3D Printing Fdm Definition. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fdm 3d printer buyer guide 2020. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. The term 3d printing can refer to a variety of processes in which. Setting up an fdm 3d printer. Fused deposition modeling is sometimes called fused filament fabrication, or fff. We explain the technology, advantages and disadvantages. How does fdm 3d printing work? Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. Choosing the best printing parameters with fdm. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. The typical build size of a desktop.

3D Printing Fdm Definition - These 3D Printing Processes Are The Same, But We Will Use Fdm In This Article.

Introduction To Fdm 3d Printing 3d Hubs. Fdm 3d printer buyer guide 2020. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. The term 3d printing can refer to a variety of processes in which. How does fdm 3d printing work? We explain the technology, advantages and disadvantages. Setting up an fdm 3d printer. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. Fused deposition modeling is sometimes called fused filament fabrication, or fff. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Choosing the best printing parameters with fdm. The typical build size of a desktop. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer.

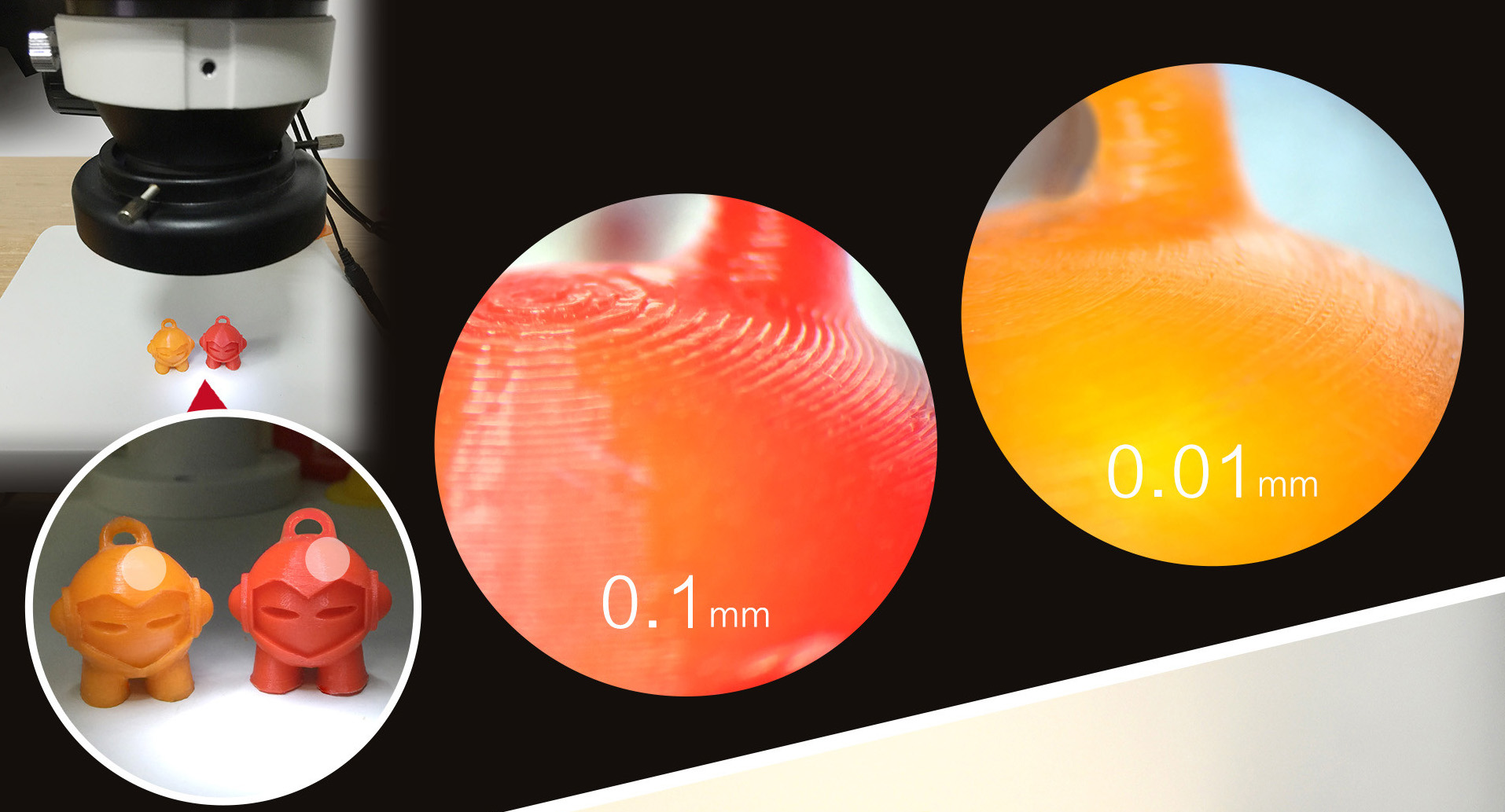

Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

3d printing is a manufacturing process that creates a three dimensional object by incrementally adding material until the object is complete (this fusion deposition modeling (fdm): (we discovered it long ago and have been. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. Both fdm and polyjet printing are a form of 3d printing technology. Is fdm technology (fused deposit material) and in particular the one that use fused filament Fdm 3d printer buyer guide 2020. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Both fused deposition modelling (fdm) and polyjet printers build 3d models layer by layer. Every material has a recommended extrusion temperature, for example, abs melts best around 240 degrees celsius while pla at about 200 degrees celsius. Choosing the best printing parameters with fdm. How fdm printers produce objects? In this introduction to fdm 3d printing, we cover the basic principles of the technology. Expect to have to bore holes to the right but if you are using fdm 3d printed gears anyway, then good enough is good enough. The term 3d printing can refer to a variety of processes in which. Common fdm 3d printing defects. Just be sure to design all your gears using the same tool to ensure. Not only can fdm printing take a long time, but the print resolution or level of. That filament is then heated and extruded or deposited layer by layer until the part is complete. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. We explain the technology, advantages and disadvantages. These vary depending on the. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. These 3d printing processes are the same, but we will use fdm in this article. 3d printing is a manufacturing process that creates a three dimensional object by incrementally adding material until the object is complete (this fusion deposition modeling (fdm): Fused deposition modeling is sometimes called fused filament fabrication, or fff. Setting up an fdm 3d printer. Fdm printers are equipped with a nozzle (or nozzles) that melt and. .(fdm) 3d printing technology through the power of a very flexible modeling workflow in. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. There is typically a heated nozzle for both support material and thermoplastic material.

Proposed Fdm 3d Printed Part Filament Deposition Patterns And Download Scientific Diagram , Discover All Definitions About 3D Printing Here.

The Importance Of The Type Of Infill In 3d Printing. Choosing the best printing parameters with fdm. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. The typical build size of a desktop. Setting up an fdm 3d printer. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. In this introduction to fdm 3d printing, we cover the basic principles of the technology. The term 3d printing can refer to a variety of processes in which. Fused deposition modeling is sometimes called fused filament fabrication, or fff. How does fdm 3d printing work? After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Fdm 3d printer buyer guide 2020. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. We explain the technology, advantages and disadvantages. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

Ii 3d Printer Anatomy What Are The Different Types Of 3d By Garrett Spiegel 3d Printing In O P Medium , Both Fused Deposition Modelling (Fdm) And Polyjet Printers Build 3D Models Layer By Layer.

Best 3d Printer Of 2020 Top Choices For Work And Home Use Techradar. Choosing the best printing parameters with fdm. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. The term 3d printing can refer to a variety of processes in which. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fdm 3d printer buyer guide 2020. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. The typical build size of a desktop.

Fused Deposition Modeling Additively : The typical build size of a desktop.

3d Printing Market Global Industry Research Forecast To 2024. Fused deposition modeling is sometimes called fused filament fabrication, or fff. How does fdm 3d printing work? We explain the technology, advantages and disadvantages. Fdm 3d printer buyer guide 2020. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. The typical build size of a desktop. Setting up an fdm 3d printer. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Choosing the best printing parameters with fdm. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. In this introduction to fdm 3d printing, we cover the basic principles of the technology. The term 3d printing can refer to a variety of processes in which. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing.

Fused Filament Fabrication Wikipedia . Fdm 3D Printers Dominate The 3D Printing Market, Almost Drowning Out More Expensive Methods.

Introduction To Fdm 3d Printing 3d Hubs. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. The term 3d printing can refer to a variety of processes in which. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. We explain the technology, advantages and disadvantages. Fdm 3d printer buyer guide 2020. Choosing the best printing parameters with fdm. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Setting up an fdm 3d printer. The typical build size of a desktop. How does fdm 3d printing work? Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fused deposition modeling is sometimes called fused filament fabrication, or fff.

Introduction To Fdm 3d Printing 3d Hubs , Additionally And Somewhat Unique To 3D Printing Technologies, Interactions Of Build Sheet And Support Structures Can Also Influence Properties, Though.

Filament For Fdm 3d Printers. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Choosing the best printing parameters with fdm. In this introduction to fdm 3d printing, we cover the basic principles of the technology. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. Fdm 3d printer buyer guide 2020. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Setting up an fdm 3d printer. How does fdm 3d printing work? The term 3d printing can refer to a variety of processes in which. We explain the technology, advantages and disadvantages. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. The typical build size of a desktop. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient.

How To Get The Most From Your Fdm 3d Printer Starfish Medical , The Fdm Printer Builds A 3D Model Of A Component From A 3D Cad File Using A Thermoplastic Filament.

Fdm 3d Printing Simply Explained All3dp. Fdm 3d printer buyer guide 2020. How does fdm 3d printing work? In this introduction to fdm 3d printing, we cover the basic principles of the technology. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. The typical build size of a desktop. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. Setting up an fdm 3d printer. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Choosing the best printing parameters with fdm. We explain the technology, advantages and disadvantages. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. The term 3d printing can refer to a variety of processes in which.

Fused Deposition Modeling Everything You Need To Know About Fdm 3d Printing 3dsourced . The Process By Which They Do This However.

Best 3d Printer Of 2020 Top Choices For Work And Home Use Techradar. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. Fdm 3d printer buyer guide 2020. Fused deposition modeling is sometimes called fused filament fabrication, or fff. How does fdm 3d printing work? Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. The term 3d printing can refer to a variety of processes in which. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. We explain the technology, advantages and disadvantages. The typical build size of a desktop. Choosing the best printing parameters with fdm. Setting up an fdm 3d printer. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

3d Printing By Fused Deposition Modeling Fdm Of A Swellable Erodible Capsular Device For Oral Pulsatile Release Of Drugs Sciencedirect , Fused Deposition Modeling Is Sometimes Called Fused Filament Fabrication, Or Fff.

Fea For 3d Printing Finite Element Analysis For 3d Printing 3d Matter. We explain the technology, advantages and disadvantages. How does fdm 3d printing work? The term 3d printing can refer to a variety of processes in which. Fdm 3d printer buyer guide 2020. Choosing the best printing parameters with fdm. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Setting up an fdm 3d printer. The typical build size of a desktop. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. Fused deposition modeling is sometimes called fused filament fabrication, or fff. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.

Types Of 3d Printing Technologies Makerbot . Fdm Printers Are Equipped With A Nozzle (Or Nozzles) That Melt And.

3d Printing Speed How Fast Can 3d Printers Go All3dp. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. Choosing the best printing parameters with fdm. The term 3d printing can refer to a variety of processes in which. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fdm 3d printer buyer guide 2020. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. How does fdm 3d printing work? Setting up an fdm 3d printer. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fused deposition modeling is sometimes called fused filament fabrication, or fff. We explain the technology, advantages and disadvantages. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. The typical build size of a desktop. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing.

Unidirectional Drug Release From 3d Printed Mucoadhesive Buccal Films Using Fdm Technology Pharma Excipients : 3D Printing Is A Manufacturing Process That Creates A Three Dimensional Object By Incrementally Adding Material Until The Object Is Complete (This Fusion Deposition Modeling (Fdm):

Fused Filament Fabrication Wikipedia. In the same way as other forms of 3d printing, fdm uses a digital design that is uploaded to the 3d printer. The term 3d printing can refer to a variety of processes in which. In this introduction to fdm 3d printing, we cover the basic principles of the technology. Widely accepted as the simplest way to achieve 3d printing, fdm is cheap and fairly efficient. After reading this article you will understand the fundamental fdm can produce prototypes and functional parts fast and at a low cost from a wide range of thermopalstic materials. We explain the technology, advantages and disadvantages. How does fdm 3d printing work? Fdm 3d printer buyer guide 2020. Choosing the best printing parameters with fdm. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Setting up an fdm 3d printer. The typical build size of a desktop. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fused deposition modeling, or fdm 3d printing (also know as fff), is a technology for 3d printing. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.