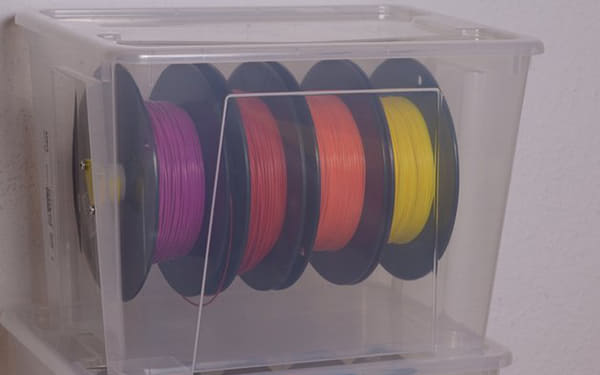

3D Printing Abs Properties. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is known for its toughness and. Improve your print quality with advice from our experts. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. These properties make quality printing impossible for some 3d printers. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Commodity plastic, improved mechanical and thermal properties compared to pla. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures.

3D Printing Abs Properties : Senb Besides, Printing Platform Temperature And Textile Properties Influence The Tensile And Deformation Properties Of The 3D Printed Pla On Pet Textile.

Choose Titanx To Get High Performance Functional Parts Titanx Is An Industrial Grade Fff Fdm Optimized Abs Based Engineering Filament It Is The Evolution Of. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. These properties make quality printing impossible for some 3d printers. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. Improve your print quality with advice from our experts. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Abs is known for its toughness and. Commodity plastic, improved mechanical and thermal properties compared to pla.

Known for its great mechanical properties, ability to withstand high temperatures, and low cost, abs filament is a favorite among makers and prototypers who want.

Therefore, 3d printing prototypes in abs gives designers a good idea of how an. A printer with a heated print bed is also usually needed as abs will stick to a hot print bed. The problem arises when printing large parts. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Pla, abs, and nylon are three of the most popular 3d printing materials. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Pla vs abs 3d printing: Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. There are many types of filament available with different properties, requiring different temperatures to print. Pro series abs 3d printing filament properties: However, the most popular plastics there are times when the answer to this comparison pla vs abs plastic depends on the object that you will be 3d printing. (2017) experimental characterization of the mechanical properties of 3d printed abs and polycarbonate parts. Acrylonitrile butadiene styrene (abs) is a commonly used thermoplastic as it is lightweight and can both be injection molded and extruded. Abs does expand and warp. Abs is known for its toughness and. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. 2 physical properties of printing materials. Pla and abs do not share. Digital image correlation 3d printing additive manufacturing mechanical properties of materials rapid prototyping anisotropy abs polycarbonate. Since abs has a high shrinkage rate which causes warping, we will only print larger abs jobs with. Abs filament is a stiff but brittle 3d printing material. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Printing materials (filament) can be characterized in various ways. Download cura abs profile & 3d printing material settings today! Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. 3d printing filament is the thermoplastic feedstock for fused deposition modeling 3d printers. Commodity plastic, improved mechanical and thermal properties compared to pla. Thinking about 3d printing with abs filament?

Abs 3d Printing Blog , The Horizontally Printed Model Clearly Shows The Staircase Effect Of The Printing Process.

Top 5 Things To Know About 3d Printing Abs Parts. Abs is known for its toughness and. Improve your print quality with advice from our experts. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Commodity plastic, improved mechanical and thermal properties compared to pla. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. These properties make quality printing impossible for some 3d printers. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature.

3d Printing In Abs Fdm 3d Print Service Beamler : There Are Many Types Of Filament Available With Different Properties, Requiring Different Temperatures To Print.

Top 5 Things To Know About 3d Printing Abs Parts. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Improve your print quality with advice from our experts. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Commodity plastic, improved mechanical and thermal properties compared to pla. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties.

Abs Plastic Material For 3d Printing Fdm Thermoplastic Material : Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile.

Material Properties Of Pla And Abs 22 23 Download Table. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Abs is known for its toughness and. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Commodity plastic, improved mechanical and thermal properties compared to pla. Improve your print quality with advice from our experts. These properties make quality printing impossible for some 3d printers. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding.

Fdm 3d Printing Materials Compared 3d Hubs - Best Used For Interlocking Parts Like Gears, Parts Exposed To Uv And Heat Like A Car Cup Holder, Or Prototyping.

25 Best Types Of 3d Printer Filament Comparison Charts Athorbot. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Commodity plastic, improved mechanical and thermal properties compared to pla. These properties make quality printing impossible for some 3d printers. Improve your print quality with advice from our experts. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is known for its toughness and. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature.

What Material Should I Use For 3d Printing 3d Printing For Beginners : Pla Vs Abs 3D Printing:

Polymers Free Full Text Fdm 3d Printing Of Polymers Containing Natural Fillers A Review Of Their Mechanical Properties Html. Commodity plastic, improved mechanical and thermal properties compared to pla. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. These properties make quality printing impossible for some 3d printers. Improve your print quality with advice from our experts. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs is known for its toughness and. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties.

3d Printing Technology Objet Polyjet 3d Printing Verowhiteplus : A Printer With A Heated Print Bed Is Also Usually Needed As Abs Will Stick To A Hot Print Bed.

Functional 3d Printed Prototype 3d Printed Fdm Abs Jigs Fixtures Mold Design 3dpritning Rapidprototyping Vexmatech Abs Material What Is Abs Prints. Commodity plastic, improved mechanical and thermal properties compared to pla. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Improve your print quality with advice from our experts. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. These properties make quality printing impossible for some 3d printers. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is known for its toughness and. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile.

Ultimate 3d Printing Material Properties Table , Therefore, 3D Printing Prototypes In Abs Gives Designers A Good Idea Of How An.

Abs Filament The Complete Guide Best Abs 3d Printers 3dsourced. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. These properties make quality printing impossible for some 3d printers. Commodity plastic, improved mechanical and thermal properties compared to pla. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Improve your print quality with advice from our experts. Abs is known for its toughness and. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional.

Consistency Analysis Of Mechanical Properties Of Elements Produced By Fdm Additive Manufacturing Technology . Even Outside Of The 3D.

C Effects Of Sbs On Properties Of 3d Printing Abs. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Abs is known for its toughness and. Commodity plastic, improved mechanical and thermal properties compared to pla. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. These properties make quality printing impossible for some 3d printers. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. Improve your print quality with advice from our experts. As a thermoplastic polymer, it can melt and cool without altering its chemical properties.

What Are Mechanical Properties In 3d Printing , 2 Physical Properties Of Printing Materials.

Polymers Free Full Text Fdm 3d Printing Of Polymers Containing Natural Fillers A Review Of Their Mechanical Properties Html. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Improve your print quality with advice from our experts. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile. Abs is known for its toughness and. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). As a thermoplastic polymer, it can melt and cool without altering its chemical properties. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. These properties make quality printing impossible for some 3d printers. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Commodity plastic, improved mechanical and thermal properties compared to pla.

3d Printer Filament Comparison Matterhackers - As A Thermoplastic Polymer, It Can Melt And Cool Without Altering Its Chemical Properties.

Consistency Analysis Of Mechanical Properties Of Elements Produced By Fdm Additive Manufacturing Technology. Abs is a common thermoplastic with good mechanical properties and excellent impact strength, superior to pla but with less defined details. These properties make quality printing impossible for some 3d printers. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs printed objects are easily cleaned up with a simple sand paper and the object this being said, pla is the perfect 3d printing material for hobbyists and home 3d printer enthusiasts, while abs, due to its properties, is. As a thermoplastic polymer, it can melt and cool without altering its chemical properties. When printing abs on these printers, we recommend closing the lid to maintain a higher internal temperature. Improve your print quality with advice from our experts. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Though not quite as durable as nylon, parts printed from abs is also an extremely common plastic in injection molding. Abs is known for its toughness and. When printing, you will smell foul odors („there's nothing like the stench of abs filament in the morning, as our maker friends say). Commodity plastic, improved mechanical and thermal properties compared to pla. Available in the form of filaments with a diameter of 1.75 mm or 2.85 mm and in several colours, abs has interesting properties for many industries that want to 3d print functional. Many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Senb besides, printing platform temperature and textile properties influence the tensile and deformation properties of the 3d printed pla on pet textile.