3D Printer Z Height Issues. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. If you realise this is the problem, stop the print immediately: If i need to make a small adjustment i can dial it up or down a touch without issue. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. Having trouble getting your prints to stick? I have searched for a solution to this problem without success. I used this wave spring to minimize the z height change. If i chose 2d or 3d it makes no real difference. Are your 3d printed parts not fitting together properly? Here are the print specs This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. Try using z offset to adjust where your 3d printer starts printing. Want to print on top of an existing object?

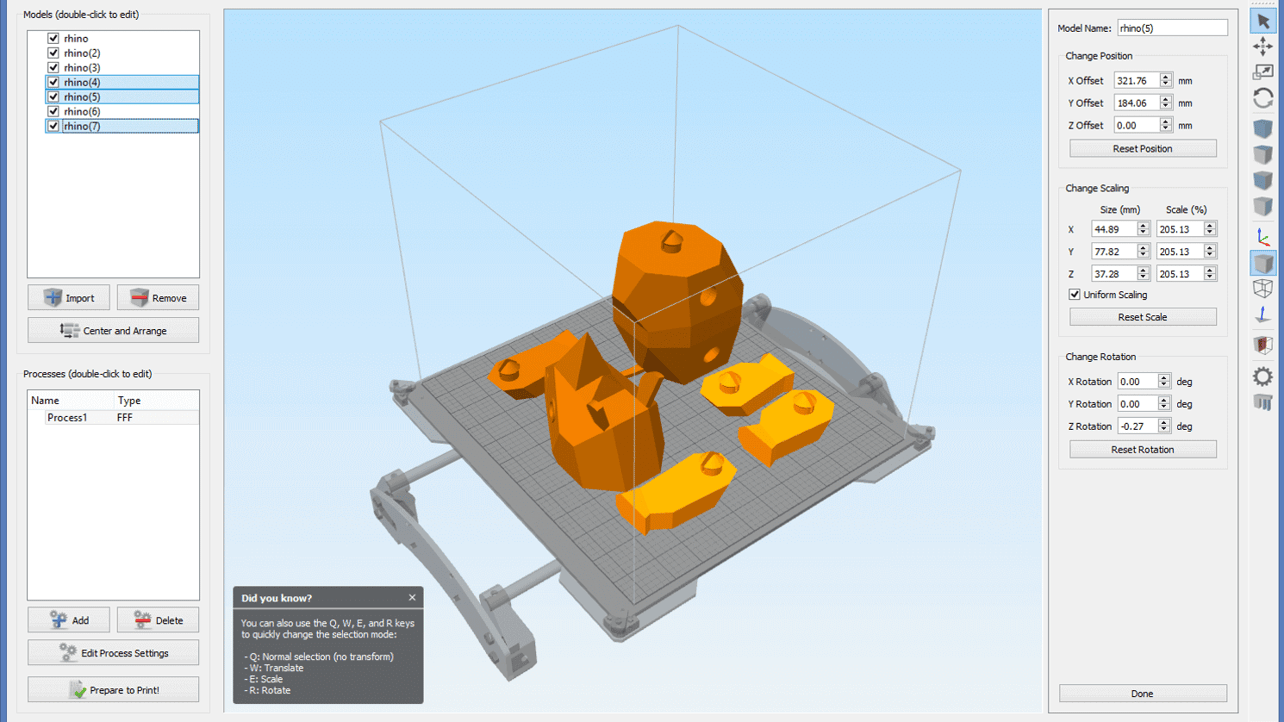

3D Printer Z Height Issues : Here Are The Print Specs

Fdm 3d Printing Common Problems And How To Solve Them By Bitfab Wikifactory. Having trouble getting your prints to stick? If you realise this is the problem, stop the print immediately: Are your 3d printed parts not fitting together properly? This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. If i chose 2d or 3d it makes no real difference. Try using z offset to adjust where your 3d printer starts printing. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. If i need to make a small adjustment i can dial it up or down a touch without issue. Here are the print specs Want to print on top of an existing object? I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). I have searched for a solution to this problem without success. I used this wave spring to minimize the z height change. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm.

If you typically have issues with moisture in your filament, you can read our tips and comments on filament storage to determine if a dry box will be beneficial.

Exposure time is the amount of time that the light source will expose each layer during printing. Printed in pla and polymaker polysupport on my e3d big box dual titan hybrid. Before that i tried several different things to mitigate. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. The dlp printer is in an eternal battle where, between layers, the 3d print is expected to peel away from the fep film. Then i realised that there is one possible explanation for the increased height of the print. Want to print on top of an existing object? As part of the setup and instructions i have to place set the print head at the origin in x and y then lower the head what could be causing this issue? The simulation looks ok and i am sure i have it right. It prints well but as i mentioned in previous articles i had to level for every print. The probe should trigger and the z movement should stop. Actually near the end i would just overpower the stepper motors while the skirt leveling front to back was not affected. Connect to the printer from a browser. We recommend only printing with a quality pc filament. I used this wave spring to minimize the z height change. If you realise this is the problem, stop the print immediately: Improper bed surface or settings for filament. So this worked but it was frustrating. I also have cut these before on this machine using onecnc with success, so its not the machine. You've checked the model, seen countless others make it without issue, but just raising the height of the nozzle slightly can often help, but be careful too high and it won't stick to the platform. A common issue i noticed on the sidewinder x1 is the amount of pressure the idler lever puts on the filament. When your printed object turns out to be substantially larger or smaller than your originally model digital model it could be that your printer is equipped with incorrect firmware and therefore takes to many steps on the. With the nozzle too far from. Some common calibration issues as well as common build related issues however are discussed. Recently received a robo 3d r1 (last week) and after printing a larger item i am noticing that the z height of the print is off by a few mm. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. In the worth cas the plastic can expand/react/change state inside the hotend. I wrote this tutorial to (try to) show you how to get a perfect first layer ( which. Please see the picture for reference, the top flat portion of the model is quite a bit longer than the main head portion (it was printed flat on the print bed at the same. Nozzle diameter directly relates to the layer heights that you can successfully print.

Leveling And Calibration Of The 3d Printer Base : We Have Compiled An Extensive List Of The Most Common 3D Printing Issues Along With The Software Settings That You Can Use To Solve Them.

3d Printing Concepts And 3d Printer Parts Leapfrog 3d Printers. If i need to make a small adjustment i can dial it up or down a touch without issue. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. Try using z offset to adjust where your 3d printer starts printing. I used this wave spring to minimize the z height change. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). Want to print on top of an existing object? If i chose 2d or 3d it makes no real difference. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. If you realise this is the problem, stop the print immediately: This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. Having trouble getting your prints to stick? Here are the print specs 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Are your 3d printed parts not fitting together properly? I have searched for a solution to this problem without success.

Troubleshooting Guide To Common 3d Printing Problems All3dp - The Print Quality For Each 3D Resin Is Also Affected By The Light Power And The Curing Or Exposure Time.

Fdm 3d Printing Common Problems And How To Solve Them By Bitfab Wikifactory. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. If i chose 2d or 3d it makes no real difference. If i need to make a small adjustment i can dial it up or down a touch without issue. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If you realise this is the problem, stop the print immediately: Are your 3d printed parts not fitting together properly? I have searched for a solution to this problem without success. Having trouble getting your prints to stick? When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

Testing Your 3d Printer S First Layer Height Calibration Blue Paper Technology Llc - If i need to make a small adjustment i can dial it up or down a touch without issue.

Why Are There Lines On The Side Of Your 3d Print The 3d Bros. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. If you realise this is the problem, stop the print immediately: Want to print on top of an existing object? Try using z offset to adjust where your 3d printer starts printing. Here are the print specs If i need to make a small adjustment i can dial it up or down a touch without issue. Having trouble getting your prints to stick? When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. I used this wave spring to minimize the z height change. Are your 3d printed parts not fitting together properly? I have searched for a solution to this problem without success. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). If i chose 2d or 3d it makes no real difference.

How To Print The Perfect First Layer On Your 3d Printer Youtube , If The Probe Needs To Be Deployed Before Use (E.g.

Labists 3d Printer Trouble Shooting X1. Having trouble getting your prints to stick? Here are the print specs I used this wave spring to minimize the z height change. Want to print on top of an existing object? If i need to make a small adjustment i can dial it up or down a touch without issue. Are your 3d printed parts not fitting together properly? Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Try using z offset to adjust where your 3d printer starts printing. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). If you realise this is the problem, stop the print immediately: I have searched for a solution to this problem without success. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If i chose 2d or 3d it makes no real difference.

3 Most Common 3d Printer Errors And Their Fixes : As Part Of The Setup And Instructions I Have To Place Set The Print Head At The Origin In X And Y Then Lower The Head What Could Be Causing This Issue?

Prusa Knowledge Base Bed Level Correction. Are your 3d printed parts not fitting together properly? I have searched for a solution to this problem without success. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. Try using z offset to adjust where your 3d printer starts printing. If you realise this is the problem, stop the print immediately: Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). Here are the print specs If i need to make a small adjustment i can dial it up or down a touch without issue. Having trouble getting your prints to stick? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Want to print on top of an existing object? If i chose 2d or 3d it makes no real difference. I used this wave spring to minimize the z height change.

Irregular And Uneven Ridges And Striations On Z Axis Throughout Print 3d Printing 3d Printers Talk Manufacturing 3d Hubs : Different Sla/Dlp/Lcd 3D Printers Have Different Cure Times For Resins.

Perfecting The First Layer. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). If you realise this is the problem, stop the print immediately: Having trouble getting your prints to stick? Here are the print specs I used this wave spring to minimize the z height change. Try using z offset to adjust where your 3d printer starts printing. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If i need to make a small adjustment i can dial it up or down a touch without issue. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. Are your 3d printed parts not fitting together properly? If i chose 2d or 3d it makes no real difference. I have searched for a solution to this problem without success. Want to print on top of an existing object?

Bed Leveling As Demonstrated On An Ender 3 The Spaghetti Detective - Printed In Pla And Polymaker Polysupport On My E3D Big Box Dual Titan Hybrid.

Strange Layer Separation Issues On Ender 3 3d Printing Stack Exchange. Want to print on top of an existing object? When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Try using z offset to adjust where your 3d printer starts printing. If i chose 2d or 3d it makes no real difference. I have searched for a solution to this problem without success. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). Are your 3d printed parts not fitting together properly? Having trouble getting your prints to stick? This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If you realise this is the problem, stop the print immediately: Here are the print specs If i need to make a small adjustment i can dial it up or down a touch without issue. I used this wave spring to minimize the z height change. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm.

Z Height Incorrect On Calibration Cube 3d Printing Stack Exchange - I Have Searched For A Solution To This Problem Without Success.

3 Most Common 3d Printer Errors And Their Fixes. Want to print on top of an existing object? I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). If i need to make a small adjustment i can dial it up or down a touch without issue. Here are the print specs When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. Are your 3d printed parts not fitting together properly? Try using z offset to adjust where your 3d printer starts printing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Having trouble getting your prints to stick? I used this wave spring to minimize the z height change. If you realise this is the problem, stop the print immediately: I have searched for a solution to this problem without success. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If i chose 2d or 3d it makes no real difference.

Z Height Incorrect On Calibration Cube 3d Printing Stack Exchange , Here Are The Print Specs

Z Height Incorrect On Calibration Cube 3d Printing Stack Exchange. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. I used this wave spring to minimize the z height change. If you realise this is the problem, stop the print immediately: This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat. If i chose 2d or 3d it makes no real difference. Here are the print specs Want to print on top of an existing object? I have searched for a solution to this problem without success. Are your 3d printed parts not fitting together properly? If i need to make a small adjustment i can dial it up or down a touch without issue. When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. Try using z offset to adjust where your 3d printer starts printing. Having trouble getting your prints to stick? I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d).

Amazon Com 3d Printing Failures How To Diagnose And Repair All 3d Printing Issues 9781547202386 Aranda Sean Feeney David Books , The Dlp Printer Is In An Eternal Battle Where, Between Layers, The 3D Print Is Expected To Peel Away From The Fep Film.

Calibrating Your Z Offset Me3d Support. Overall height is only 19.10mm, which is quite a ways off, while the x/y were both around 19.98mm. Here are the print specs Try using z offset to adjust where your 3d printer starts printing. If you realise this is the problem, stop the print immediately: If i need to make a small adjustment i can dial it up or down a touch without issue. I measured (approximately) the layer thickness under a microscope and each layer was only 0.12mm or so thick which is way off from the 0.20mm specified in my slicer (simplify3d). Are your 3d printed parts not fitting together properly? When setup correctly, z height works when homing, but when a print is sent and after what looks like a successful auto bed homing, etc., the printer starts to print about 1.5 inches too high. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. I used this wave spring to minimize the z height change. If i chose 2d or 3d it makes no real difference. Want to print on top of an existing object? I have searched for a solution to this problem without success. Having trouble getting your prints to stick? This is the typical situation in which you could generate a clog in the cold end of your extruder, which is not a permanent damage, but fixing it is a somewhat.