3D Printer Plastic Waste. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Supports can lead to a lot of waste plaste. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Even though the suggestions above can help. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Using something like this 3d printer. Shawn, there are various ways to recycle such waste plastics. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Get free expert advice and quotes from trusted suppliers in your area. Finding yourself with a mountain of 3d printer waste? Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Are you looking to buy a 3d printer or 3d scanner? If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Tips for reducing plastic waste. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000.

3D Printer Plastic Waste - If You Have A 3D Printer, Not Only Do You Probably Have Failed Prints And Prints That Are No Longer Needed, But There Are Probably Some Plastic Bottles Around You.

How One 3d Printing Company Is Fighting Plastic Waste Ideas. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Tips for reducing plastic waste. Shawn, there are various ways to recycle such waste plastics. Supports can lead to a lot of waste plaste. Get free expert advice and quotes from trusted suppliers in your area. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Finding yourself with a mountain of 3d printer waste? Even though the suggestions above can help. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Are you looking to buy a 3d printer or 3d scanner? Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Using something like this 3d printer. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste.

Three engineering physics students at the university of british columbia in canada have developed the protocycler, a gadget that can crush a wide range of waste plastic into an excellent clean spool of plastic fiber that can be utilized as a filament of a 3d printer.

We just noticed that there was an obscene amount of waste, said jake boudreau, founder of kindness3d, during an interview. Three engineering physics students at the university of british columbia in canada have developed the protocycler, a gadget that can crush a wide range of waste plastic into an excellent clean spool of plastic fiber that can be utilized as a filament of a 3d printer. Machines like these grind existing plastics down then melt the pieces together into long strands and have you used a 3d printer before? Protocycler comes complete with a grinder to shred your 3d printer waste, a class leading extruder to produce filament. Recycle your 3d printer waste, and make it back into filament. Thingiverse is a universe of things. Protocycler is the first and only system for recycling waste plastic into new filament. The top countries of supplier is china, from which the percentage of 3d printer recycle plastic supply is 100% respectively. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. We just noticed that there was an obscene amount of waste, said jake boudreau, founder of kindness3d, during an interview. The processing machine used to. ··· waste plastic recycling line abs pla 3d printer filament line. Wait, how does plastic waste connect to 3d printing? Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. .of plastic waste ending up in the oceans, landfill or incinerators, whilst simultaneously popularising 3d printing as an educational tool in schools. After that, printers can process them properly. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Even though the suggestions above can help. Supports can lead to a lot of waste plaste. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. The company takes the plastic and then uses a modified paper shredding to cut the lids into smaller pieces. Plastic waste, in particular pet, which is typically found in soda bottles, is becoming abundant in african cities. If you have a 3d printer, not only do you probably have failed prints and prints that are no longer needed, but there are probably some plastic bottles around you. Using something like this 3d printer. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Meanwhile, industrial machines can churn out objects as sophisticated as unmanned airplanes. Get free expert advice and quotes from trusted suppliers in your area. There are 21 suppliers who sells 3d printer recycle plastic on alibaba.com, mainly located in asia. Finding yourself with a mountain of 3d printer waste? Solutions for prototyping to production in plastics. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000.

Plastic Waste 3d Printer Filament Machine Pledgeme - Solutions For Prototyping To Production In Plastics.

5 Ways To Reduce Waste At The Coffee Shop Plastic Waste Recycling Recycled Plastic. Are you looking to buy a 3d printer or 3d scanner? Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Get free expert advice and quotes from trusted suppliers in your area. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Using something like this 3d printer. Tips for reducing plastic waste. Finding yourself with a mountain of 3d printer waste? Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Even though the suggestions above can help. Shawn, there are various ways to recycle such waste plastics. Supports can lead to a lot of waste plaste. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors.

3d Printed Urban Furniture Made From Recycled Plastic All3dp : Get Free Expert Advice And Quotes From Trusted Suppliers In Your Area.

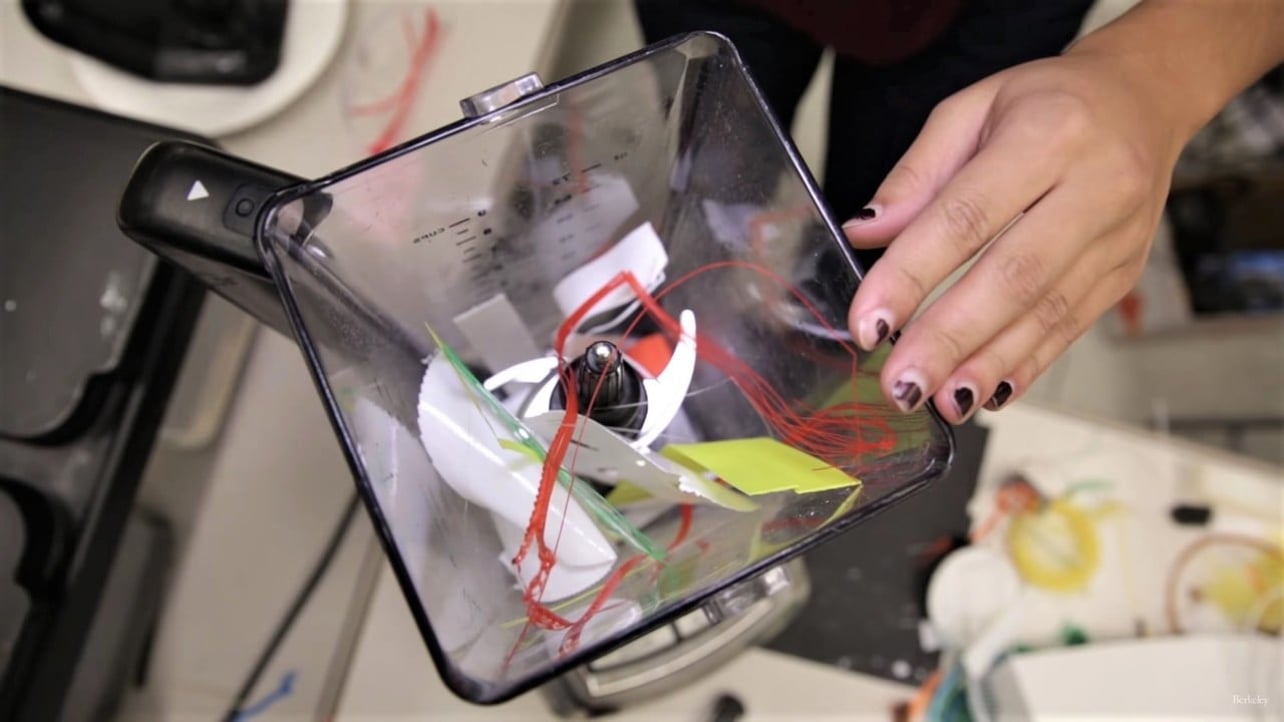

As 3d Printing Grows So Does Need To Reclaim Plastic Waste Berkeley News. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Even though the suggestions above can help. Shawn, there are various ways to recycle such waste plastics. Finding yourself with a mountain of 3d printer waste? Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Supports can lead to a lot of waste plaste. Are you looking to buy a 3d printer or 3d scanner? Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets.

3d Printing Sustainability Solving The Plastic Trash Crisis All3dp , Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets.

Petg Pla Recycling How To Recycle 3d Printer Waste All3dp. Supports can lead to a lot of waste plaste. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Get free expert advice and quotes from trusted suppliers in your area. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Are you looking to buy a 3d printer or 3d scanner? Finding yourself with a mountain of 3d printer waste? Using something like this 3d printer. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Even though the suggestions above can help. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Tips for reducing plastic waste. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Shawn, there are various ways to recycle such waste plastics.

3d Printed Street Furniture Made From Plastic Waste 3dnatives . Join Us As We Chat With Jasper Middendorp Whose Work At Reflow Filament Includes Transforming Plastic Waste Into Filament For 3D Printers, A Way To Bring 3D.

A D O By Mini The Future Of 3d Printing. Tips for reducing plastic waste. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Supports can lead to a lot of waste plaste. Get free expert advice and quotes from trusted suppliers in your area. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Are you looking to buy a 3d printer or 3d scanner? Even though the suggestions above can help. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Using something like this 3d printer. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Shawn, there are various ways to recycle such waste plastics. Finding yourself with a mountain of 3d printer waste? Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets.

Is 3d Printing Increasing The Plastic Pollution Problem : This Brings Things Full Circle:

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcqml73brfvi Hplhmndnpii7bhznbtvc0ipqq Usqp Cau. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Are you looking to buy a 3d printer or 3d scanner? Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Supports can lead to a lot of waste plaste. Tips for reducing plastic waste. Get free expert advice and quotes from trusted suppliers in your area. Shawn, there are various ways to recycle such waste plastics. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Using something like this 3d printer. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Finding yourself with a mountain of 3d printer waste? Even though the suggestions above can help. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says.

Recycle At Home With 3d Printing Machine Design : Finding Yourself With A Mountain Of 3D Printer Waste?

This 3d Printer Can Work Directly With Recycled Plastic Hackster Io. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Are you looking to buy a 3d printer or 3d scanner? Tips for reducing plastic waste. Even though the suggestions above can help. Shawn, there are various ways to recycle such waste plastics. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Get free expert advice and quotes from trusted suppliers in your area. Finding yourself with a mountain of 3d printer waste? If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Supports can lead to a lot of waste plaste. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Using something like this 3d printer.

Zero Waste 3d Printing An Initiative To Collect And Recycle Plastic Left Behind From 3d Printers Youtube , Our Filament Makers Streamline Innovation For Engineers.

Meet One Engineer Transforming Plastic Waste Into The Filament Of The Future Wec 2019. Shawn, there are various ways to recycle such waste plastics. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Are you looking to buy a 3d printer or 3d scanner? If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Supports can lead to a lot of waste plaste. Even though the suggestions above can help. Finding yourself with a mountain of 3d printer waste? Tips for reducing plastic waste. Using something like this 3d printer. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Get free expert advice and quotes from trusted suppliers in your area.

Can We Shift Waste To Value Through 3d Printing In Tanzania . ··· Waste Plastic Recycling Line Abs Pla 3D Printer Filament Line.

3dstartup 3devo Recycling Plastic To Make 3d Printing Filament 3dnatives. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Are you looking to buy a 3d printer or 3d scanner? Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Supports can lead to a lot of waste plaste. Tips for reducing plastic waste. Shawn, there are various ways to recycle such waste plastics. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Using something like this 3d printer. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Get free expert advice and quotes from trusted suppliers in your area. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Even though the suggestions above can help. Finding yourself with a mountain of 3d printer waste?

A D O By Mini The Future Of 3d Printing - Protocycler Uses State Of The Art Extrusion Technology, With Fully Automatic Built In Diameter Feedback.

Tanzania When Plastic Waste Becomes Filament For 3d Printer Afrik 21. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Supports can lead to a lot of waste plaste. Get free expert advice and quotes from trusted suppliers in your area. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Finding yourself with a mountain of 3d printer waste? Even though the suggestions above can help. Using something like this 3d printer. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Shawn, there are various ways to recycle such waste plastics. Tips for reducing plastic waste. Are you looking to buy a 3d printer or 3d scanner? Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d.

Penn State Startup Trimatis Converting Plastic Waste Into 3d Printer Filament Penn State University : Thingiverse Is A Universe Of Things.

Could 3d Printing Reduce Plastic Waste. If a person could shred waste plastic or failed prints to feed into an extruder, the cost of printing material would be greatly reduced, watkins says. Tips for reducing plastic waste. Protocycler is an all in one recycling system for 3d printers, which allows you to make your own filament from recycled waste and virgin plastic pellets. Shawn, there are various ways to recycle such waste plastics. Even though the suggestions above can help. Reduce waste by learning about the recyclability of common 3d tips for reducing plastic waste. Get free expert advice and quotes from trusted suppliers in your area. Supports can lead to a lot of waste plaste. Are you looking to buy a 3d printer or 3d scanner? Finding yourself with a mountain of 3d printer waste? Plastics deposited in recycling bins are all too often destined for oversea plants for final reprocessing they use a polymer melt extrusion process to turn recyclable plastics into 3d printer filaments, which can then be used to manufacture items like water pipe connectors. Join us as we chat with jasper middendorp whose work at reflow filament includes transforming plastic waste into filament for 3d printers, a way to bring 3d. Using something like this 3d printer. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000.