3D Printing Extrusion Issues. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. This is very important when 3d. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. It is easy to upgrade and there is a large community surrounding its use. The printer failed to provide the amount of plastic required for printing the skipped layers. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways:

3D Printing Extrusion Issues - It Is Easy To Upgrade And There Is A Large Community Surrounding Its Use.

Troubleshooting Extrusion Problems In 3d Printers Zortrax Support Center. It is easy to upgrade and there is a large community surrounding its use. The printer failed to provide the amount of plastic required for printing the skipped layers. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. This is very important when 3d. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament.

When the line width is adjusted to 0.35mm, we can see that the printing effect is basically great, but when the thickness is 2mm and 2.25mm, the fineness of printing is not as good as the line width of.

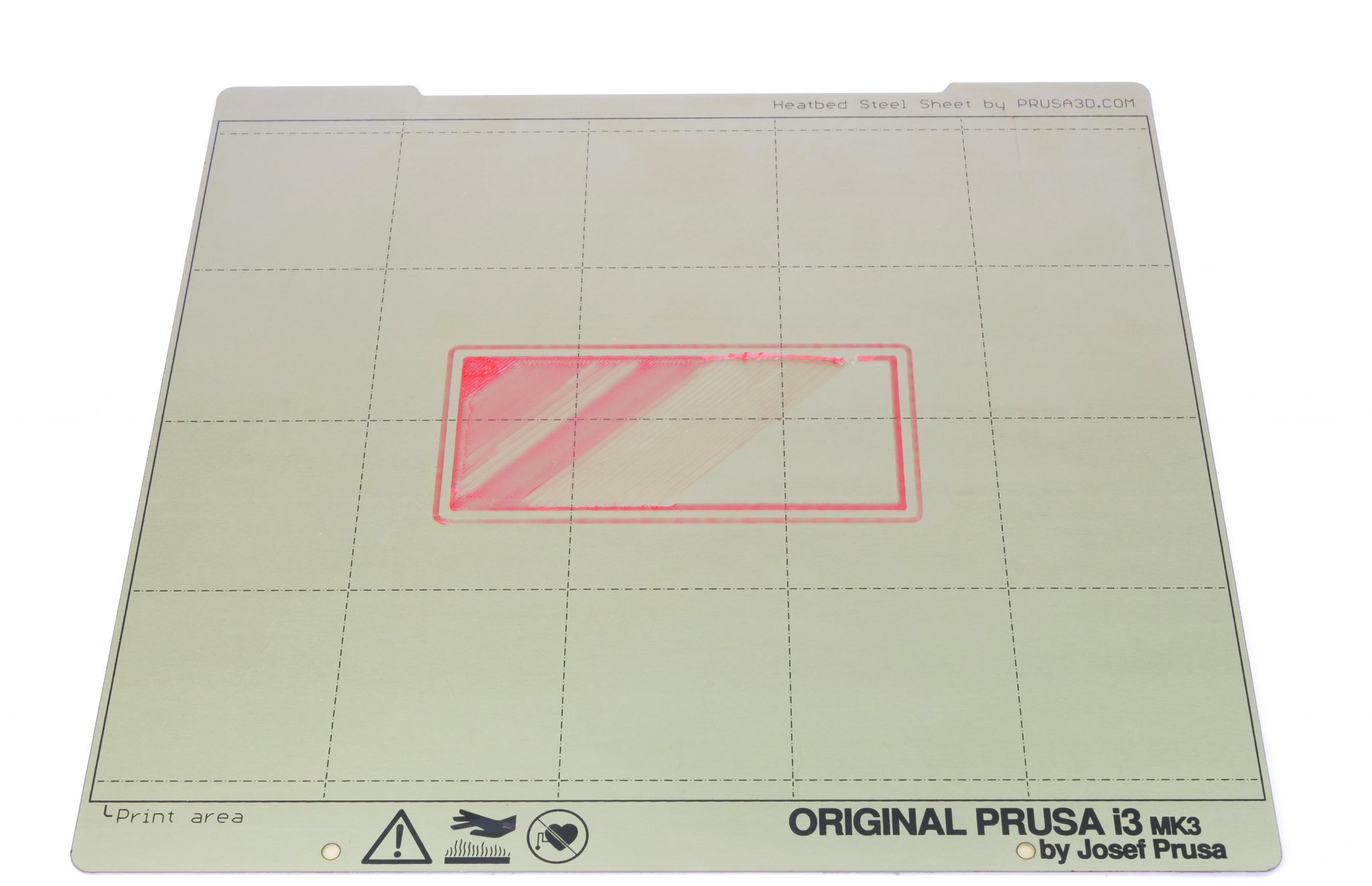

When printing both the supports and model in printing with the correct nozzle temperature will solve this issue. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. I mean in normal conditions we thanks for contributing an answer to 3d printing stack exchange! This is very important when 3d. Extrusion temperature is too low, the wire dries too fast or shrinks and therefore does not stick to the adjacent wire. Assembly manuals, print quality troubleshooting, calibration, prusaslicer and much. According to studies at the wake forest university, scientists will be able to do this by incorporating cells in 3d printing. Journal of manufacturing processes, vol. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. Creating extrusions with holes using connect. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. For aftersale issues, just submit a ticket. Please be sure to answer the question. Let's talk about how to avoid it. Too much friction on the filament feeding path can result in under extrusion. We will reply within 24 hours. When the line width is adjusted to 0.35mm, we can see that the printing effect is basically great, but when the thickness is 2mm and 2.25mm, the fineness of printing is not as good as the line width of. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I try to print a dual extrusion object and having issues with the outer contour of the object. By carefully observing the printing process, you can identify problems with extrusion instability. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: Next, let's analyze the contents of the form. Process study and material characterization. Avoid slowing down too much in this area, even if the printing time of the layer is low. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). Another issue is that people will draw their…splines in something other than the xy view.…a simple correction is to just take your spline and 9. The proposed extrusion model enables printing with. Your printer works and can print with satisfactory results. I noticed that there are a lot of people who experience z banding, inconsistent extrusion or other issues in their prints. All information you need to know about original prusa 3d printers. Consumption, color and material limitations for fine and.

Most Common 3d Printing Problems With Solutions Technology Outlet : I Noticed That There Are A Lot Of People Who Experience Z Banding, Inconsistent Extrusion Or Other Issues In Their Prints.

Ultimate 3d Print Quality Troubleshooting Guide 2018 All 44 Problems. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. The printer failed to provide the amount of plastic required for printing the skipped layers. This is very important when 3d. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. It is easy to upgrade and there is a large community surrounding its use.

Important Things To Know About Dual Extrusion In 3d Printers , Creating Extrusions With Holes Using Connect.

How To Fix The Most Common 3d Printing Errors Prusa Printers. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: The printer failed to provide the amount of plastic required for printing the skipped layers. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them.

Is Your 3d Print Failing We Found A Troubleshooting Guide For You Fabbaloo , Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts.

3d Printer Tool Set Your Extruder Steps With Ease Hackaday. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. The printer failed to provide the amount of plastic required for printing the skipped layers. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. It is easy to upgrade and there is a large community surrounding its use. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament.

Under Extrusion Towards The End Of The Print 3d Printing Stack Exchange . There Are Several Things You Should Know To Avoid Getting Clogs And Extrusion Problems.

Another Issue Batches Of Over Extrusion On The Corners Or Retraction Issue 3dprinting. It is easy to upgrade and there is a large community surrounding its use. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. This is very important when 3d. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. The printer failed to provide the amount of plastic required for printing the skipped layers. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament.

Underextruding After Retraction Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts . For Aftersale Issues, Just Submit A Ticket.

Six Good 3d Printing Troubleshooting Guides Fabbaloo. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. It is easy to upgrade and there is a large community surrounding its use. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. The printer failed to provide the amount of plastic required for printing the skipped layers. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled.

Print Quality Guide - It Is Easy To Upgrade And There Is A Large Community Surrounding Its Use.

Issues With Under Extrusion On One Side Of Print 3d Printing 3d Printers Talk Manufacturing 3d Hubs. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. The printer failed to provide the amount of plastic required for printing the skipped layers. It is easy to upgrade and there is a large community surrounding its use. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. This is very important when 3d. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them.

Inconsistent Extrusion , I Noticed That There Are A Lot Of People Who Experience Z Banding, Inconsistent Extrusion Or Other Issues In Their Prints.

Print Quality Guide. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. This is very important when 3d. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). The printer failed to provide the amount of plastic required for printing the skipped layers. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. It is easy to upgrade and there is a large community surrounding its use. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems.

Advanced Guide To Printing Petg Filament User Guides : This Article Will Help You To Quickly Diagnose Your 3D Printing Issues, And Find The Solution With Our 3D Printer Troubleshooting Guide.

What Causes Under Extrusion In 3d Printing How To Fix It 3dprintergeeks Com. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The printer failed to provide the amount of plastic required for printing the skipped layers. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. This is very important when 3d. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). It is easy to upgrade and there is a large community surrounding its use.

Common Problems In 3d Printing How To Resolve Them Part I Manufactur3d : Let's Talk About How To Avoid It.

Under Extrusion Problems Or Clicking Sounds Here S Why And How To Fix. This is very important when 3d. The printer failed to provide the amount of plastic required for printing the skipped layers. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. It is easy to upgrade and there is a large community surrounding its use. When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them.

Print Quality Guide . So The Extrusion Width Is Thicker The Better Or Vice Versa??

Troubleshooting Guide To 19 Common 3d Printing Problems Part Two Geeetech Blog. You can see that the extruder motor shaft is vibrating, skipping steps or you can hear a clicking sound during material loading or printing. Problems with extrusion are the most frequent issues you can come across when using an fdm 3d your printer can show extrusion problems in a variety of ways: It is inexpensive and is a good starting printer (as well as a great reliable printer for more advanced users). When printing large objects, you can sometimes run into an issue with the corners of the object being one reply to 7 problems affecting the quality of your 3d prints. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. The printer failed to provide the amount of plastic required for printing the skipped layers. And don't forget that, with a second nozzle and extruder, the possibility of hot end issues is essentially doubled. This article will help you to quickly diagnose your 3d printing issues, and find the solution with our 3d printer troubleshooting guide. The introduction of dual extrusion fdm 3d printers to the market has opened up countless a dual extrusion 3d printer typically costs more than its closest single extrusion counterpart. It is easy to upgrade and there is a large community surrounding its use. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. This is very important when 3d. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. When using a dual extruder 3d printer at some point you may encounter one extruder stopping, while the other extruder deposits the filament.