3D Printer What Is Retraction. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. To keep all3dp free and. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. When your printer does not retract enough, visible oozing will occur as the nozzle travels. Molten plastic is then layered to produce a model. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Editorial content, on principle, can not be bought or influenced. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Too little and you still get the effects above. There are a few adjustments to the. All3dp is an editorially independent publication. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres.

3D Printer What Is Retraction : Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

Missing Small Sections Of Layers After A Retraction 3d Printing Stack Exchange. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Editorial content, on principle, can not be bought or influenced. There are a few adjustments to the. Molten plastic is then layered to produce a model. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Too little and you still get the effects above. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. When your printer does not retract enough, visible oozing will occur as the nozzle travels. To keep all3dp free and. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. All3dp is an editorially independent publication. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement.

If the filament distance is too high, for example, the nozzle may clog.

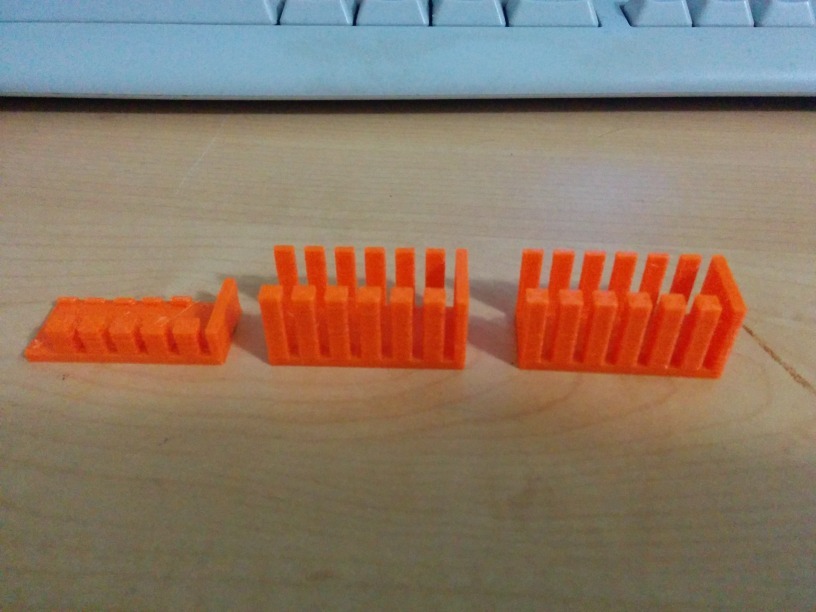

3d printing is an exciting new technology that is extremely applicable to fpv drone racing. 3d printing is a revolutionary technology that have created a buzz recently because of their ingenious concept that has been utilised in their invention, and the huge potential to impact the current manufacturing process. Too much retraction results in little gaps, or even globbing due to air pockets. I have read about the retraction settings and tried another thing is, the printer seems to be leaving gaps between some walls leaving a hole in between the two faces of a print. However, understanding what causes oozing/stringing on your prints doesn't have to be that complicated. If your printer is not set. But most printers will designed to use only one type of material. 3d printers feature retraction to prevent unwanted filament from leaking or oozing out the nozzle. In general, the more this determines how fast the filament is retracted from the nozzle. Watch this interesting video which shows how a 3d printer performs. During 3d printing, when the extruder moves to a different location, it must continue to stop or start extruding. Too little and you still get the effects above. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. 3d printing is an exciting new technology that is extremely applicable to fpv drone racing. Sla, dlp, binder jetting, and the like should not have stringing issues. Print trump smile hollow with anet et4 pro 3d printer. It relieves the pressure from the back of the filament so that it will not ooze during movement. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Retraction, temperature, and movement for fmd or fff prints. It will look terrible at first, but this will be your baseline that you compare other prints to. We provide the simplify3d factory files so adjusting the retraction value according to needs of your printer is fairly easy. 3d printers are used to make three dimensional objects and entities by printing. Learn how to 3d print. The most important retraction setting is the retraction distance. Things tagged with 'retraction' (198 things). The head must move between each of the towers at each layer. 1934 retraction test 3d models. Every day new 3d models from all over the world. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. I have run into a problem with my duplicator i3 using simplify3d. Download files and build them with your 3d printer, laser cutter, or cnc.

Retraction Blobs How To Minimize Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts , I Have Run Into A Problem With My Duplicator I3 Using Simplify3D.

Splinetravel Hackaday Io. Editorial content, on principle, can not be bought or influenced. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. There are a few adjustments to the. Too little and you still get the effects above. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Molten plastic is then layered to produce a model. All3dp is an editorially independent publication. To keep all3dp free and. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. When your printer does not retract enough, visible oozing will occur as the nozzle travels.

Splinetravel Hackaday Io , What 3D Printing Methods Are There?

What To Try Next To Reduce Stringing Assembly And First Prints Troubleshooting Prusa3d Forum. Molten plastic is then layered to produce a model. When your printer does not retract enough, visible oozing will occur as the nozzle travels. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Editorial content, on principle, can not be bought or influenced. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. All3dp is an editorially independent publication. Too little and you still get the effects above. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings.

How To Deal With 3d Printer Filament Grinding Tianse . It relieves the pressure from the back of the filament so that it will not ooze during movement.

Cel Robox S Unique Solution To The Retraction Problem The Needle Valve Fabbaloo. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. To keep all3dp free and. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. When your printer does not retract enough, visible oozing will occur as the nozzle travels. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Molten plastic is then layered to produce a model. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Too little and you still get the effects above. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. Editorial content, on principle, can not be bought or influenced. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. All3dp is an editorially independent publication. There are a few adjustments to the. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum.

How To Easily Calibrate Retraction In 3d Printers - Vat Polymerization Technologies Powder Bed Fusion.

What Is Retraction In A 3d Slicing Software Flashforge. There are a few adjustments to the. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Too little and you still get the effects above. Editorial content, on principle, can not be bought or influenced. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. All3dp is an editorially independent publication. To keep all3dp free and. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. Molten plastic is then layered to produce a model. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. When your printer does not retract enough, visible oozing will occur as the nozzle travels.

Tuning Your 3d Printer For Retraction Vision Miner , Too Little And You Still Get The Effects Above.

Retraction How It Works In 3d Printing Monroe. All3dp is an editorially independent publication. Molten plastic is then layered to produce a model. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. There are a few adjustments to the. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Too little and you still get the effects above. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. When your printer does not retract enough, visible oozing will occur as the nozzle travels. Editorial content, on principle, can not be bought or influenced. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. To keep all3dp free and. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement.

Clog In Heat Break When Retraction Enabled Page 1 Help Repair Maintenance Soliforum 3d Printing Community : 3D Printing Is An Exciting New Technology That Is Extremely Applicable To Fpv Drone Racing.

Retraction How It Works In 3d Printing Monroe. All3dp is an editorially independent publication. Molten plastic is then layered to produce a model. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Too little and you still get the effects above. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Editorial content, on principle, can not be bought or influenced. There are a few adjustments to the. When your printer does not retract enough, visible oozing will occur as the nozzle travels. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. To keep all3dp free and. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release , There Are A Few Adjustments To The.

Stop The Stringing With Retraction 3d Printing 101 Youtube. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. There are a few adjustments to the. Molten plastic is then layered to produce a model. All3dp is an editorially independent publication. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. When your printer does not retract enough, visible oozing will occur as the nozzle travels. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Too little and you still get the effects above. Editorial content, on principle, can not be bought or influenced. To keep all3dp free and. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release , Things Tagged With 'rEtraction' (198 Things).

7 Key 3d Printing Slicer Settings You Need To Know. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. There are a few adjustments to the. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. When your printer does not retract enough, visible oozing will occur as the nozzle travels. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. To keep all3dp free and. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Molten plastic is then layered to produce a model. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Too little and you still get the effects above.

Some Musings On Retracts Sublime Layers , If You Have An Fdm Or Fff 3D Printer And Are Having Issues With Stringing Please Continue Reading To Get An Understanding Of Why It Happens And How Best To.

Good Retraction Is Key Of High Quality Printing In Reprap 3d Printer Freedom World Peace In Unity. All3dp is an editorially independent publication. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. To keep all3dp free and. When your printer does not retract enough, visible oozing will occur as the nozzle travels. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Too little and you still get the effects above. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. Molten plastic is then layered to produce a model. Editorial content, on principle, can not be bought or influenced. There are a few adjustments to the.

Stringing Or Oozing . The Most Important Retraction Setting Is The Retraction Distance.

Retraction Just Say No To Oozing Matterhackers. Molten plastic is then layered to produce a model. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect get it 3d printed. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Too little and you still get the effects above. All3dp is an editorially independent publication. When your printer does not retract enough, visible oozing will occur as the nozzle travels. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. There are a few adjustments to the. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. To keep all3dp free and. How does retraction work and when should of course, eliminating stringing isn't as simple as turning on retraction in your 3d printer and leaving it be. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Editorial content, on principle, can not be bought or influenced.