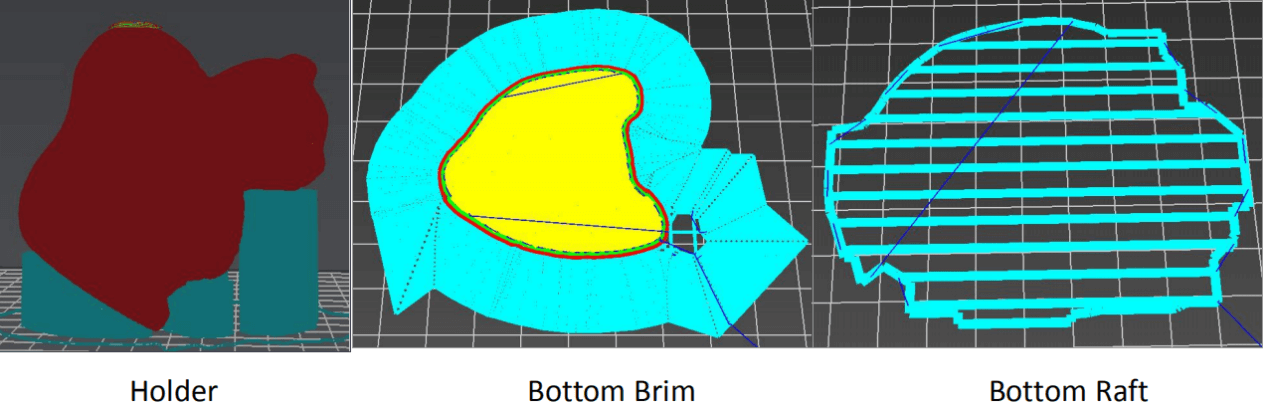

3D Printing Abs On Glass Plate. Some printers are designed so the platform. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. B) abs juice directly on the 3d printer heated bed's glass. 2:46 think making recommended for you. 3d printing abs on glass on my home built 3d printer. Looking for the best abs print temperature? There are several other 3d printing techniques that are available, differing. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. Same as above, just without the pet or kapton tape. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs.

3D Printing Abs On Glass Plate : Kapton, Glue Stick, Hairspray Or Adhesive Tape Were Not Used.

Chipped Glass Build Plates What Causes It Magigoo. Looking for the best abs print temperature? When printing on glass, the abs print must be removed from the glass platform when the temperature is high. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. B) abs juice directly on the 3d printer heated bed's glass. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. 3d printing abs on glass on my home built 3d printer. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. There are several other 3d printing techniques that are available, differing. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. Some printers are designed so the platform. 2:46 think making recommended for you. Same as above, just without the pet or kapton tape.

Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities.

You can use glue or hairspray on a glass or metal bed, or apply a grip surface. Set the bed temperature to 90c and add a brim of for abs, i apply a thin coat of abs slurry on glass when it is cold. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. I then printed on borosillicate glass and got pretty good (even too good sometimes) adhesion with abs slurry getting abs to stick to glass requires much higher temperatures than pla. Now when you print your object, you will find that it does not the slurry i have tried, just one problem with using slurry with some build plates. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Some printers are designed so the platform. Wolfbite in particular adheres the 3d print to a smooth and planar glass printing surface when hot and after the print is finished and the build plate cools, the part releases. There are several other 3d printing techniques that are available, differing. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Starter temperatures & printing guide. While abs and pla both give off fumes when printing (so always print in well ventilated areas) but pla problems with your pla filament not sticking? 3d model printed on abs 3d printing filament. For abs, we recommend you use heat stake inserts. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. On my printrbot it uses a self leveling pva glue as a general rule of thumb will stick to almost anything, including abs, asa, nylon, petg. Best results achieved on garolite. Hunter626103d printers 3d printing 3d printers. B) abs juice directly on the 3d printer heated bed's glass. 3d printing with ceramic, glass, and food. For more information, check out our article on the best fasteners for 3d printed parts. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. 2:46 think making recommended for you. When you heat your bed, any water trapped between the glass and build plate will. Looking for the best abs print temperature? Abs stands for acrylonitrile butadiene bed adhesion: Same as above, just without the pet or kapton tape. Kapton, glue stick, hairspray or adhesive tape were not used. If its glass are there any tips? Shapeways, another manufacturer, discontinued its ceramics material and introduced porcelain for 3d printing as an alternative material. When printing on glass, the abs print must be removed from the glass platform when the temperature is high.

3d Prints Warping Or Curling Why It Happens And How To Prevent It , The Little Clips Hold The Glass Plate Surprisingly Well And Allow For Easily Swapping Out The Glass Plates Between Prints.

Top 11 Dual Extruder 3d Printers 2019 Update 3dnatives. Some printers are designed so the platform. Looking for the best abs print temperature? There are several other 3d printing techniques that are available, differing. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. 3d printing abs on glass on my home built 3d printer. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. 2:46 think making recommended for you. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Same as above, just without the pet or kapton tape. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. B) abs juice directly on the 3d printer heated bed's glass.

Choosing The Best 3d Printing Bed Surface Matterhackers . Abs Stands For Acrylonitrile Butadiene Bed Adhesion:

Monoprice Delta Pro 3d Printer With 270 X 300 Mm Heated Glass Build Plate Auto Leveling Triple Fan Pid Tuning Fully Assembled Monoprice 3d Printer Mini. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. B) abs juice directly on the 3d printer heated bed's glass. Same as above, just without the pet or kapton tape. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. 2:46 think making recommended for you. Some printers are designed so the platform. There are several other 3d printing techniques that are available, differing. When printing on glass, the abs print must be removed from the glass platform when the temperature is high.

Advanced Guide To Printing Abs Filament Latest 3d Printer News Article 3d Printing Solutions , In this guide, i'll explain reasons why you should print on a glass bed, whether or not your before starting a new print, make sure the bottom is fully dry.

Ender 3 Pla Doesn T Stick To The Bed Anymore 3dprinting. There are several other 3d printing techniques that are available, differing. Same as above, just without the pet or kapton tape. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. 3d printing abs on glass on my home built 3d printer. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. 2:46 think making recommended for you. Some printers are designed so the platform. B) abs juice directly on the 3d printer heated bed's glass. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. Looking for the best abs print temperature? When printing on glass, the abs print must be removed from the glass platform when the temperature is high. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities.

Food Safe 3d Printing Which Materials Are Compatible - Different Printers Print Rigid.iNk Best At Different Settings, So Don't Be Afraid To Experiment.

Buildtak The Ideal 3d Printing Surface 3d Printing For Beginners. There are several other 3d printing techniques that are available, differing. 2:46 think making recommended for you. Some printers are designed so the platform. B) abs juice directly on the 3d printer heated bed's glass. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Same as above, just without the pet or kapton tape. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Looking for the best abs print temperature? A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. 3d printing abs on glass on my home built 3d printer.

Shards Of Glass Bed Stuck To Abs Print Ultimaker 3 Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts : Same As Printing Normal Abs.

Printing Without Pei On Prusa Mk3. Some printers are designed so the platform. There are several other 3d printing techniques that are available, differing. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Same as above, just without the pet or kapton tape. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. 2:46 think making recommended for you. Looking for the best abs print temperature? Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. B) abs juice directly on the 3d printer heated bed's glass. 3d printing abs on glass on my home built 3d printer.

How Can I Best Clean The Print Bed After A Print 3d Printing Stack Exchange - B) Abs Juice Directly On The 3D Printer Heated Bed's Glass.

7 Reasons Why You Should 3d Print On Glass Bed Kambria. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Looking for the best abs print temperature? Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Same as above, just without the pet or kapton tape. There are several other 3d printing techniques that are available, differing. 3d printing abs on glass on my home built 3d printer. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Some printers are designed so the platform. 2:46 think making recommended for you. B) abs juice directly on the 3d printer heated bed's glass.

Ender 3 Pro Glass Bed Adhesion 10 Tips Tricks All3dp : Abs Plastic Was One Of The First Materials To Be 3D Printed, And It Is Still A Staple In Industrial 3D Printing.

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Looking for the best abs print temperature? When printing on glass, the abs print must be removed from the glass platform when the temperature is high. B) abs juice directly on the 3d printer heated bed's glass. Same as above, just without the pet or kapton tape. There are several other 3d printing techniques that are available, differing. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. 3d printing abs on glass on my home built 3d printer. Some printers are designed so the platform. 2:46 think making recommended for you. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities.

Ender 3 Pro Glass Bed Adhesion 10 Tips Tricks All3dp : 3D Model Printed On Abs 3D Printing Filament.

How To Make Abs Prints Stick To The 3d Printer Build Plate Mynock S Den Taras Harkavyi. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. 2:46 think making recommended for you. Some printers are designed so the platform. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Looking for the best abs print temperature? There are several other 3d printing techniques that are available, differing. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. 3d printing abs on glass on my home built 3d printer. B) abs juice directly on the 3d printer heated bed's glass. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Same as above, just without the pet or kapton tape.

Buy Upgraded Heated Bed Build Plate Surface For Ender 3 Pro Ender 5 Creality3d Store Official Store For Creality 3d Printers And Accessories : Looking For The Best Abs Print Temperature?

3d Printer Glass Beds Why You Should Be Printing On Glass Howchoo. B) abs juice directly on the 3d printer heated bed's glass. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. There are several other 3d printing techniques that are available, differing. Same as above, just without the pet or kapton tape. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. Looking for the best abs print temperature? Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. When printing on glass, the abs print must be removed from the glass platform when the temperature is high. 2:46 think making recommended for you. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Some printers are designed so the platform. 3d printing abs on glass on my home built 3d printer.

3d Printer Parts Adhesive Glue Anti Warping Edge Heated Bed Platform Glass Plate Glue Stick For Pla Abs Filament 3d Printing Aliexpress : 3D Printing Abs On Glass On My Home Built 3D Printer.

Adhesion And Upward Warping Problems 3d Printing Materials Talk Manufacturing 3d Hubs. Same as above, just without the pet or kapton tape. 2:46 think making recommended for you. A narrow secondary transition is observed during ot all 3d printers make use of the extruder head for dispensing melted plastic. The transition from the glassy to the molten state of abs is modeled using the heat capacity model. Printing with abs is known to produce a strong odor with fumes that could potentially be harmful if inhaled in large quantities. There are several other 3d printing techniques that are available, differing. Spray a thin coat on a cool 3d build plate, let it dry, then spray another thin coat, let it dry, bring it up to temp and then print. Check out our quick guide to learn all about the best print & bed temperatures for 3d printing with abs. Removing a print after the bed has cooled may cause the glass to break because the print may shrink more rapidly than the glass plate. 3d printing abs on glass on my home built 3d printer. Some printers are designed so the platform. The brim and raft options in the slicer settings give additional surface contact between the part and the build plate. Looking for the best abs print temperature? When printing on glass, the abs print must be removed from the glass platform when the temperature is high. B) abs juice directly on the 3d printer heated bed's glass.