3D Printing Carbon Fiber Temperature. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Let's find out how it performs! Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Carbon fiber 3d printing pros and cons. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. The carbon material explained for 3d printing. Carbon itself is the building block of life. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Starter temperatures & printing guide. I've finally tested the 20% carbon fiber filled filament from colorfabb. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts.

3D Printing Carbon Fiber Temperature . The Carbon Material Explained For 3D Printing.

3dtalk China Cheap Nylon Combo Carbon Fiber 3d Printing High Temperature Resistance China Fdm Consumabale Materials For 3d Printer Pla Material. Carbon itself is the building block of life. The carbon material explained for 3d printing. Starter temperatures & printing guide. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. Let's find out how it performs! Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Carbon fiber 3d printing pros and cons. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. I've finally tested the 20% carbon fiber filled filament from colorfabb.

Whether they use chopped carbon fiber, carbon nanotubes or continuous carbon fiber, the majority of 3d printing technologies still suffer from a while markforged machines are desktop printers, emerging carbon fiber 3d printing technologies may require a dedicated production facility or.

What is carbon fiber filament? The high amount of carbon fibers makes this material extremely abrasive, so i obtained a hardened steel nozzle for my e3dv6 hotend to print it without yet, petg filaments are fairly undemanding to the printer hardware: And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. What is carbon fiber filament? How are carbon fibers used in 3d printing? I've finally tested the 20% carbon fiber filled filament from colorfabb. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Carbon fiber printing is nothing new. In fact, continuous carbon fiber 3d printing is. The carbon material explained for 3d printing. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. The dual matrix system is compatible with thermoplastic processing temperatures up to 270˚c. Carbon fiber 3d printing pros and cons. Let's find out how it performs! I've always loved aviation and flying machines, so when small rc helicopters and multicopters became affordable, i knew that i had to buy one. Requires high temperatures for printing. Carbon fiber filaments — like this one from matterhackers that uses nylon. Carbon fiber filament uses short carbon fibers, consisting of segments of less than one millimeter in length, which are mixed with a thermoplastic known as since the carbon fiber is not chopped up into smaller pieces, it retains much more of its strength. This will also aid in reducing the chances of clogging. Lightweight prints, supports for abs prints. No high nozzle or bed temperatures, no heated build chambers and also no. Carbon itself is the building block of life. Whether they use chopped carbon fiber, carbon nanotubes or continuous carbon fiber, the majority of 3d printing technologies still suffer from a while markforged machines are desktop printers, emerging carbon fiber 3d printing technologies may require a dedicated production facility or. The prints produced using this material are also it may be necessary to set the temperature for the extruder at 40°c higher than the usual setting. Which 3d printing material should you choose? Nylon carbon fiber is a reinforced nylon material with added micro carbon fibers, nylon carbon fiber is an engineering grade filament, designed for desktop 3d printing. Starter temperatures & printing guide. If you don't have access to a 3d printer, you could commission someone from 3d hubs to do the printing for you. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. Afterwards, carbon fiber strings pass through a surface treatment bath to etch the surface of the carbon.

China Carbon Fiber Reinforced High Temperature 3d Printer Pla Filament Photos Pictures Made In China Com , I'vE Finally Tested The 20% Carbon Fiber Filled Filament From Colorfabb.

Amazon Com Bczamd 3d Printer Hardened Steel V6 Nozzles 0 4mm For High Temperature 3d Printing Pei Peek Carbon Fiber Pla Filament 1 75mm For 3d Tit Aero Lit6 Hotend Prusa I3 Mk2 2pcs Industrial. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Carbon fiber 3d printing pros and cons. The carbon material explained for 3d printing. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Starter temperatures & printing guide. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Let's find out how it performs! I've finally tested the 20% carbon fiber filled filament from colorfabb. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Carbon itself is the building block of life.

Yg08n3iku Bumm - Its Abundance (As The Fourth Most Common Element In The Universe) And Its Unique Ability To Form Polymers At Common Earth Temperatures Makes It Super Versatile.

Printing With 3dxtech Carbon Fiber Petg Solved Paynter S Palace. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. I've finally tested the 20% carbon fiber filled filament from colorfabb. The carbon material explained for 3d printing. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. Carbon itself is the building block of life. Starter temperatures & printing guide. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon fiber 3d printing pros and cons. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results.

Mk8 Nozzle High Temperature Hardened Steel Mk8 Nozzles For 3d Printer Pei Peek Carbon Fiber Filament For E3d Hotend Extruder Aliexpress , And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer.

3d Print Strong Parts With Carbon Fiber Advanced Materials Stratasys. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. Carbon fiber 3d printing pros and cons. The carbon material explained for 3d printing. I've finally tested the 20% carbon fiber filled filament from colorfabb. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Let's find out how it performs! Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. Starter temperatures & printing guide. Carbon itself is the building block of life. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials.

The First High Temperature Continuous Carbon Fiber 3d Printer Is Coming Fabbaloo . Let's Find Out How It Performs!

Suntop Pla Filament 3d Printer Filament Carbon Fiber Filament 1 75mm 20 Carbon Ebay. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Let's find out how it performs! Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. The carbon material explained for 3d printing. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Starter temperatures & printing guide. I've finally tested the 20% carbon fiber filled filament from colorfabb. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Carbon fiber 3d printing pros and cons. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. Carbon itself is the building block of life. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints.

3d Print Strong Parts With Carbon Fiber Advanced Materials Stratasys - Carbon Fiber Filaments Use Tiny Fibers That Are Infused Into A Base Material To Improve The Properties Of That Material.

Everything You Need To Know About Carbon Fiber 3d Printing Makerbot. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. The carbon material explained for 3d printing. Let's find out how it performs! I've finally tested the 20% carbon fiber filled filament from colorfabb. Carbon fiber 3d printing pros and cons. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Carbon itself is the building block of life. Starter temperatures & printing guide. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile.

Tailoring Strength And Modulus By 3d Printing Different Continuous Fibers And Filled Structures Into Composites Springerlink : Carbon Fiber Filament Uses Short Carbon Fibers, Consisting Of Segments Of Less Than One Millimeter In Length, Which Are Mixed With A Thermoplastic Known As Since The Carbon Fiber Is Not Chopped Up Into Smaller Pieces, It Retains Much More Of Its Strength.

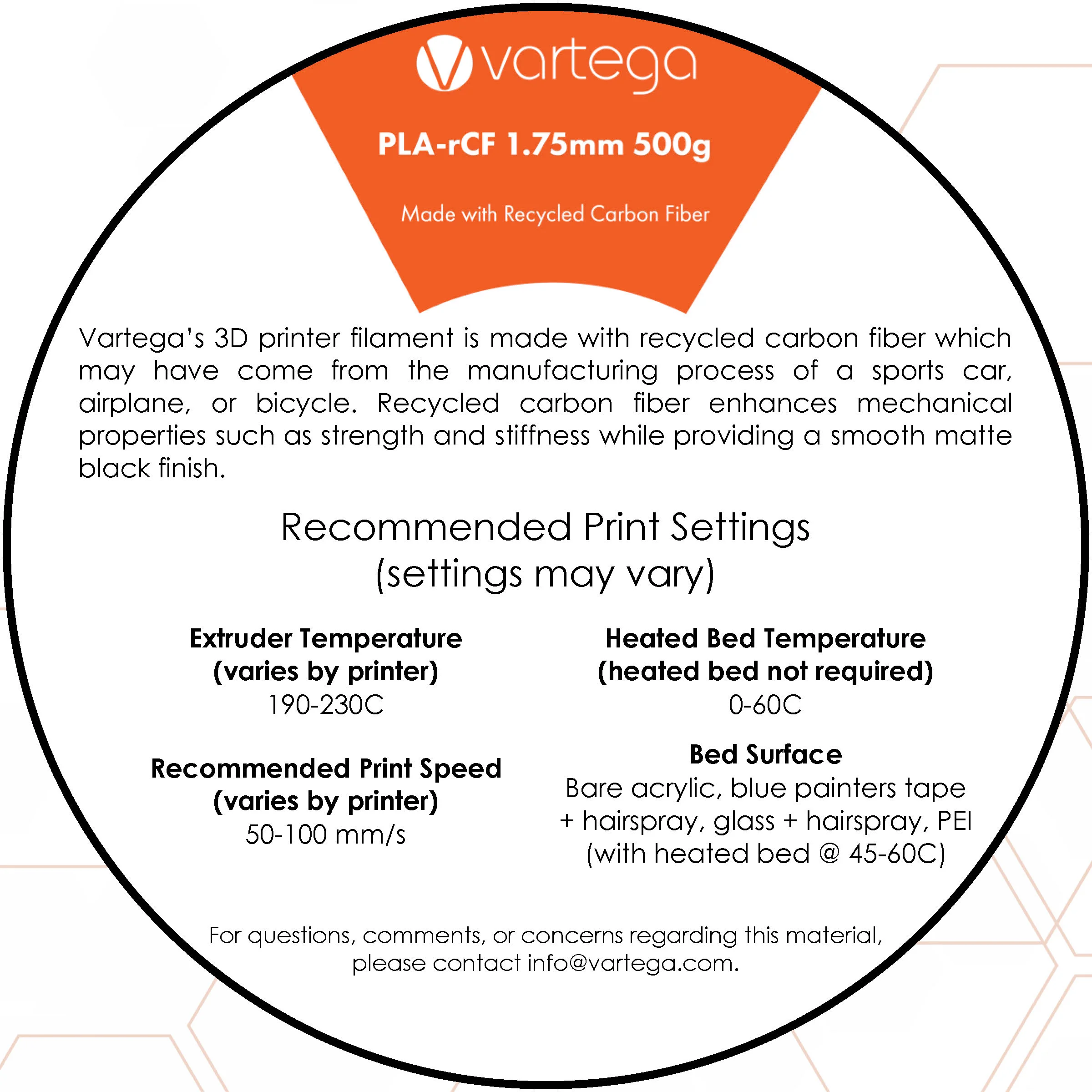

Vartega Vartegafil Recycled Carbon Fiber 3d Printer Filament Vartega. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Let's find out how it performs! Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. I've finally tested the 20% carbon fiber filled filament from colorfabb. Carbon fiber 3d printing pros and cons. The carbon material explained for 3d printing. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Carbon itself is the building block of life. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. Starter temperatures & printing guide.

High Temperature Carbon Fiber 3d Printer 160 160 200 Mm Build Volume For Sale Carbon Fiber 3d Printer Manufacturer From China 109051590 . Carbon Fiber 3D Printing Pros And Cons.

Thermal Properties Of Our Filaments 3dxtech. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Starter temperatures & printing guide. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. I've finally tested the 20% carbon fiber filled filament from colorfabb. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. The carbon material explained for 3d printing. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Let's find out how it performs! As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Carbon itself is the building block of life. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. Carbon fiber 3d printing pros and cons.

Interface And Performance Of 3d Printed Continuous Carbon Fiber Reinforced Pla Composites Sciencedirect - In Fact, We'vE Already Seen A Company Called Markforged Debut A Printer That Can Print Objects With Carbon Fiber While This Article Focused Mainly On The Ability To 3D Print Super Strong Objects By Embedding Carbon Fibers And Other Materials Into Them, That Is Just A.

Desktop Metal Introduces Carbon Fiber 3d Printer Engineering Com. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon itself is the building block of life. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. The carbon material explained for 3d printing. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Starter temperatures & printing guide. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. Carbon fiber 3d printing pros and cons. I've finally tested the 20% carbon fiber filled filament from colorfabb. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Let's find out how it performs! This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts.

1pc Hardened Steel Volcano Nozzles For High Temperature 3d Printing Pei Peek Carbon Fiber Filament For E3d Volcano Hotend 3d Printer Parts Accessories Aliexpress . Whether They Use Chopped Carbon Fiber, Carbon Nanotubes Or Continuous Carbon Fiber, The Majority Of 3D Printing Technologies Still Suffer From A While Markforged Machines Are Desktop Printers, Emerging Carbon Fiber 3D Printing Technologies May Require A Dedicated Production Facility Or.

All You Need To Know About Carbon Fiber For 3d Printing 3dnatives. The carbon material explained for 3d printing. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Carbon itself is the building block of life. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. I've finally tested the 20% carbon fiber filled filament from colorfabb. Let's find out how it performs! Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Carbon fiber 3d printing pros and cons. Starter temperatures & printing guide.

Amazon Com Qdtd Pc Carbon Fiber Filament 1 75mm 3d Printing Filament 1kg For 3d Printer Black Home Kitchen - The Carbon Material Explained For 3D Printing.

An Investigation Into 3d Printing Of Fibre Reinforced Thermoplastic Composites Sciencedirect. Carbon fiber filaments use tiny fibers that are infused into a base material to improve the properties of that material. I've finally tested the 20% carbon fiber filled filament from colorfabb. Carbon fiber filaments offer incredible mechanical properties, but be prepared to do some tinkering on your own in order to maximize the quality of your prints. Let's find out how it performs! Carbon itself is the building block of life. This machine can reach nozzle temperatures of up to 500°c, allowing you to print with carbon peek, carbon pa, ultem, peek, glass pa, and a variety of other technical materials. Carbon fiber 3d printing pros and cons. Its abundance (as the fourth most common element in the universe) and its unique ability to form polymers at common earth temperatures makes it super versatile. The carbon material explained for 3d printing. Several popular filaments can be print settings, such as printing temperature, speed, bed adhesion, and extrusion rates will be very similar to the normal settings used for the base material. And so, the first thing on your carbon fiber 3d printing checklist should be to check the maximum extruder temperature of your 3d printer. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. As each desktop 3d printer has its own unique characteristics, you might need to tweak around with your temperature settings a bit to get the best results. Chopped carbon fiber 3d printing materials can be used like normal 3d printing plastics, boosting some material properties. Starter temperatures & printing guide.