3D Printer Slicer Algorithm. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. I do work on algorithms for 3d printers from the path planning side. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: What mathematical algorithms are used to perform this type of mesh decimation/slicing? In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. The following topics are highlighted in this. Think of the slicer as a tool path generator. This is a far better documented problem in cnc machines than it is in 3d printers. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. Fdm 3d printer slicing algorithm with matlab.

3D Printer Slicer Algorithm , The Slicer Cuts Your Cad Model Into Horizontal Layers Based On The Settings You Choose, And Calculates How Much Material Your Printer Will Need To Be Extrude And How Long It.

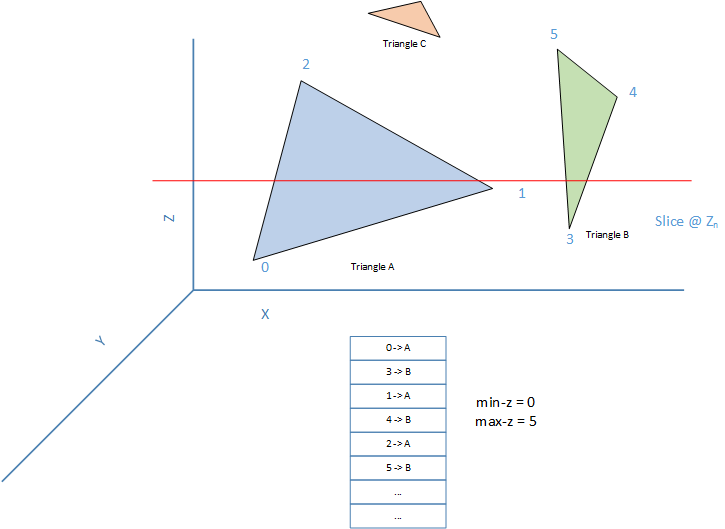

3d Printing Slicing 3d Objects Deepak Kandepet. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. This is a far better documented problem in cnc machines than it is in 3d printers. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. The following topics are highlighted in this. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. I do work on algorithms for 3d printers from the path planning side. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. Think of the slicer as a tool path generator. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. What mathematical algorithms are used to perform this type of mesh decimation/slicing? Fdm 3d printer slicing algorithm with matlab.

Congratulations, you've made it this far.

3d printing slicer software essentially acts as the middleman between the 3d model and printer. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: You've successfully setup your printer and you've gone as far as calibrating it. The amazing astroprint cloud slicer. This is a far better documented problem in cnc machines than it is in 3d printers. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. It was developed, hosted and maintained by the 3d printer company ultimaker. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. If you own a desktop 3d printer, you're almost certainly familiar with slic3r. But first you must make a choice on which slicer to use. Stl to gcode, x3g online generator. For each support created, the algorithm will try to avoid as much as possible the. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Think of the slicer as a tool path generator. Looking for a slicer for formlabs sla 3d printers? The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. Congratulations, you've made it this far. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. Best resin 3d slicers for printing dlp, sla or lcd 3d printed parts. Evaluation of dimensional accuracy and material properties of the makerbot 3d desktop printer3d printer show full abstract the experimental result shows that the proposed algorithm can effectively reduce. Various settings including print, material, printer can be tweaked depending on your needs, with prusa printer owners overall finding the resin 3d slicer very useful. Slicing the 3d model into different parts will make it easier for the 3d printer to print the parts. As you may know, a slicer is a piece of 3d printing software that takes a digitized 3d model and converts it into printing instructions that your printer can then use to turn the model into a physical object. What mathematical algorithms are used to perform this type of mesh decimation/slicing? Fdm 3d printer slicing algorithm with matlab. In essence, the slicer takes the cad model and cuts it into layers. Even if the name doesn't ring a bell, there's an excellent chance that a the company wanted to offer a slicer optimized for their line of 3d printers, and being big proponents of open source, it made sense they would lean. Lychee slicer 3 provides a new powerful support system, which includes a cage mode natively.

Buy Creality Cr X Pro 3d Printe Dual Colors 3d Printing Creality3d Store Official Store For Creality 3d Printers And Accessories - The Slicer, Also Called Slicing Software, Is Computer Software Used In The Majority Of 3D Printing Processes For The Conversion Of A 3D Object Model To Specific Instructions For The Printer.

2020 Best 3d Printer Slicer Software Fall Update All3dp. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. This is a far better documented problem in cnc machines than it is in 3d printers. I do work on algorithms for 3d printers from the path planning side. Fdm 3d printer slicing algorithm with matlab. Think of the slicer as a tool path generator. The following topics are highlighted in this. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. What mathematical algorithms are used to perform this type of mesh decimation/slicing?

Formware 3d Slicing Speed Gpu And Cpu Slicing , This Tutorial Demonstrates How To Prepare Data For 3D Printing Using The Open Source Software 3D Slicer.

Scafslicr A Matlab Based Slicing Algorithm To Enable 3d Printing Of Tissue Engineering Scaffolds With Heterogeneous Porous Microarchitecture. I do work on algorithms for 3d printers from the path planning side. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. What mathematical algorithms are used to perform this type of mesh decimation/slicing? It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. The following topics are highlighted in this. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern.

Formware 3d Slicing Speed Gpu And Cpu Slicing . Slice your 3d models for your 3d printer using slic3r or cura on the cloud.

Buy Creality Cr X Pro 3d Printe Dual Colors 3d Printing Creality3d Store Official Store For Creality 3d Printers And Accessories. The following topics are highlighted in this. Think of the slicer as a tool path generator. Fdm 3d printer slicing algorithm with matlab. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: I do work on algorithms for 3d printers from the path planning side. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. This is a far better documented problem in cnc machines than it is in 3d printers. What mathematical algorithms are used to perform this type of mesh decimation/slicing?

3d Slicer Settings For Beginners 8 Things You Need To Know : It Was Developed, Hosted And Maintained By The 3D Printer Company Ultimaker.

Online Stl Slicer Gcode X3g Generator Astroprint. What mathematical algorithms are used to perform this type of mesh decimation/slicing? Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. The following topics are highlighted in this. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. Think of the slicer as a tool path generator. This is a far better documented problem in cnc machines than it is in 3d printers. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. I do work on algorithms for 3d printers from the path planning side. Fdm 3d printer slicing algorithm with matlab. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used:

Scafslicr A Matlab Based Slicing Algorithm To Enable 3d Printing Of Tissue Engineering Scaffolds With Heterogeneous Porous Microarchitecture . Now You Are Ready To Start Printing.

Smooth Operation Eliminates Fdm Stair Stepping In University Of Hamburg Study 3d Printing Industry. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: I do work on algorithms for 3d printers from the path planning side. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. Fdm 3d printer slicing algorithm with matlab. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. Think of the slicer as a tool path generator. The following topics are highlighted in this. This is a far better documented problem in cnc machines than it is in 3d printers. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. What mathematical algorithms are used to perform this type of mesh decimation/slicing?

Craftunique Craftware The 3d Printer Slicer Software . This Is A Far Better Documented Problem In Cnc Machines Than It Is In 3D Printers.

From 3d Models To 3d Prints An Overview Of The Processing Pipeline Livesu 2017 Computer Graphics Forum Wiley Online Library. The following topics are highlighted in this. This is a far better documented problem in cnc machines than it is in 3d printers. I do work on algorithms for 3d printers from the path planning side. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. Think of the slicer as a tool path generator. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: Fdm 3d printer slicing algorithm with matlab. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. What mathematical algorithms are used to perform this type of mesh decimation/slicing?

2020 Best 3d Printer Slicer Software Fall Update All3dp . A Combo Of Manufacturers Recommended Settings And Our Own Algorithms Give Great Results.

Sensors Free Full Text Fused Deposition Material 3d Printing Procedure And Algorithm Avoiding Use Of Any Supports Html. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. This is a far better documented problem in cnc machines than it is in 3d printers. What mathematical algorithms are used to perform this type of mesh decimation/slicing? For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. Think of the slicer as a tool path generator. The following topics are highlighted in this. Fdm 3d printer slicing algorithm with matlab. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. I do work on algorithms for 3d printers from the path planning side.

Craftunique Craftware The 3d Printer Slicer Software , The Slicer Cuts Your Cad Model Into Horizontal Layers Based On The Settings You Choose, And Calculates How Much Material Your Printer Will Need To Be Extrude And How Long It.

Craftunique Craftware The 3d Printer Slicer Software. The following topics are highlighted in this. Fdm 3d printer slicing algorithm with matlab. I do work on algorithms for 3d printers from the path planning side. What mathematical algorithms are used to perform this type of mesh decimation/slicing? The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: This is a far better documented problem in cnc machines than it is in 3d printers. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. Think of the slicer as a tool path generator. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer.

Sensors Free Full Text Fused Deposition Material 3d Printing Procedure And Algorithm Avoiding Use Of Any Supports Html , Fdm 3D Printer Slicing Algorithm With Matlab.

Advanced Design For Additive Manufacturing 3d Slicing And 2d Path Planning Intechopen. This is a far better documented problem in cnc machines than it is in 3d printers. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. I do work on algorithms for 3d printers from the path planning side. Think of the slicer as a tool path generator. For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. What mathematical algorithms are used to perform this type of mesh decimation/slicing? Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: Fdm 3d printer slicing algorithm with matlab. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. The following topics are highlighted in this. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. 3d printing slicer software essentially acts as the middleman between the 3d model and printer.

Slicer An Idea Per Day : It Was Developed, Hosted And Maintained By The 3D Printer Company Ultimaker.

Scafslicr A Matlab Based Slicing Algorithm To Enable 3d Printing Of Tissue Engineering Scaffolds With Heterogeneous Porous Microarchitecture. The slicer cuts your cad model into horizontal layers based on the settings you choose, and calculates how much material your printer will need to be extrude and how long it. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. This tutorial demonstrates how to prepare data for 3d printing using the open source software 3d slicer. 3d printing slicer software essentially acts as the middleman between the 3d model and printer. What mathematical algorithms are used to perform this type of mesh decimation/slicing? For those who don't know, a 3d printing slicer prepares the selected according to the manufacturer, the slicer utilizes an algorithm that generates the best possible toolpath for the 3d printer. Think of the slicer as a tool path generator. Some for deciding on how the part is shaped, how to move along that shape, what temperature to make different parts of the path, etc. A slicer is 3d printing software that converts digital 3d models into printing instructions for your 3d printer to create an object. It is going to be a different process for every kind of hardware / there are a lot of different algorithms used: This is a far better documented problem in cnc machines than it is in 3d printers. Fdm 3d printer slicing algorithm with matlab. In this guide, we'll take a look at how slicers work, identify the most important features for us to replicate, and build a complete slicer that's to generate these structures, the slicer follows a pretty simple pattern. The following topics are highlighted in this. I do work on algorithms for 3d printers from the path planning side.