3D Printing Abs Plastic Properties. Abs is known for its toughness and. It is used in the bodywork of cars, appliances, and mobile phone cases. This material was one of the first plastics to be used with industrial 3d printers. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs filament is the most used home 3d printer filament after pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs filament is the most commonly used 3d printing plastics. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Discover abs plastic commonly used in 3d printing. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Commodity plastic, improved mechanical and thermal properties compared to pla. 3d printing on perforated boards will.

3D Printing Abs Plastic Properties - Abs Is Known For Its Toughness And.

Pla Plastic Material All You Need To Know In 2020 All3dp. Abs filament is the most used home 3d printer filament after pla. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. It is used in the bodywork of cars, appliances, and mobile phone cases. 3d printing on perforated boards will. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Discover abs plastic commonly used in 3d printing. Abs filament is the most commonly used 3d printing plastics. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. This material was one of the first plastics to be used with industrial 3d printers. Abs is known for its toughness and. Commodity plastic, improved mechanical and thermal properties compared to pla. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties.

3d printing on perforated boards will.

Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Commodity plastic, improved mechanical and thermal properties compared to pla. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. A 3d printed part made from abs will be less durable than. How to select the right 3d printing material. Therefore, 3d printing prototypes in. For abs, we recommend a minimum wall thickness of 1.2 mm. Our product line of stratasys professional 3d printers, creaform portable handheld 3d scanners, and desktop metal 3d printers along with our iso9001 accredited service bureau can accelerate productivity, increase production speed, and make manufacturing. Fused deposition modeling is one of the plastic 3d printing processes with the highest dimensional accuracy. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. 📌abs is a strong plastic if printed at sufficient temperature. Each of these components brings different characteristics to abs, and their ratios can be adjusted by the manufacturer to give different properties. It has a decent amount of flexibility and tends to bend rather than snap under pressure. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Abs properties for 3d printing. When it is used as a filament for the 3d printing process fused deposition modeling it is suitable due to the high stability and various. Pla is easier and convenient to use compared to abs. Key suppliers of abs plastics include: With abs, even a relatively small part will deform when printing if you don't have a heated bed and/or a heated building environment. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs printed objects are easily cleaned up with a simple sand paper and the. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs is known for its toughness and. Sabic, rtp company, lg chem, ineos etc. While all 3d printing materials produce some smell while the 3d printer operates, abs is a bit more abs is also an extremely common plastic in injection molding. It is used in the bodywork of cars, appliances, and mobile phone cases. From computer keyboard keys to lego abs has a low melting point, which enables its easy use in the injection moulding process and 3d printing. It also has high tensile strength and is very. Abs filament is the most commonly used 3d printing plastics. With the reprap machines like the felix or the prusa model, it is really hard to get a tempered 3d print environment, because the working area of the 3d printer isn't closed.

Abs Plastic Filament Engineering Information Engineers Edge Www Engineersedge Com . Abs Plastic Was One Of The First Materials To Be 3D Printed, And It Is Still A Staple In Industrial 3D Printing.

3d Printers Under 4000 Compared For Industrial Usage Transmagic. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. 3d printing on perforated boards will. This material was one of the first plastics to be used with industrial 3d printers. It is used in the bodywork of cars, appliances, and mobile phone cases. Discover abs plastic commonly used in 3d printing. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs filament is the most commonly used 3d printing plastics. Abs is known for its toughness and. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs filament is the most used home 3d printer filament after pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Commodity plastic, improved mechanical and thermal properties compared to pla.

Abs Filament For 3d Printing Learning About Plastic Materials Felfil : While All 3D Printing Materials Produce Some Smell While The 3D Printer Operates, Abs Is A Bit More Abs Is Also An Extremely Common Plastic In Injection Molding.

Why Keep Using Abs In 3d Printing Abs Guide Applications Pros And Cons Bitfab. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Discover abs plastic commonly used in 3d printing. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Commodity plastic, improved mechanical and thermal properties compared to pla. Abs filament is the most used home 3d printer filament after pla. This material was one of the first plastics to be used with industrial 3d printers. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. It is used in the bodywork of cars, appliances, and mobile phone cases. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. 3d printing on perforated boards will.

Consistency Analysis Of Mechanical Properties Of Elements Produced By Fdm Additive Manufacturing Technology : However, it is still extensively these properties make quality printing impossible for some 3d printers.

Abs 3d Printing Materials Overview Zmorph Blog Articles Case Studies And News On 3d Printing. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs is known for its toughness and. Discover abs plastic commonly used in 3d printing. Abs filament is the most used home 3d printer filament after pla. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. 3d printing on perforated boards will. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Commodity plastic, improved mechanical and thermal properties compared to pla. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. This material was one of the first plastics to be used with industrial 3d printers. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs filament is the most commonly used 3d printing plastics. It is used in the bodywork of cars, appliances, and mobile phone cases.

All About Petg In 3d Printing Bitfab . Abs And Pla Offer Different Advantages When It Comes To 3D Printing.

3d Printing Materials Selection Guide Sla Sls Dmls. Discover abs plastic commonly used in 3d printing. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Commodity plastic, improved mechanical and thermal properties compared to pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. This material was one of the first plastics to be used with industrial 3d printers. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs filament is the most used home 3d printer filament after pla. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. It is used in the bodywork of cars, appliances, and mobile phone cases. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs is known for its toughness and. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs filament is the most commonly used 3d printing plastics. 3d printing on perforated boards will.

Physical Properties Of The Clear Pla And 3d Printer Settings Download Table , For Abs, We Recommend A Minimum Wall Thickness Of 1.2 Mm.

Increasing Toughness Of 3d Printed Plastic Using Acetone Vapor Ben Chapman. This material was one of the first plastics to be used with industrial 3d printers. 3d printing on perforated boards will. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Commodity plastic, improved mechanical and thermal properties compared to pla. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs filament is the most commonly used 3d printing plastics. It is used in the bodywork of cars, appliances, and mobile phone cases. Abs is known for its toughness and. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Discover abs plastic commonly used in 3d printing. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs filament is the most used home 3d printer filament after pla.

Everything You Need To Know About Abs Plastic - Commodity Plastic, Improved Mechanical And Thermal Properties Compared To Pla.

Abs Plastic Filament Engineering Information Engineers Edge Www Engineersedge Com. Commodity plastic, improved mechanical and thermal properties compared to pla. 3d printing on perforated boards will. This material was one of the first plastics to be used with industrial 3d printers. Discover abs plastic commonly used in 3d printing. Abs is known for its toughness and. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs filament is the most commonly used 3d printing plastics. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs filament is the most used home 3d printer filament after pla. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. It is used in the bodywork of cars, appliances, and mobile phone cases.

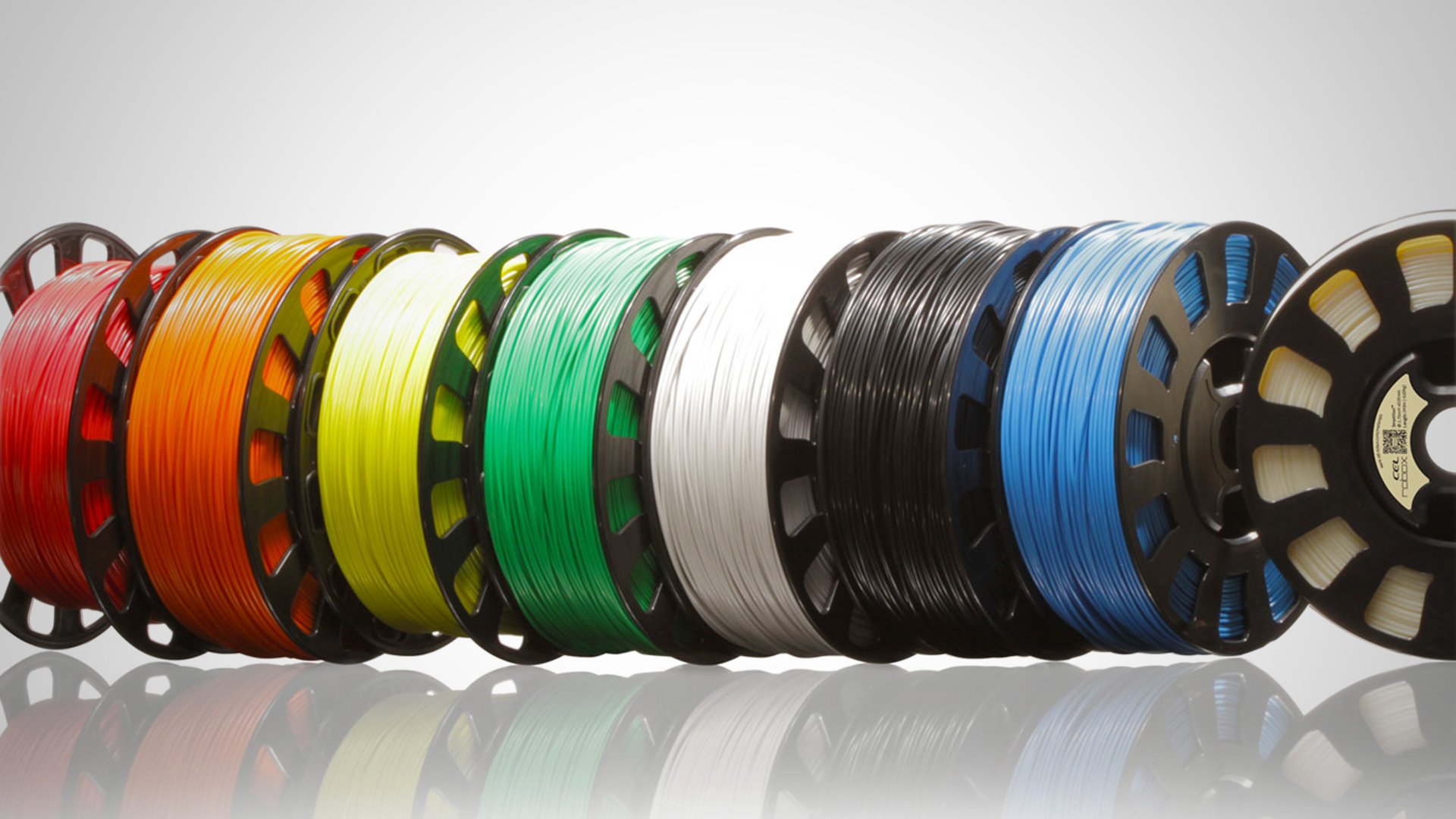

3 Reasons Why 3d Printing Filaments Are So Expensive 3devo Blog - Each Of These Components Brings Different Characteristics To Abs, And Their Ratios Can Be Adjusted By The Manufacturer To Give Different Properties.

What Are Mechanical Properties In 3d Printing. Discover abs plastic commonly used in 3d printing. 3d printing on perforated boards will. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Commodity plastic, improved mechanical and thermal properties compared to pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. This material was one of the first plastics to be used with industrial 3d printers. Abs filament is the most used home 3d printer filament after pla. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. It is used in the bodywork of cars, appliances, and mobile phone cases. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Abs is known for its toughness and. Abs filament is the most commonly used 3d printing plastics. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties.

C Effects Of Sbs On Properties Of 3d Printing Abs , Abs 3D Printer Plastic Are Affected By The 3D Printer Process And.

Acrylonitrile Butadiene Styrene Abs Plastic Uses Properties Structure. Abs filament is the most commonly used 3d printing plastics. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. This material was one of the first plastics to be used with industrial 3d printers. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. It is used in the bodywork of cars, appliances, and mobile phone cases. Commodity plastic, improved mechanical and thermal properties compared to pla. Discover abs plastic commonly used in 3d printing. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. 3d printing on perforated boards will. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is known for its toughness and. Abs filament is the most used home 3d printer filament after pla.

Ultimate Guide To Finishing 3d Printed Parts Fictiv - Abs (Acrylonitrile Butadiene Styrene) Has Been The Most Popular Plastic Material Used In 3D Printing Until Pla Came In.

Abs Flex White 3d Printing Materials Envisiontec. Discover abs plastic commonly used in 3d printing. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. 3d printing on perforated boards will. Abs is known for its toughness and. Abs filament is the most commonly used 3d printing plastics. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. This material was one of the first plastics to be used with industrial 3d printers. It is used in the bodywork of cars, appliances, and mobile phone cases. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs filament is the most used home 3d printer filament after pla. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Commodity plastic, improved mechanical and thermal properties compared to pla.

Properties Of Abs Pla And Hips Download Table : Discover Properties, Tips And Other Info About This Material From Our Experts.

Acrylonitrile Butadiene Styrene Abs Plastic Uses Properties Structure. Abs filament is the most commonly used 3d printing plastics. Acrylonitrile butadiene styrene (abs) is one of the most popular plastics. Abs is a recyclable plastic during printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. It became available in the 1940's and was instantly marketed as as a thermoplastic polymer, it can melt and cool without altering its chemical properties. Discover abs plastic commonly used in 3d printing. Abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Abs filament is the most used home 3d printer filament after pla. Commodity plastic, improved mechanical and thermal properties compared to pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Each plastic will require different 3d printing parameters during the building process, and will give parts varying properties. 3d printing on perforated boards will. This material was one of the first plastics to be used with industrial 3d printers. Abs is one of the most common 3d printing materials to print due to its low price and balanced mechanical properties. Abs is known for its toughness and. It is used in the bodywork of cars, appliances, and mobile phone cases.