3D Printer Printed Human Organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. The idea of bioprinting human organs is no longer some far off science fiction idea. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. ► subscribe for more tech & culture. The human tissue printed out so far by the. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Traditional 3d printer technology relies on the process of additive manufacturing. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Scientists are racing to make replacement human organs with 3d printers. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements.

3D Printer Printed Human Organs . Similar To Normal 3D Printers It Deposits Cells And Structural And Nutritional Material In The Attempt To Combine Different Tissues To Form Organs.

Silicon Valley Startup 3d Printing Human Organs To Save Lives. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. The idea of bioprinting human organs is no longer some far off science fiction idea. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. The human tissue printed out so far by the. Traditional 3d printer technology relies on the process of additive manufacturing. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. ► subscribe for more tech & culture. Scientists are racing to make replacement human organs with 3d printers. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials.

We would print it with a material that has the mechanical properties that can withstand the pressure of the bones, as well as have some factors that the researchers will now focus on applying pressure to the 3d printed meniscus and monitor how the disc replica would respond in a real human knee.

What uses could this possibly serve? They're developing 3d printers that can also save and change lives by printing out functional human organs. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. You turn a corner in a laboratory, and there's a table full of human aortas. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. However, the printer should be able to print human organs in some 15 years, kaem said. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. They wanted to convert a 3d printer that printed metal into one that could print biological materials. Alibaba.com offers 696 3d printer human products. 216shares1703973d printing organs and body parts to serve as surgical aids is a trend that has been gathering steam within the industry for some time now. 3d printing a human being, if at all possible, is still far off. Medical 3d printer for duplication of human organs. The idea of bioprinting human organs is no longer some far off science fiction idea. Printing a liver and a heart is one thing, but printing an entire body is completely another. Now we can print organs and purchase a 3d printer for home use on small projects. Similar to normal 3d printers it deposits cells and structural and nutritional material in the attempt to combine different tissues to form organs. Scientists are racing to make replacement human organs with 3d printers. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Scientists are using special 3d printers to create living body parts and claim the groundbreaking method will soon allow them to implant printed organs as well. About 0% of these are medical science. Body parts printed thus far include a jaw bone, muscle tissue, and cartilage structures, and perhaps most impressive of all, an incredibly accurate human ear. Sure, 3d printers that can spit out chocolates, create shoes, handcraft cars and help astronauts sound fun and magical, but a lot of scientists are working to make models that aren't just fun. But building a working human heart requires much more than the right kind of muscle cells. Called bioprinters, these machines use human cells as ink. Should we even be printing human organs (not everyone thinks so)? Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Some public libraries even have them, including the the first 3d printed blood vessel was made in 2009 and the first such human jaw was implanted in the netherlands in 2012. ► subscribe for more tech & culture. Traditional 3d printer technology relies on the process of additive manufacturing.

3d Printing Human Organs 3d Printed Bone Tissue New 3d Printing Skin Tissue Revolutionary 3d Printed Ear Blogmech . Cornell University's Hod Lipson Explains How A 3D Printer Producing Silicone Ears Could Lead To A Machine That Will One Day Print Functional Body Parts.

How 3d Printing Is Changing Health And Medicine. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. ► subscribe for more tech & culture. The idea of bioprinting human organs is no longer some far off science fiction idea. Traditional 3d printer technology relies on the process of additive manufacturing. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. The human tissue printed out so far by the. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Scientists are racing to make replacement human organs with 3d printers.

Need A New Ear Technion Opens 3d Tissue Printer For Researchers The Times Of Israel - Unlike Normal Printing, A 3D Printer Does Not Use Ink Or Toner, But Special Types Of Materials.

3d Printed Human Organs Making Future Transplant Wait Lists Shorter. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. ► subscribe for more tech & culture. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Scientists are racing to make replacement human organs with 3d printers. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. The human tissue printed out so far by the.

How Medical 3d Printing Could Solve The Shortage Of Organ Donations Youtube . Sure, 3d printers that can spit out chocolates, create shoes, handcraft cars and help astronauts sound fun and magical, but a lot of scientists are working to make models that aren't just fun.

3d Printed Organs And Body Parts Projects 3dnatives. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. ► subscribe for more tech & culture. The idea of bioprinting human organs is no longer some far off science fiction idea. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. The human tissue printed out so far by the. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Traditional 3d printer technology relies on the process of additive manufacturing. Scientists are racing to make replacement human organs with 3d printers.

Implantable 3d Printed Organs Could Be Coming Sooner Than You Think Techcrunch , About 0% Of These Are Medical Science.

3d Printing Human Organs 3d Printed Bone Tissue New 3d Printing Skin Tissue Revolutionary 3d Printed Ear Blogmech. The idea of bioprinting human organs is no longer some far off science fiction idea. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. The human tissue printed out so far by the. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Scientists are racing to make replacement human organs with 3d printers. ► subscribe for more tech & culture. Traditional 3d printer technology relies on the process of additive manufacturing. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year.

How Scientists Are 3d Bio Printing Human Organs Youtube : The Idea Of Bioprinting Human Organs Is No Longer Some Far Off Science Fiction Idea.

How To 3d Print Human Tissue The Startup 3d Printing Human Organs To Save Lives Bioprinting World. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Scientists are racing to make replacement human organs with 3d printers. Traditional 3d printer technology relies on the process of additive manufacturing. The idea of bioprinting human organs is no longer some far off science fiction idea. The human tissue printed out so far by the. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. ► subscribe for more tech & culture. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind.

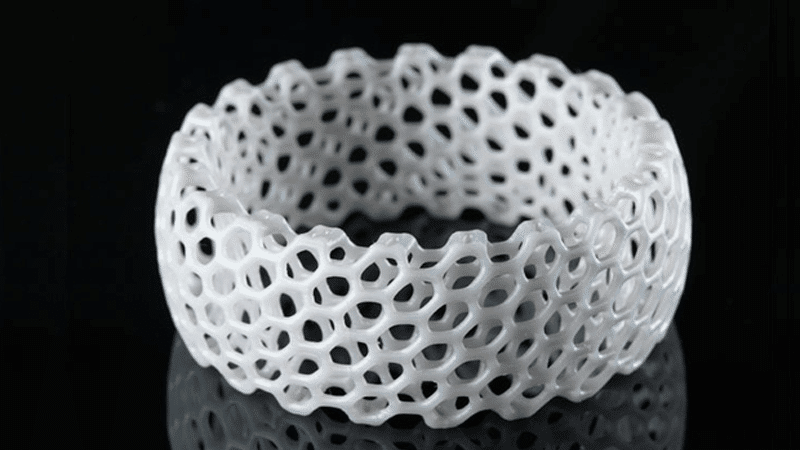

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcttw1mktbru3so8vmxafnzsdcs248vuzw7wja Usqp Cau . To Print An Ear, A Bioprinter Simultaneously Builds A Polymer Scaffold, Like The One Shown Here, And Covers It In Cells That Form Cartilage.

Mimicking The Growth Of Human Organs Through 3d Bio Printing Adam Feinberg Youtube. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. ► subscribe for more tech & culture. Scientists are racing to make replacement human organs with 3d printers. Traditional 3d printer technology relies on the process of additive manufacturing. The human tissue printed out so far by the. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. The idea of bioprinting human organs is no longer some far off science fiction idea. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of.

The Science Fiction World Of 3d Printed Organs - Traditional 3D Printer Technology Relies On The Process Of Additive Manufacturing.

Silicon Valley Startup 3d Printing Human Organs To Save Lives. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. The idea of bioprinting human organs is no longer some far off science fiction idea. ► subscribe for more tech & culture. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Traditional 3d printer technology relies on the process of additive manufacturing. Scientists are racing to make replacement human organs with 3d printers. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. The human tissue printed out so far by the.

Mimicking The Growth Of Human Organs Through 3d Bio Printing Adam Feinberg Youtube , Contents Hide 3 Bio 3D Printing Of Human Body Organs 4 We Are Now Testing Items On A Material That Responds Precisely Like Human Skin Researchers Are Dashing To Make Supplanting Human Organs With Bio 3D Printers.

3d Printers Will Soon Be Used To Print Human Organs. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. The idea of bioprinting human organs is no longer some far off science fiction idea. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. Scientists are racing to make replacement human organs with 3d printers. Traditional 3d printer technology relies on the process of additive manufacturing. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year. The human tissue printed out so far by the. ► subscribe for more tech & culture. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade.

3d Printing Technique That Can Help Replicate Human Organs Developed Science News India Tv - 3D Printing Is A Type Of Additive Manufacturing Technique Wherein, Unlike Subtractive Manufacturing, The Material Is Added Layer By Layer.

3d Printing Human Organs But Where S The Money For It Technology The Guardian. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. The idea of bioprinting human organs is no longer some far off science fiction idea. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. Traditional 3d printer technology relies on the process of additive manufacturing. Scientists are racing to make replacement human organs with 3d printers. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. The human tissue printed out so far by the. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. ► subscribe for more tech & culture. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year.

The Science Fiction World Of 3d Printed Organs - These Materials Add A New, Precise Layer To The Design With Most Experts Predict That Some Printed Artificial Organs Will Make Perfect Replacements.

11 Leading 3d Bioprinting Companies By Top 3d Shop Medium. These materials add a new, precise layer to the design with most experts predict that some printed artificial organs will make perfect replacements. ► subscribe for more tech & culture. Us researchers at cornell university have engineered an ear made of silicone using a 3d printer, which they hope will one day be capable of. 3d bioprinting, the process of using bioink composed of tissue or human cells, has come a long way over the last decade. The idea of bioprinting human organs is no longer some far off science fiction idea. Scientists are racing to make replacement human organs with 3d printers. Bioengineers at rice university created entangled cardiovascular networks similar to the body's natural passageways. Traditional 3d printer technology relies on the process of additive manufacturing. This process involves gradual addition of materials from the printer that while this is encouraging, the main challenge in the industry was printing out functional human organs. Organ printing utilizes techniques similar to conventional 3d printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3d object is produced. The human tissue printed out so far by the. Unlike normal printing, a 3d printer does not use ink or toner, but special types of materials. Instead of printing layer upon layer of living cells to form a 3d structure, like a conventional 3d printer would do with plastic or metal, the bioprinter would first be used to print a biodegradable scaffold structure of the heart, a kind. Cornell university's hod lipson explains how a 3d printer producing silicone ears could lead to a machine that will one day print functional body parts. When printed using an fdm printer, the nozzle used for the printing process is heated to high temperatures to melt the plastic and create the human trials for the liver transplants could start as early as this year.