3D Printer Over Extrusion Cura. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Let's take a look at cura's extrusion multiplier, which is called flow rate. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Over extrusion is a situation where the 3d printer splotches out too much material. The extruder controls are separate from the rest of the 3d printer. Learn what it is and how it can help fix print issues. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Is there any new setting or a setting that isn't migrated properly that. It usually ends up ruining the design quality of your prints. My printing is a robo3d r1+ using the custom fdm printer profile. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. 3d printers that get even better over time. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Steps to reproduce select a dual extrusion printer and generate the gcode. I referred to this post:

3D Printer Over Extrusion Cura : Is There Any New Setting Or A Setting That Isn't Migrated Properly That.

3d Printer Under Extrusion 3 Simple Solutions All3dp. My printing is a robo3d r1+ using the custom fdm printer profile. It usually ends up ruining the design quality of your prints. Let's take a look at cura's extrusion multiplier, which is called flow rate. I referred to this post: The extruder controls are separate from the rest of the 3d printer. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Learn what it is and how it can help fix print issues. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Is there any new setting or a setting that isn't migrated properly that. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Steps to reproduce select a dual extrusion printer and generate the gcode. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. 3d printers that get even better over time. Over extrusion is a situation where the 3d printer splotches out too much material.

Steps to reproduce select a dual extrusion printer and generate the gcode.

The extruder controls are separate from the rest of the 3d printer. Let's take a look at cura's extrusion multiplier, which is called flow rate. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. The extruder controls are separate from the rest of the 3d printer. Personally the printer is very good printer, but i almost always had under extrusion issues, i finally replaced the extruders with new aluminum mk10 extruders, and now it prints consistent and wonderful. I received my first 3d printer about a week ago. Steps to reproduce select a dual extrusion printer and generate the gcode. Over extrusion is a situation where the 3d printer splotches out too much material. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. It usually ends up ruining the design quality of your prints. 3d printers that get even better over time. Learn what it is and how it can help fix print issues. My printing is a robo3d r1+ using the custom fdm printer profile. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Is there any new setting or a setting that isn't migrated properly that. I referred to this post: Cura is an open source 3d printer slicing application, it is widely used in 3d printing. After i figured out how to use it, i was getting really good prints but i always had 100% would be the worst and 0% would cause the least, but the over extrusion was still present.

How To Multi Color Print On Single Extruder Ender 3 Cura By J07 Thingiverse : The Extruder Controls Are Separate From The Rest Of The 3D Printer.

Ultimaker 2 Over Extruding Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Over extrusion is a situation where the 3d printer splotches out too much material. Steps to reproduce select a dual extrusion printer and generate the gcode. Is there any new setting or a setting that isn't migrated properly that. Let's take a look at cura's extrusion multiplier, which is called flow rate. 3d printers that get even better over time. The extruder controls are separate from the rest of the 3d printer. Learn what it is and how it can help fix print issues. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. It usually ends up ruining the design quality of your prints. I referred to this post: My printing is a robo3d r1+ using the custom fdm printer profile. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again.

How To Multi Color Print On Single Extruder Ender 3 Cura By J07 Thingiverse - Personally The Printer Is Very Good Printer, But I Almost Always Had Under Extrusion Issues, I Finally Replaced The Extruders With New Aluminum Mk10 Extruders, And Now It Prints Consistent And Wonderful.

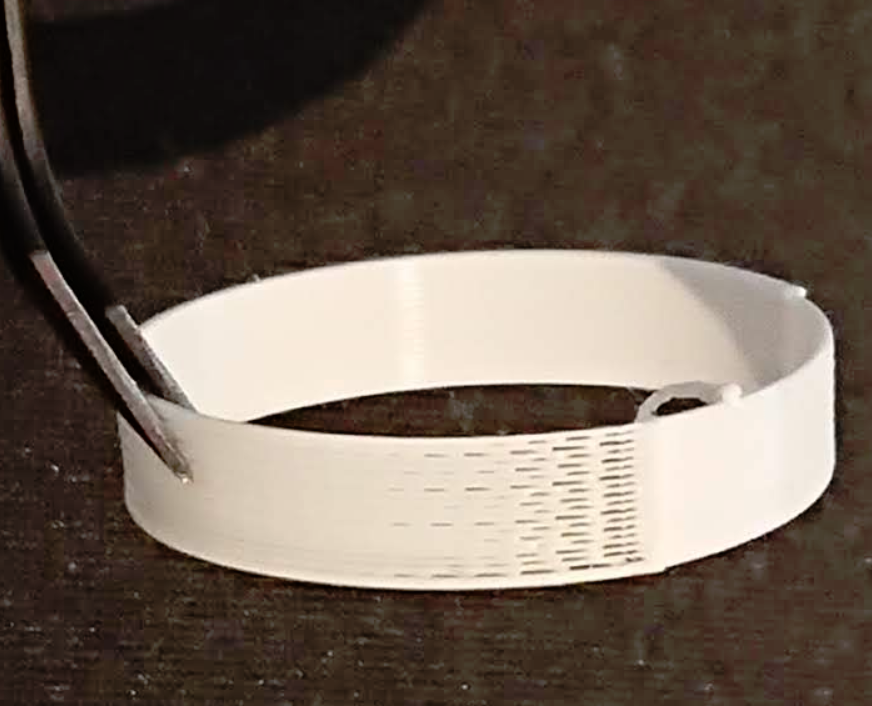

The Walls Of My Prints Are Separating No Matter What I Do My Extrusion Is Now At 105 And It Seems Like It S Over Extruding The Surfaces But The Walls Look Like. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Learn what it is and how it can help fix print issues. Let's take a look at cura's extrusion multiplier, which is called flow rate. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. My printing is a robo3d r1+ using the custom fdm printer profile. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Steps to reproduce select a dual extrusion printer and generate the gcode. Is there any new setting or a setting that isn't migrated properly that. The extruder controls are separate from the rest of the 3d printer.

Be Carefull Using Different Wall Speed Over Extrusion At Start Of The Layer May Happen 3dprinting , Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems.

Why Are There Lines On The Side Of Your 3d Print The 3d Bros. Learn what it is and how it can help fix print issues. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. 3d printers that get even better over time. My printing is a robo3d r1+ using the custom fdm printer profile. The extruder controls are separate from the rest of the 3d printer. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. I referred to this post: Is there any new setting or a setting that isn't migrated properly that. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. It usually ends up ruining the design quality of your prints. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Steps to reproduce select a dual extrusion printer and generate the gcode. Let's take a look at cura's extrusion multiplier, which is called flow rate. Over extrusion is a situation where the 3d printer splotches out too much material. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing.

Stuttering Extrusion At The Start Of Each New Layer Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts . 3D Printers That Get Even Better Over Time.

First Layer Over Extrusion Causes Ender3. 3d printers that get even better over time. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Is there any new setting or a setting that isn't migrated properly that. Steps to reproduce select a dual extrusion printer and generate the gcode. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. My printing is a robo3d r1+ using the custom fdm printer profile. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Let's take a look at cura's extrusion multiplier, which is called flow rate. Learn what it is and how it can help fix print issues. It usually ends up ruining the design quality of your prints. The extruder controls are separate from the rest of the 3d printer. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. I referred to this post: Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Over extrusion is a situation where the 3d printer splotches out too much material.

3d Printer Under Extrusion 3 Simple Solutions All3dp - It Usually Ends Up Ruining The Design Quality Of Your Prints.

3d Printing Transparent Parts Using Fdm Fff Printer Fenneclabs. Learn what it is and how it can help fix print issues. Is there any new setting or a setting that isn't migrated properly that. Steps to reproduce select a dual extrusion printer and generate the gcode. I referred to this post: Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. My printing is a robo3d r1+ using the custom fdm printer profile. 3d printers that get even better over time. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. It usually ends up ruining the design quality of your prints. Let's take a look at cura's extrusion multiplier, which is called flow rate. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Over extrusion is a situation where the 3d printer splotches out too much material. The extruder controls are separate from the rest of the 3d printer. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour.

Blobs And Zits , My Printing Is A Robo3D R1+ Using The Custom Fdm Printer Profile.

Blobs And Zits. My printing is a robo3d r1+ using the custom fdm printer profile. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Over extrusion is a situation where the 3d printer splotches out too much material. Let's take a look at cura's extrusion multiplier, which is called flow rate. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. The extruder controls are separate from the rest of the 3d printer. I referred to this post: Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. 3d printers that get even better over time. It usually ends up ruining the design quality of your prints. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Steps to reproduce select a dual extrusion printer and generate the gcode. Learn what it is and how it can help fix print issues. Is there any new setting or a setting that isn't migrated properly that.

Fix Under Extrusion On Creality Ender 3 Plus Cura 4 4 Plugin Youtube : Personally The Printer Is Very Good Printer, But I Almost Always Had Under Extrusion Issues, I Finally Replaced The Extruders With New Aluminum Mk10 Extruders, And Now It Prints Consistent And Wonderful.

Stringing With Prusaslicer Solved With Cura How Do I Print This Printing Help Prusa3d Forum. Is there any new setting or a setting that isn't migrated properly that. My printing is a robo3d r1+ using the custom fdm printer profile. 3d printers that get even better over time. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. The extruder controls are separate from the rest of the 3d printer. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Steps to reproduce select a dual extrusion printer and generate the gcode. It usually ends up ruining the design quality of your prints. Learn what it is and how it can help fix print issues. I referred to this post: Over extrusion is a situation where the 3d printer splotches out too much material. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Let's take a look at cura's extrusion multiplier, which is called flow rate.

Over Extrusion On Layer Change Fixmyprint . Actual Results After The Last Extrusion Toolpath Of One Extruder, The Extruder Will Stop On Top Of The 3D Print, Waiting For The Other Extruder To Reach The Initial Printing Temperature, This Could Be A 5.

Collaborative Research Team Develops Density Graded Structure For Extrusion 3d Printing Of Functionally Graded Materials 3dprint Com The Voice Of 3d Printing Additive Manufacturing. My printing is a robo3d r1+ using the custom fdm printer profile. Let's take a look at cura's extrusion multiplier, which is called flow rate. Steps to reproduce select a dual extrusion printer and generate the gcode. I referred to this post: Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Is there any new setting or a setting that isn't migrated properly that. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Over extrusion is a situation where the 3d printer splotches out too much material. Learn what it is and how it can help fix print issues. 3d printers that get even better over time. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. It usually ends up ruining the design quality of your prints. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. The extruder controls are separate from the rest of the 3d printer.

Help Me Please Over Extrusion Page 1 3d Printer Discussion Soliforum 3d Printing Community : Cura Is An Open Source 3D Printer Slicing Application, It Is Widely Used In 3D Printing.

Ender 3 Severe Under Extrusion 3d Printing Stack Exchange. It usually ends up ruining the design quality of your prints. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Let's take a look at cura's extrusion multiplier, which is called flow rate. Steps to reproduce select a dual extrusion printer and generate the gcode. Learn what it is and how it can help fix print issues. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. My printing is a robo3d r1+ using the custom fdm printer profile. The extruder controls are separate from the rest of the 3d printer. Is there any new setting or a setting that isn't migrated properly that. Over extrusion is a situation where the 3d printer splotches out too much material. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour. I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. I referred to this post: 3d printers that get even better over time.

How To Multi Color Print On Single Extruder Ender 3 Cura By J07 Thingiverse - After I Figured Out How To Use It, I Was Getting Really Good Prints But I Always Had 100% Would Be The Worst And 0% Would Cause The Least, But The Over Extrusion Was Still Present.

Ender 3 Cura Settings The Best Ender 3 Cura Profile All3dp. It usually ends up ruining the design quality of your prints. Actual results after the last extrusion toolpath of one extruder, the extruder will stop on top of the 3d print, waiting for the other extruder to reach the initial printing temperature, this could be a 5. Over extrusion is a situation where the 3d printer splotches out too much material. Is there any new setting or a setting that isn't migrated properly that. Steps to reproduce select a dual extrusion printer and generate the gcode. Learn what it is and how it can help fix print issues. 3d printers that get even better over time. The extruder controls are separate from the rest of the 3d printer. Without solving this problem, your projects will be susceptible to dimensional inaccuracy, oozing blobs, layer drooping and stringing. Thingiverse groups bibo 3d printers general cura 3.6 dual extrusion problems. My printing is a robo3d r1+ using the custom fdm printer profile. I referred to this post: I upgraded from cura 2.7 to 3.1.0 and i'm getting horrible under extrusion, i'm sure this is the software because i rolled back to 2.7 and everything is working fine again. Let's take a look at cura's extrusion multiplier, which is called flow rate. After reviewing the geeetech a10m 3d printer, i was excited to get my head around how to setup and slice for dual extrusion / dual colour.