3D Printer Won't Stick To Bed. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. A way to further slow down the cooling process is to print inside an enclosure. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Every printer has a different procedure for print platform leveling. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. The main reason is that many 3d materials have a tendency to shrink when cooled. Simplify3d already includes a useful bed leveling wizard that you guide you through the. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Some 3d printers come with detachable enclosures. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. If yours doesn't, then you can buy one, such as this.

3D Printer Won't Stick To Bed , The Bed Has Kapton Tape On Glass As Specified In The Assembly Instructions.

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. A way to further slow down the cooling process is to print inside an enclosure. Some 3d printers come with detachable enclosures. The main reason is that many 3d materials have a tendency to shrink when cooled. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. Simplify3d already includes a useful bed leveling wizard that you guide you through the. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. Every printer has a different procedure for print platform leveling. If yours doesn't, then you can buy one, such as this. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly.

The printer works fine for small print but anything bigger than 50mm z,y, or z it won't stick.

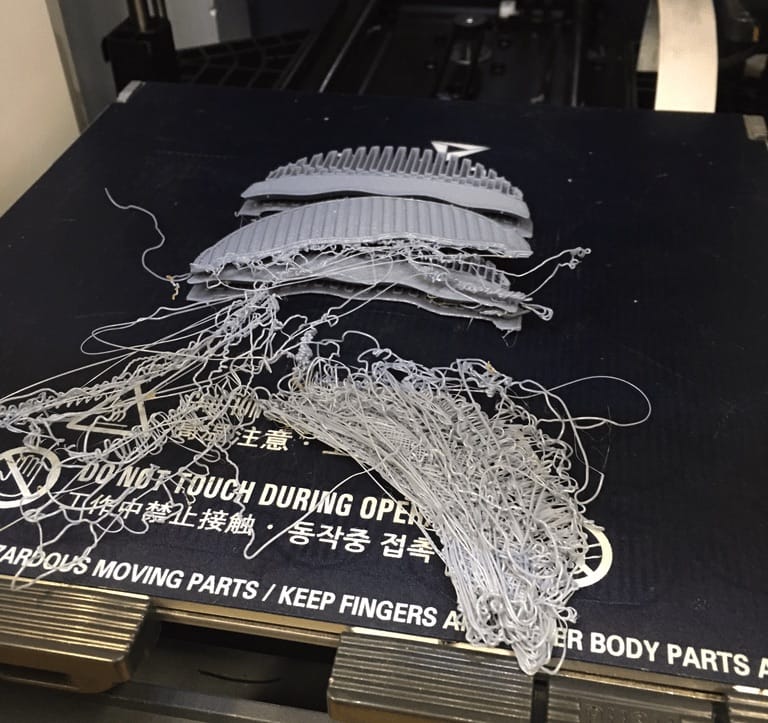

When i start to print, the printing process starts, some pla may (or may not) stick to the bed but then it is dragged off the bed and ormerod forum is a goldmine! Despite best efforts, the hot ends of 3d printers can occasionally accumulate bits of molten plastic which can sometimes end up deposited on the mark suspects that maybe the shape of the nozzle has an effect. Welcome back to think making!!! Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. Robo 3d printer r1 with heated bed. Take a look at modfab australia's guide to troubleshooting to avoid this issue. Simplify3d already includes a useful bed leveling wizard that you guide you through the. The main reason is that many 3d materials have a tendency to shrink when cooled. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. Imho, using two motors to lift the x axis is just plain bad design. Print is stuck to the bed with no warp! In fact, they need it quite often. If you are new to 3d printing, visit here first and get educated. Are you using masking tape, hairspray, or a glue stick? If a print does not stick to the build plate properly, then it could move during it is important to point out though that not all materials require a bed adhesive to stick to the build plate. Any and all help is greatly. We printed a benchy and the vase on the sd card and they both printed amazingly. In the case of heated build plates. I would suggest running a mild preheat to your bed when. A lot of the cases of pla prints not sticking comes down to preparation. I went back to using plain blue i have only experienced pla super sticking if the print bed is allowed to cool too much. The best community for a 3d printer! Abs not sticking to your print bed? You'll likely see more than a fair share controlling ambient temps also helps and there are articles about people enclosing their 3d printers to stabilize the temperatures inside the printing. I have tried 2 different types of (long lasting) hairspray, and. In this case you will see part of the model still sticking to build plate. Skewed prints won't fit together properly, gears won't mesh right, threaded parts may not work, etc. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. Sticking too well to painters tape. There are plastic mats that you stick to the bed of your 3d printer (they work on heated beds) that seemed to have. One of the ways of fixing this problem is to first have a clean base and/or use a good 3d spray, but the sure way to get good adhesion is to raise the bed till the nozzle is hitting it, but not scraping it, then just lower the bed after.

Petg Not Sticking To Pei Bed How Do I Print This Printing Help Prusa3d Forum : Are You Using Masking Tape, Hairspray, Or A Glue Stick?

How To Persistent 3d Print Failure Here S What To Look For Fabbaloo. If yours doesn't, then you can buy one, such as this. Some 3d printers come with detachable enclosures. A way to further slow down the cooling process is to print inside an enclosure. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. Every printer has a different procedure for print platform leveling. The main reason is that many 3d materials have a tendency to shrink when cooled. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. Simplify3d already includes a useful bed leveling wizard that you guide you through the.

9 Sure Fire Ways To Stop 3d Prints Moving While Printing 3dprinterly . When Printing Pieces With Large Flat Surfaces That Are Siting Flush With The Bed, It's Next To Impossible To Tear It Off At The End.

Better 3d Printing Through Magnets Hackaday. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. Simplify3d already includes a useful bed leveling wizard that you guide you through the. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. A way to further slow down the cooling process is to print inside an enclosure. Some 3d printers come with detachable enclosures. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes.

Skirt Consistently Not Sticking To Bed Others Archive Prusa3d Forum : So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes.

How To Deal With A 3d Print That Is Stuck To The Bed. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. Simplify3d already includes a useful bed leveling wizard that you guide you through the. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. If yours doesn't, then you can buy one, such as this. The main reason is that many 3d materials have a tendency to shrink when cooled. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: A way to further slow down the cooling process is to print inside an enclosure. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Every printer has a different procedure for print platform leveling. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. Some 3d printers come with detachable enclosures. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion.

Amazon Com Buildtak 3d Printing Build Surface 8 X 10 Rectangle Black Pack Of 3 Industrial Scientific - I Am Trying To Print T.

3d Printing Problems And Solutions Fixes You Need To Know. Some 3d printers come with detachable enclosures. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. If yours doesn't, then you can buy one, such as this. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: A way to further slow down the cooling process is to print inside an enclosure. Every printer has a different procedure for print platform leveling. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. The main reason is that many 3d materials have a tendency to shrink when cooled. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. Simplify3d already includes a useful bed leveling wizard that you guide you through the.

How To Persistent 3d Print Failure Here S What To Look For Fabbaloo : I Think The Real Difference That I Did Was I Calibrated The Printer At The Temperature I Want To Print (Hot) And Make Some Kind Of Enclosure For The Printer.

Heat Beds In 3d Printing Advantages And Equipment Boots Industries. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Every printer has a different procedure for print platform leveling. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. Simplify3d already includes a useful bed leveling wizard that you guide you through the. The main reason is that many 3d materials have a tendency to shrink when cooled. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. A way to further slow down the cooling process is to print inside an enclosure. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. If yours doesn't, then you can buy one, such as this. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: Some 3d printers come with detachable enclosures.

More Won T Stick Assembly And First Prints Troubleshooting Prusa3d Forum : Either An Edge Will Be Disfigured Or The Nozzle Will Drag The Filament Across The Bed Because The I'vE Gotten The Best Result With Using The Original Bed At 0 Temp With Glue But For The Most Part Pla Isn't Sticking.

What Masking Tape Is Best To Print Pla And Abs On. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. Some 3d printers come with detachable enclosures. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: Simplify3d already includes a useful bed leveling wizard that you guide you through the. If yours doesn't, then you can buy one, such as this. The main reason is that many 3d materials have a tendency to shrink when cooled. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. A way to further slow down the cooling process is to print inside an enclosure. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. Every printer has a different procedure for print platform leveling.

Amazon Com 3d Printing Build Surface 3d Printer Heat Bed Platform Sticker Sheet 12 X 12 Square With Premium Adhesive For Cr 10 Cr 10s 3d Printers 310x310mm Pack Of 4 Office Products . There Are Several Methods To Prep Your Printing Bed For Pla.

Troubleshooting An Abs Print That Won T Stick. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. A way to further slow down the cooling process is to print inside an enclosure. Simplify3d already includes a useful bed leveling wizard that you guide you through the. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Some 3d printers come with detachable enclosures. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. If yours doesn't, then you can buy one, such as this. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. The main reason is that many 3d materials have a tendency to shrink when cooled. Every printer has a different procedure for print platform leveling.

Amazon Com Buildtak 3d Printing Build Surface 8 X 10 Rectangle Black Pack Of 3 Industrial Scientific - Any And All Help Is Greatly.

How To Print On A Powder Coated Sheet Prusa Printers. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. The main reason is that many 3d materials have a tendency to shrink when cooled. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. If yours doesn't, then you can buy one, such as this. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. A way to further slow down the cooling process is to print inside an enclosure. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. Simplify3d already includes a useful bed leveling wizard that you guide you through the. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Some 3d printers come with detachable enclosures. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. Every printer has a different procedure for print platform leveling. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed.

Avoiding The Dramas Associated With Pla Prints Not Sticking , Follow Along To Learn The Secrets To Consistent, Successful Adhesion.

3 Most Common 3d Printer Errors And Their Fixes. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. Some 3d printers come with detachable enclosures. Every printer has a different procedure for print platform leveling. The main reason is that many 3d materials have a tendency to shrink when cooled. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: Simplify3d already includes a useful bed leveling wizard that you guide you through the. A way to further slow down the cooling process is to print inside an enclosure. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. If yours doesn't, then you can buy one, such as this.

Kapton Heat Bed Boots Industries : It's Possible That Sometimes Your 3D Prints Will Need Help Sticking To The Bed.

How To Succeed When 3d Printing With Pla Filament Matterhackers. Some 3d printers come with detachable enclosures. The main reason is that many 3d materials have a tendency to shrink when cooled. So i have cleaned the bed and tried making the first layer a little thicker and it helped a little as it is sometimes sticking now, but it still is coming up or just not sticking to the glass sometimes. If yours doesn't, then you can buy one, such as this. I'm using the monoprice maker select 3d (might be v2) printer (iiip) (i think it's a prusa i3 clone), cura 3.2.1, and hatchbox pla. If your printer has an adjustable bed and you're achieving a perfect first layer requires a level print bed. A way to further slow down the cooling process is to print inside an enclosure. So i just finished installing and leveling a borosilicate glass bed on my 3d printer (i was previously edit: Some like lulzbots make use of reliable auto leveling if the nozzle is too high then the filament won't stick to the platform, too low and the nozzle will actually start to scrape the print off. When the pla touches the bed it doesn't stick, and when it prints it takes a few seconds to stick and messes up. Some 3d printer filaments require a heated print bed in order get 3d printed parts to stick to the bed properly. How strongly the first layer sticks to the print bed is directly proportional to the surface of contact between them. Depending on your settings and the material you are printing with, you may run into some problems with bed adhesion. Simplify3d already includes a useful bed leveling wizard that you guide you through the. Every printer has a different procedure for print platform leveling.