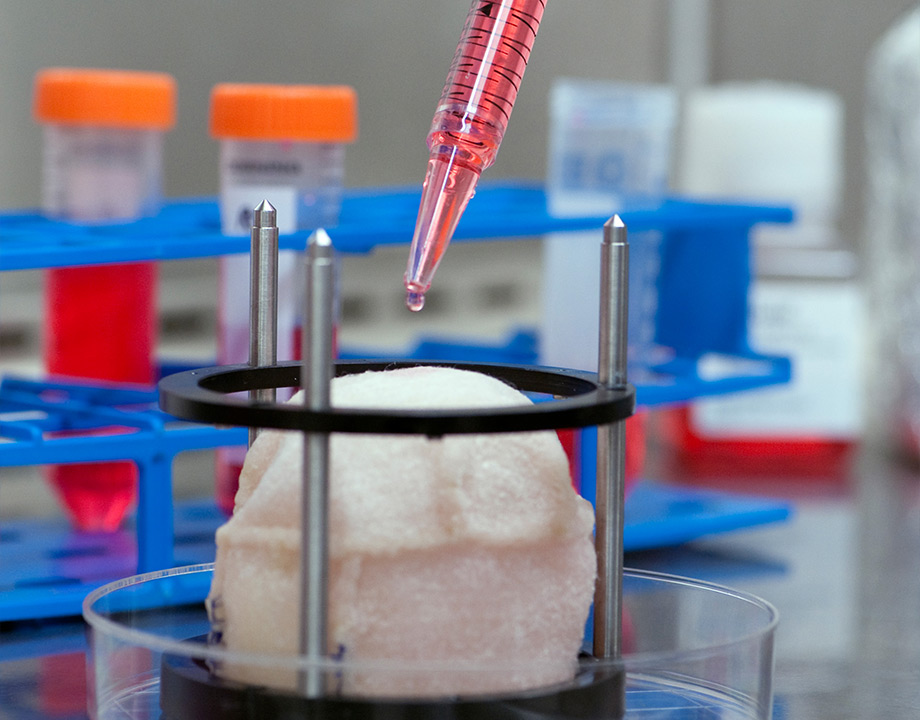

In the future, implantable organs may be printed. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. That makes it very difficult to print a heart in an environment like earth where you have gravity, because the organ collapses in on itself. ► subscribe for more tech & culture. The cells used by the device need to be. The test structures included a human femur, a human coronary artery, a. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Efforts are being made by researchers and scientists; In the future, implantable organs may be printed. Human organ transplants, printed on 3d printers, could be functioning in 15 years, according to the vice president of russia's skolkovo they are set to print other organs, and are now talking about making a kidney, a liver. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. The goal of developing functioning whole organs, such as kidneys, livers or hearts, is becoming more and more of a reality. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. With new developments in the field of biofabrication, it is now possible to print out human organs. Scientists are racing to make replacement human organs with 3d printers. Video, 00:02:22making human organs through 3d printing. So if we can print bones, blood vessels, organs, and skin, doesn't it make sense that the next thing to think about is printing a full human being? The future is here…well, almost: First a layer of cells is laid down by the printer, followed by a layer of. Wake forest institute for regenerative medicine. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. It is now at the lab level, but it will. We may have to wait for another couple of years to witness the real progress in bioprinting and more specifically 3d printing industry. Now we can print organs and purchase a 3d printer for home use on small projects. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Should we even be printing human organs (not everyone thinks so)? The fear a person may feel when told he or she needs a new lung or kidney may soon by a thing of the past as medical science is quickly learning how to use 3d printing technology to build replacements. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Human organs from a 3d printer. What uses could this possibly serve?

Coming Soon To A 3d Printer Near You Human Tissue And Organs Quartz : The Test Structures Included A Human Femur, A Human Coronary Artery, A.

A New Approach To 3d Printing Human Organs Cosmos Magazine. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. ► subscribe for more tech & culture. Video, 00:02:22making human organs through 3d printing. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. With new developments in the field of biofabrication, it is now possible to print out human organs. It currently makes them for testing, but in future, aims to make human organs for transplantation. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Scientists are racing to make replacement human organs with 3d printers. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts.

A Swifter Way Towards 3d Printed Organs . Atala's 3D Printer Can Inject Cells Suspended In Gel, And Those Cells Can Be Anything From Mouse Muscle To Rabbit Cartilage To Human Stem Cells Filtered From Amniotic.

Medical 3d Printing Applications 3d Hubs. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. It currently makes them for testing, but in future, aims to make human organs for transplantation. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. With new developments in the field of biofabrication, it is now possible to print out human organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Video, 00:02:22making human organs through 3d printing.

Rethinking Objects And Form Are Key To 3d Printing Revolution Reuters , Now we can print organs and purchase a 3d printer for home use on small projects.

This 3d Printer Could Make New Organs For Transplant Patients Business Insider. Video, 00:02:22making human organs through 3d printing. ► subscribe for more tech & culture. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Scientists are racing to make replacement human organs with 3d printers. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. It currently makes them for testing, but in future, aims to make human organs for transplantation. With new developments in the field of biofabrication, it is now possible to print out human organs. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways.

3d Printed Organs Are A Heartbeat Closer To Reality : With New Developments In The Field Of Biofabrication, It Is Now Possible To Print Out Human Organs.

Top 20 3d Bioprinting Startups. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. ► subscribe for more tech & culture. Video, 00:02:22making human organs through 3d printing. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. It currently makes them for testing, but in future, aims to make human organs for transplantation. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Scientists are racing to make replacement human organs with 3d printers. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. With new developments in the field of biofabrication, it is now possible to print out human organs. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways.

University Of Wollongong 3d Prints Human Ears Using Stem Cells , Human Organs From A 3D Printer.

New Progress In The Biggest Challenge With 3d Printed Organs. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. With new developments in the field of biofabrication, it is now possible to print out human organs. Scientists are racing to make replacement human organs with 3d printers. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. ► subscribe for more tech & culture. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. It currently makes them for testing, but in future, aims to make human organs for transplantation. Video, 00:02:22making human organs through 3d printing.

3d Bioprinting Breakthrough Leads To Full Scale Functioning Heart Parts , 3D Bioprinting, The Process Of Using Bioink Composed Of Tissue Or Human Cells, Has Come A Long Way Over The Last Decade.

A Swifter Way Towards 3d Printed Organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Video, 00:02:22making human organs through 3d printing. With new developments in the field of biofabrication, it is now possible to print out human organs. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. ► subscribe for more tech & culture. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Scientists are racing to make replacement human organs with 3d printers. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. It currently makes them for testing, but in future, aims to make human organs for transplantation. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced.

3d Printing Offers Hope Of Building Human Organs From Scratch Financial Times : What Uses Could This Possibly Serve?

3d Printing Biology Research Journey Back To Earth In Spacex S Dragon Nasa. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Scientists are racing to make replacement human organs with 3d printers. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. ► subscribe for more tech & culture. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. With new developments in the field of biofabrication, it is now possible to print out human organs. It currently makes them for testing, but in future, aims to make human organs for transplantation. Video, 00:02:22making human organs through 3d printing.

3d Printing Of Human Organs Future Perspective Ip Scenario Aranca : It Is Now At The Lab Level, But It Will.

Top 20 3d Bioprinting Startups. ► subscribe for more tech & culture. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. Scientists are racing to make replacement human organs with 3d printers. With new developments in the field of biofabrication, it is now possible to print out human organs. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. Video, 00:02:22making human organs through 3d printing. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. It currently makes them for testing, but in future, aims to make human organs for transplantation. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to.

The Science Fiction World Of 3d Printed Organs , One Day This Will Be Possible, And With A Desperate Global Shortage Of Organs For Transplant, The Medical Industry Is Like Other Forms Of 3D Printing, Living Tissue Is Printed Layer By Layer.

3d Printing Biology Research Journey Back To Earth In Spacex S Dragon Nasa. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Scientists are racing to make replacement human organs with 3d printers. ► subscribe for more tech & culture. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. It currently makes them for testing, but in future, aims to make human organs for transplantation. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. With new developments in the field of biofabrication, it is now possible to print out human organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Video, 00:02:22making human organs through 3d printing.

Is 3d Bioprinting The Future Of Tailor Made Medicine 3dnatives : The Future Is Here…Well, Almost:

The Ultimate List Of What We Can 3d Print In Medicine And Healthcare The Medical Futurist. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Hod lipson, the director of the computational synthesis laboratory at the university, has been testing the 3d printer. Scientists are racing to make replacement human organs with 3d printers. But while the technology's possibilities are exciting, already there are instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be. With new developments in the field of biofabrication, it is now possible to print out human organs. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of producing functional human body parts. Swedish firm cellink is at that forefront of producing human ears and noses through 3d printing. It currently makes them for testing, but in future, aims to make human organs for transplantation. 3d printing is a type of additive manufacturing technique wherein, unlike subtractive manufacturing, the material is added layer by layer. ► subscribe for more tech & culture. Video, 00:02:22making human organs through 3d printing. Synthetic organs printed by the digital anatomy printer could replace cadavers as training tools for stratasys wants to replace human organs with synthetic replicas to modernize the teaching the advance in material science for us is making them softer and more flexible and having more control to. As it turns out, printing working human organs is a lot more complex than printing out plastic toys. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs.