3D Printing For Manufacturing Process. Different techniques, processes and technologies. The technology is enabling engineers to innovate the design of rocket parts. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Each of these layers can be seen as a. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. A number of different 3d printing technologies exist and are universally available. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Some are preferable for rapid prototyping during the development.

3D Printing For Manufacturing Process , The Term 3D Printing Is Increasingly Used As A Synonym For Additive Manufacturing.

Automotive 3d Printing Market Size Share Analysis Report 2023. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Some are preferable for rapid prototyping during the development. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. A number of different 3d printing technologies exist and are universally available. Each of these layers can be seen as a. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. The technology is enabling engineers to innovate the design of rocket parts. Different techniques, processes and technologies. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance.

Plus, the process is quite easy to integrate into existing manufacturing or foundry processes without disruption.

3d printing for prototyping and manufacturing. The technology is enabling engineers to innovate the design of rocket parts. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing for prototyping and manufacturing. The final object is created by adding a layer of material on top of each other (by opposition resin 3d printers using the sla or dlp technologies are based on the photopolymerization process: 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it 3d printing is part of a family of manufacturing technology called additive manufacturing. A number of different 3d printing technologies exist and are universally available. Traditional manufacturing processes like forming and injection molding are more suitable for large scale manufacture, whereas 3d printing may be. Production 3d printing shortcuts that process. Plus, the process is quite easy to integrate into existing manufacturing or foundry processes without disruption. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Modeling and simulation of functionalized materials for additive manufacturing and 3d printing: Continuum and discrete element methods. The specific chemical types and forms of the polymer materials that are used in each process are identified later in this guide. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The resin contained in the 3d printer tank is cured. Though it's a very contained process, it's also transparent — users can. Print materials made of plastics and polymers are defined by the parameters of. Additive manufacturing is also used to. 7 tips to start small scale manufacturing | business ideas for product makers. When the model design is already finalized, the capabilities of each 3d printing technology will often play the main role in the process selection. 3d printing is an additive manufacturing (am) technique: 3d printing and additive manufacturing. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Let's break it down further. Injection molding is a manufacturing process used for producing products in large volumes. Material extrusion is a 3d printing process where a filament of solid thermoplastic material is pushed through a heated nozzle, melting it in the process. It is important to have an overview of the fundamental mechanics of each process to fully understand. This contrasts with traditional manufacturing processes that either mold 3d printing is a manufacturing process that creates objects by laying down successive layers of material. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Overview Over 3d Printing Technologies Additively - 3D Printing And Additive Manufacturing.

Infographic The Power Of 3d Printing In Manufacturing. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Each of these layers can be seen as a. Different techniques, processes and technologies. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. A number of different 3d printing technologies exist and are universally available. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Some are preferable for rapid prototyping during the development. The technology is enabling engineers to innovate the design of rocket parts. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets.

Optimizing Production Processes With 3d Printing Formlabs : The Resin Contained In The 3D Printer Tank Is Cured.

New 3d Manufacturing Process Materialising Micro Lattice Structures Lattice Structure 3d Printing Industry Manufacturing Process. A number of different 3d printing technologies exist and are universally available. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. The technology is enabling engineers to innovate the design of rocket parts. Some are preferable for rapid prototyping during the development. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. Each of these layers can be seen as a. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in.

Using 3d Printing In Product Design And Development Deloitte Insights . Injection molding is a manufacturing process used for producing products in large volumes.

What Is Laminated Object Manufacturing 3d Printing Live Science. Each of these layers can be seen as a. The technology is enabling engineers to innovate the design of rocket parts. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. Some are preferable for rapid prototyping during the development. A number of different 3d printing technologies exist and are universally available. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Different techniques, processes and technologies. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

3d Printing And Additive Manufacturing Concept Vector Image : The Technology Is Enabling Engineers To Innovate The Design Of Rocket Parts.

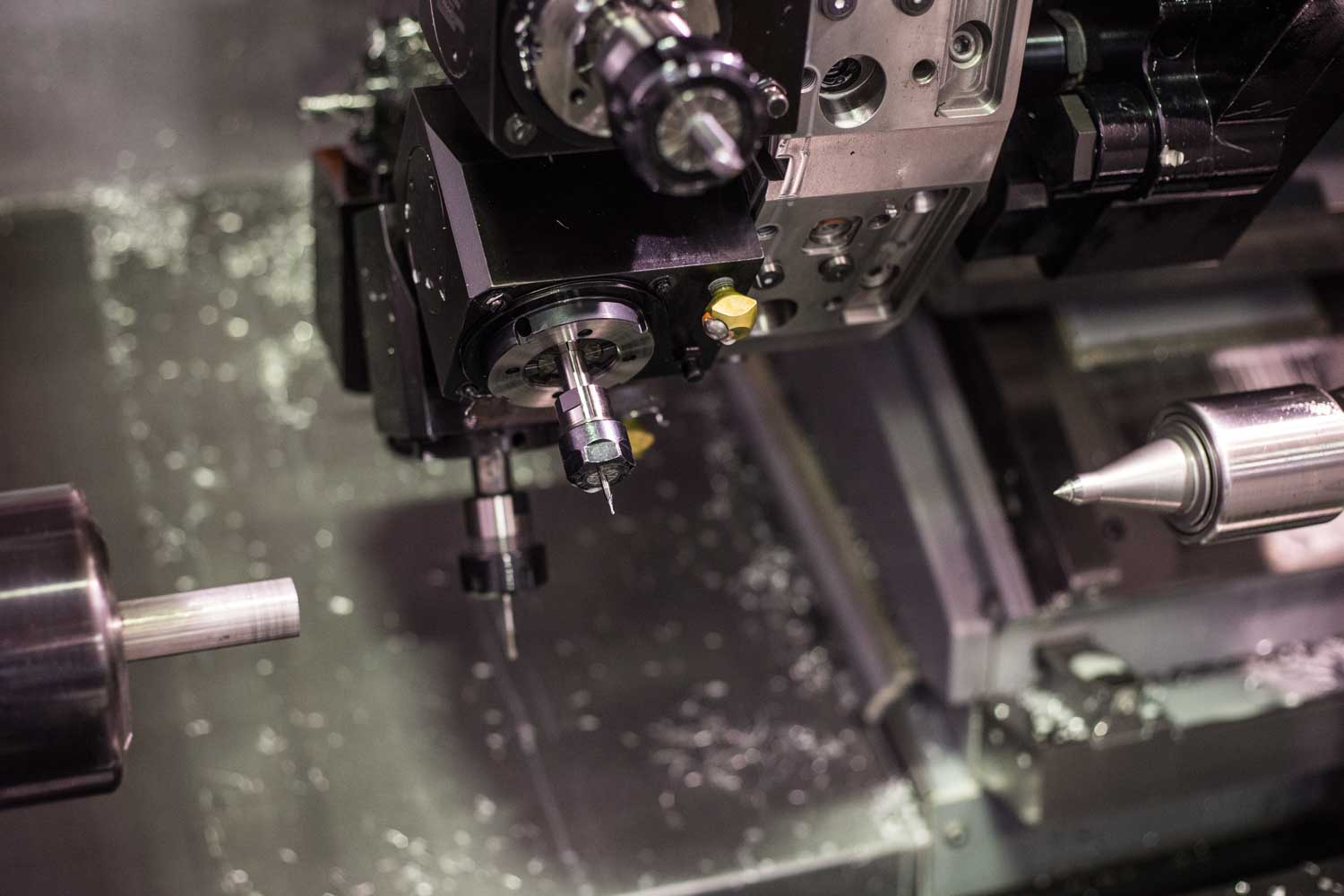

Metal 3d Printing The Manufacturing Design Guide 3d Hubs. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. A number of different 3d printing technologies exist and are universally available. Different techniques, processes and technologies. Some are preferable for rapid prototyping during the development. Each of these layers can be seen as a. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology is enabling engineers to innovate the design of rocket parts. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed.

Trends In Industrial Additive Manufacturing 3d Printing Plant Automation Technology : Currently, Design And Rapid Prototyping Are Two Of The Main Processes That Benefit From 3D Prints.

Marks Clerk 3d Printing. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Some are preferable for rapid prototyping during the development. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Different techniques, processes and technologies. A number of different 3d printing technologies exist and are universally available. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. The technology is enabling engineers to innovate the design of rocket parts. Each of these layers can be seen as a.

New 3d Manufacturing Process Materialising Micro Lattice Structures Lattice Structure 3d Printing Industry Manufacturing Process : The Resin Contained In The 3D Printer Tank Is Cured.

Deloitte 3d Opportunity Figure 1 Breakeven Analysis Comparing Conventional And Additive Manufact Deloitte University 3d Printing Paper Manufacturing Process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Some are preferable for rapid prototyping during the development. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. The technology is enabling engineers to innovate the design of rocket parts. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. Each of these layers can be seen as a. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Different techniques, processes and technologies. A number of different 3d printing technologies exist and are universally available.

Factors To Consider When 3d Printing Or Additive Manufacturing Metal Parts Engineering360 , Print Materials Made Of Plastics And Polymers Are Defined By The Parameters Of.

Best 3d Printing Report. Different techniques, processes and technologies. A number of different 3d printing technologies exist and are universally available. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Some are preferable for rapid prototyping during the development. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. The technology is enabling engineers to innovate the design of rocket parts. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. Each of these layers can be seen as a. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets.

Augmentation Of The Ontology Of The 3d Printing Research Leaders In Pharmaceutical Business Intelligence Lpbi Group . Physicians Can Print Physical Models Of Portions Of Patient Anatomy To Better Visualize Procedures And Demonstrate Practice.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing. Some are preferable for rapid prototyping during the development. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. The technology is enabling engineers to innovate the design of rocket parts. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Different techniques, processes and technologies. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. Each of these layers can be seen as a. A number of different 3d printing technologies exist and are universally available. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture.

Introduction To Fdm 3d Printing 3d Hubs . A Number Of Different 3D Printing Technologies Exist And Are Universally Available.

Additive Manufacturing With 3d Printing Progress From Bench To Bedside Pharma Excipients. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Different techniques, processes and technologies. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The technology is enabling engineers to innovate the design of rocket parts. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. A number of different 3d printing technologies exist and are universally available. Each of these layers can be seen as a. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints. Some are preferable for rapid prototyping during the development.

Automated 3d Printing How Industrial Additive Manufacturing Is Evolving Engineering Com - The Specific Chemical Types And Forms Of The Polymer Materials That Are Used In Each Process Are Identified Later In This Guide.

Optimizing Production Processes With 3d Printing Formlabs. Some are preferable for rapid prototyping during the development. Each of these layers can be seen as a. 3d printing already plays several roles in the manufacturing process, and it is poised to make further gains as it is refined and perfected. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. A number of different 3d printing technologies exist and are universally available. Additive manufacturing is a generic term that was used to describe the manufacturing process like 3d printer. Different techniques, processes and technologies. 3d printing, particularly with metals, is increasingly being used in the manufacture of rockets. In the future, printing material modifications by compounding processes have to be taken into account for optimized functional performance. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology is enabling engineers to innovate the design of rocket parts. The creation of a 3d printed object is in an additive process an object is created by laying down successive layers of material until the object is created. Currently, design and rapid prototyping are two of the main processes that benefit from 3d prints.