3D Printing Abs Post Processing. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. It will also become unsustainable in large series production. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. This material was one of the first plastics to be used with industrial 3d printers. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. These materials are typically used for prints as well. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: It only takes a minute to sign up. Post processed fdm prints (from left to right): I'd like to smooth the outside of my pins with some type of post processing technique. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated.

3D Printing Abs Post Processing - Abs Requires Higher Temperature Of Melting.

3d Printing Post Processing Tricks Make Your Prints Shine. It will also become unsustainable in large series production. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. I'd like to smooth the outside of my pins with some type of post processing technique. These materials are typically used for prints as well. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. Post processed fdm prints (from left to right): One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. This material was one of the first plastics to be used with industrial 3d printers. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: It only takes a minute to sign up. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is.

It will also become unsustainable in large series production.

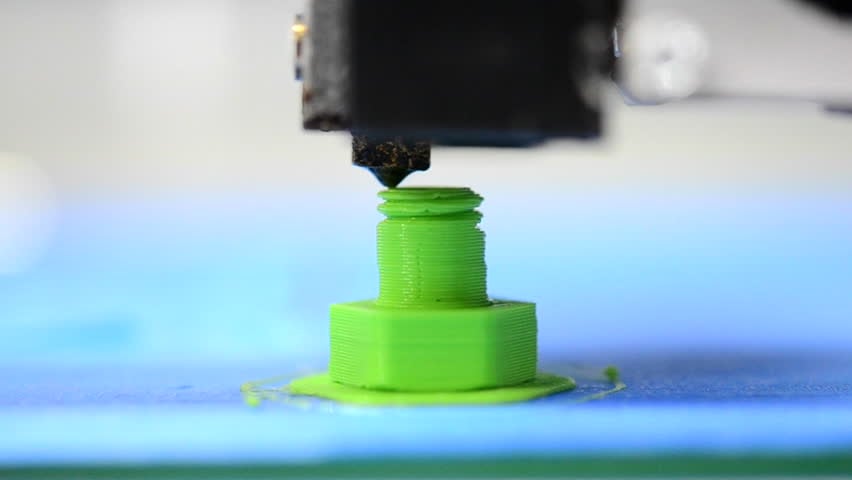

Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. The problem arises when printing large parts. I am having trouble printing abs with my heated bed not able to reach above 85c. Learn how to sand your 3d prints to create an amazing surface finish, or prepare them for painting or silicone molding. It's usually used whenever you need to 3d print some tough and durable models. Abs is considerably easy to sand. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Outside of 3d printing, abs is commonly used because of how useful its properties are. Slurry is prepared in the required. Abs requires higher temperature of melting. Fortunately, zmorph vx comes with magnetic covers and therefore 3d printing with abs is also possible. In fact, an array of consumer products are made of abs, from legos to. Allowing you to reduce your 3d printing cycle time and obtain the most realistic prototype for fit, form. This material was one of the first plastics to be used with industrial 3d printers. Why and how to process fdm and fff printed parts? Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: This higher glass transition temperature also makes sanding abs parts much easier because it does not soften and gum up sandpaper abs has a higher tolerance for heat compared to other plastics, making, 3d printed abs objects useful in environments where the parts encounter. Sometimes a 3d print serves as a blank. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Post processed fdm prints (from left to right): Since abs has a high shrinkage rate which causes warping, we will only print larger abs jobs with our abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. This is exactly where the post processing techniques come into play, converting your raw print into an extension of your imagination. Refine big prints with post processing. Abs requires a closed chamber for 3d printing. It will also become unsustainable in large series production. Hot abs filament gets through the nozzle of the 3d printer and cools down to 80 degrees celsius. Another method for joining abs parts is to use abs slurry. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Chemicals like acetone can be used to effectively smooth fdm parts made from pla or abs.

3d Printing Post Processing For Support Removal Surface Finishing . One Of The Easiest, And Most Effective, Ways To Smooth Your Abs Plastic Is With An Acetone Vapor.

Fdm 3d Printing Post Processing An Overview For Beginners All3dp. These materials are typically used for prints as well. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. It only takes a minute to sign up. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. It will also become unsustainable in large series production. I'd like to smooth the outside of my pins with some type of post processing technique. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. This material was one of the first plastics to be used with industrial 3d printers. Post processed fdm prints (from left to right): Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble:

Post Processing For Fdm Printed Parts 3d Hubs , These Materials Are Typically Used For Prints As Well.

Fdm 3d Printing Post Processing An Overview For Beginners All3dp. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. This material was one of the first plastics to be used with industrial 3d printers. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. It will also become unsustainable in large series production. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Post processed fdm prints (from left to right): It only takes a minute to sign up.

Postprocessing Of 3d Prints Step By Step Prusa Printers - It only takes a minute to sign up.

Abs Acetone Vapor Smoothing A Simple Guide All3dp. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. I'd like to smooth the outside of my pins with some type of post processing technique. It only takes a minute to sign up. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. This material was one of the first plastics to be used with industrial 3d printers. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. It will also become unsustainable in large series production. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. These materials are typically used for prints as well. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. Post processed fdm prints (from left to right):

How To Easily Cold Acetone Vapour Smooth Finish 3d Prints Step By S : In Terms Of Printing Supports, Abs Is Easily Printed With Hips, A Material That Has The Same Tray And Extrusion Temperatures.

How To Anneal Your 3d Prints For Strength. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: It only takes a minute to sign up. Post processed fdm prints (from left to right): One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. It will also become unsustainable in large series production. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. These materials are typically used for prints as well. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. This material was one of the first plastics to be used with industrial 3d printers. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. I'd like to smooth the outside of my pins with some type of post processing technique.

Post Processing In 3d Printing How Do Sls Sla And Fdm Compare Sinterit Manufacturer Of High Quality Desktop Sls 3d Printers , Take Ideas Beyond The Build Plate And Start Innovating Today!

Post Processing 3d Printed Parts Fdm Smoother Stronger. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. These materials are typically used for prints as well. Post processed fdm prints (from left to right): It will also become unsustainable in large series production. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. I'd like to smooth the outside of my pins with some type of post processing technique. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: It only takes a minute to sign up. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. This material was one of the first plastics to be used with industrial 3d printers. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties.

3d Printing Post Processing Techniques Makerbot , Chemicals Like Acetone Can Be Used To Effectively Smooth Fdm Parts Made From Pla Or Abs.

Post Processing Pla And Abs Prints Pinshape Blog. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. These materials are typically used for prints as well. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Post processed fdm prints (from left to right): Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. I'd like to smooth the outside of my pins with some type of post processing technique. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. It will also become unsustainable in large series production. It only takes a minute to sign up. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. This material was one of the first plastics to be used with industrial 3d printers. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize.

Ultimate Guide To Finishing 3d Printed Parts Fictiv : This Can Easily Be Done By Rubbing Acetone Onto Your Print Both Pla And Abs Are Safe For Kids If You Use A 3D Printer With A Closed Chamber Or Enclosure, But Without One, Pla Is Safer For Kids Than Abs.

Post Processing For Fdm Printed Parts 3d Hubs. It will also become unsustainable in large series production. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. I'd like to smooth the outside of my pins with some type of post processing technique. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Post processed fdm prints (from left to right): Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. It only takes a minute to sign up. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. This material was one of the first plastics to be used with industrial 3d printers. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. These materials are typically used for prints as well. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor.

3d Printing Polishing Machine For Pla Abs Model Post Processing 3d Printing Prints Post Processing - Learn How To Sand Your 3D Prints To Create An Amazing Surface Finish, Or Prepare Them For Painting Or Silicone Molding.

Abs Pla Or Copet What To Choose. This material was one of the first plastics to be used with industrial 3d printers. Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. I'd like to smooth the outside of my pins with some type of post processing technique. It will also become unsustainable in large series production. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. These materials are typically used for prints as well. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. It only takes a minute to sign up. Post processed fdm prints (from left to right): Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures.

Ultimate Guide To Finishing 3d Printed Parts Fictiv : Principles Outlined In 2010 For The Rapman Still Apply To Printers Sold In 2017.

7 Steps To Shiny Porcelain Finish On 3d Printed Abs Parts With Acetone. It will also become unsustainable in large series production. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. It only takes a minute to sign up. I'd like to smooth the outside of my pins with some type of post processing technique. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. These materials are typically used for prints as well. Post processed fdm prints (from left to right): Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: This material was one of the first plastics to be used with industrial 3d printers.

Abs Vs Petg Which Is Best For 3d Printing 3dsourced - Abs Is A Low Cost Material, Good For Printing Tough And Durable Parts That Withstand High Temperatures.

3d Print Post Processing Solutions To Buy A 3d Printer. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Cold welding, gap filling, unprocessed, sanded, polished, painted and epoxy coated. Ideally i'd like to keep the pins as close to dimensionally accurate as possible, but i realize. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. These materials are typically used for prints as well. It only takes a minute to sign up. I'd like to smooth the outside of my pins with some type of post processing technique. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Dissolvable support structures are easier to remove, but require a dual extruder printer insoluble: It will also become unsustainable in large series production. Post processed fdm prints (from left to right): Insoluble materials are the normal printing materials like pla, abs, nylon, or pc. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. This material was one of the first plastics to be used with industrial 3d printers.