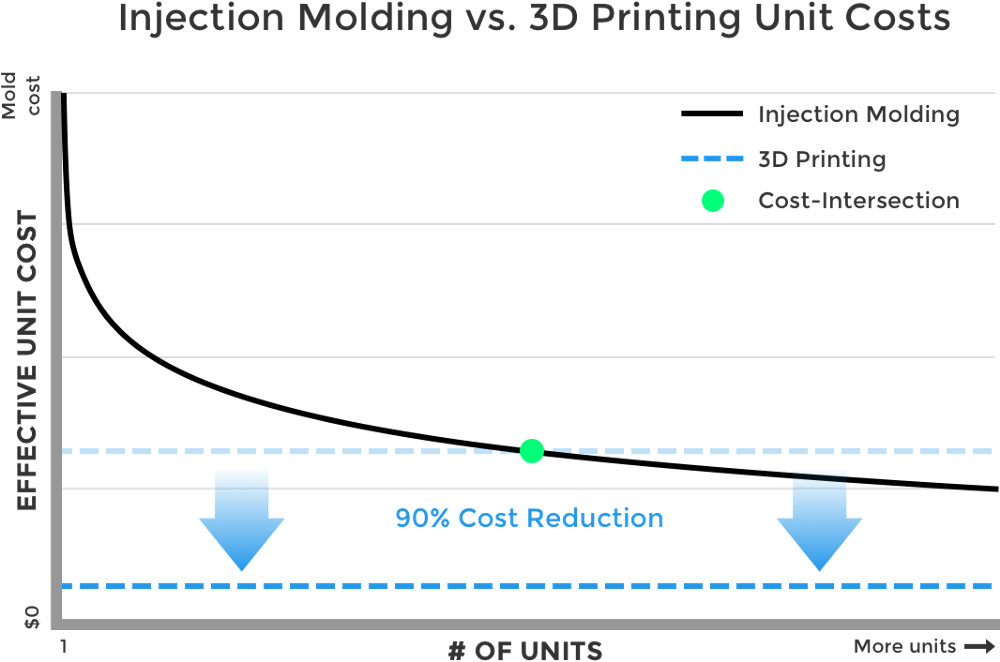

3D Printing Cost Vs Injection Molding. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. The main differences between 3d printing vs injection molding are: Learn more in this handy guide! Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. All3dp is an editorially independent publication. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. In injection molding you are. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions The two processes are entirely different. Editorial content, on principle, can not be bought or influenced.

3D Printing Cost Vs Injection Molding , Some Might Wonder Why We Can't Just 3D Print A Bunch Of Plastic Parts For A Client Instead Of Investing In An Injection Mold.

Is 3d Printing Replacing Conventional Manufacturing Vendop. Learn more in this handy guide! Editorial content, on principle, can not be bought or influenced. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: All3dp is an editorially independent publication. In injection molding you are. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. The main differences between 3d printing vs injection molding are: Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. The two processes are entirely different. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce.

Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true.

Manufacturing cost was dramatically reduced because there was no assembly and none of the tooling that would. Editorial content, on principle, can not be bought or influenced. The material must have both high stiffness and must be able to operate at elevated temperatures. When you injection mold there is a fixed tooling cost. For this specific job, the. Each one of these technologies has its own injection moulding vs. After that, the cost per unit is lower than 3d printing and the i am printing a part now for a medical device i am designing. This is also why we use five. What are your thoughts on the two processes? Learn more in this handy guide! Injection molding is a very demanding tooling application: This is because 3d printing becomes exponentially more expensive as volume increases. Production injection molds are built to withstand higher volumes of plastic injection molding cycles. 3d printing vs injection molding. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. Would you prefer plastic injection molding or 3d printing? Let's take a look at pros and cons. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: Revised cost model considerations for injection molding versus conventional cost model. What are the advantages in terms of cost and flexibility? In injection molding you are. However, the true costs associated with producing a part using injection molding are not as. An injection molding machine could make it in about 15. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an injection mold. In this case, what is 3d printing reduced four parts to two. All3dp is an editorially independent publication. The main differences between 3d printing vs injection molding are: To retain their accuracy over multiple runs, 3d printing materials for manufacturing injection molds must have a high stiffness. On the contrary, plastic injection molding processes required higher initial cost because of the high cost of manufacturing the necessary special molds. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing.

Pricing For 3d Printing Vs Injection Molding Sd3d Printing : In Injection Molding You Are.

3d Printing Or Injection Molding Guide To Cost Efficiency. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. All3dp is an editorially independent publication. Learn more in this handy guide! Editorial content, on principle, can not be bought or influenced. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. The two processes are entirely different. The main differences between 3d printing vs injection molding are: In injection molding you are.

3d Printing Vs Cnc Machining 3d Hubs - Injection Molding Requires Expensive Mold Tools With High Cost Internal Cavity Designs That Don't Make Sense Unless You Need To Do Consumer Research Or So What's The Difference Between Injection Molding And 3D Printing?

3d Printing Or Injection Molding Guide To Cost Efficiency. Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. The two processes are entirely different. All3dp is an editorially independent publication. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: In injection molding you are. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing.

Blow Molding Vs Injection Molding What S The Difference The Rodon Group . 3d printing and injection molding are not competing, but rather complementary ways of manufacturing.

Oecd Ilibrary Home. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. The main differences between 3d printing vs injection molding are: Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. In injection molding you are. Editorial content, on principle, can not be bought or influenced. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: All3dp is an editorially independent publication. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. The two processes are entirely different. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce.

Making Injection Molding Cost Effective How Many Units Do You Need To Order 3dprint Com The Voice Of 3d Printing Additive Manufacturing : On The Contrary, Plastic Injection Molding Processes Required Higher Initial Cost Because Of The High Cost Of Manufacturing The Necessary Special Molds.

How To Do Your Own Desktop Injection Molding From 3d Printed Molds Core77. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. In injection molding you are. The two processes are entirely different. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Editorial content, on principle, can not be bought or influenced. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. All3dp is an editorially independent publication. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. The main differences between 3d printing vs injection molding are: Learn more in this handy guide! Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost:

Choosing Between 3d Printing Amp Cnc Machining Core77 : See Injection Molding With A Hot Glue Gun, And With Real Machines.

3d Printing Vs Injection Molding Cost And Quality Analysis Online 3d Printing Service Fast Affordable Fdm Mjf Sls. Editorial content, on principle, can not be bought or influenced. In injection molding you are. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. The two processes are entirely different. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Learn more in this handy guide! Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions The main differences between 3d printing vs injection molding are: A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. All3dp is an editorially independent publication.

Injection Molding Vs 3d Printing Hydra Research : This Is Because 3D Printing Becomes Exponentially More Expensive As Volume Increases.

Professional 3d Printer For Industry 3d Center. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. In injection molding you are. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions All3dp is an editorially independent publication. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. Editorial content, on principle, can not be bought or influenced. The two processes are entirely different. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. The main differences between 3d printing vs injection molding are: Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing.

Choosing Between 3d Printing Amp Cnc Machining Core77 : When You Injection Mold There Is A Fixed Tooling Cost.

Cutting Time And Costs Of Moulds With 3d Printing Plastix World. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. The main differences between 3d printing vs injection molding are: Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? The two processes are entirely different. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. In injection molding you are. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions All3dp is an editorially independent publication. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. Learn more in this handy guide! 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Editorial content, on principle, can not be bought or influenced.

Cost To Manufacture With Injection Molding Carbon3d , Is 3D Metal Printing (Binder Jetting) Better Than Mim?

3ders Org Is 3d Printing A Viable And Affordable Alternative To Injection Molding Production 3d Printer News 3d Printing News. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? In injection molding you are. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. The two processes are entirely different. The main differences between 3d printing vs injection molding are: Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. All3dp is an editorially independent publication. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. Editorial content, on principle, can not be bought or influenced. Learn more in this handy guide! 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost:

3d Printed Injection Mold All You Need To Know All3dp : When You Injection Mold There Is A Fixed Tooling Cost.

Injection Molding Vs 3d Printing Hydra Research. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions The main differences between 3d printing vs injection molding are: Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. The two processes are entirely different. In injection molding you are. All3dp is an editorially independent publication. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Editorial content, on principle, can not be bought or influenced. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency.

Will 3d Printing Upset The Injection Molding Industry : Although Cost Per Unit Is An Important Figure, There Are Several Hidden Costs That Managers Should Also Take Into Consideration When Making Manufacturing Decisions

3d Printing Vs Injection Molding Know The Difference Total 3d Printing. The main differences between 3d printing vs injection molding are: In injection molding you are. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold that cost: 3d printing is more expensive, whereas injection molding is a cheaper variant for bigger produce. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what they should be used for. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding machines are typically found in dedicated shops that specialize or offer that capability to a number of customers. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Editorial content, on principle, can not be bought or influenced. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Learn more in this handy guide! The two processes are entirely different. All3dp is an editorially independent publication. A comparison of 3d printing and injection molding for short series production to optimize cost efficiency. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions