3D Printing For Prosthetics. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. According to a statement made by the american orthotics and prosthetics association, the average. 3d printed prosthetic hand via thingverse. 3d printed prosthetics can greatly benefit children. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. In fact, you will be amazed even if you do not wear a prosthetic limb. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with.

3D Printing For Prosthetics : Limbforge Is An Association That Aims To Provide Prostheses To Developing Countries That Can Not Often Afford These Medical Devices.

3ders Org Unyq S 3d Printed Covers Make Prosthetics Modern And Stylish 3d Printer News 3d Printing News 3d Printing 3d Printing News Medical Design. In fact, you will be amazed even if you do not wear a prosthetic limb. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetic hand via thingverse. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. 3d printed prosthetics can greatly benefit children. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. According to a statement made by the american orthotics and prosthetics association, the average. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics.

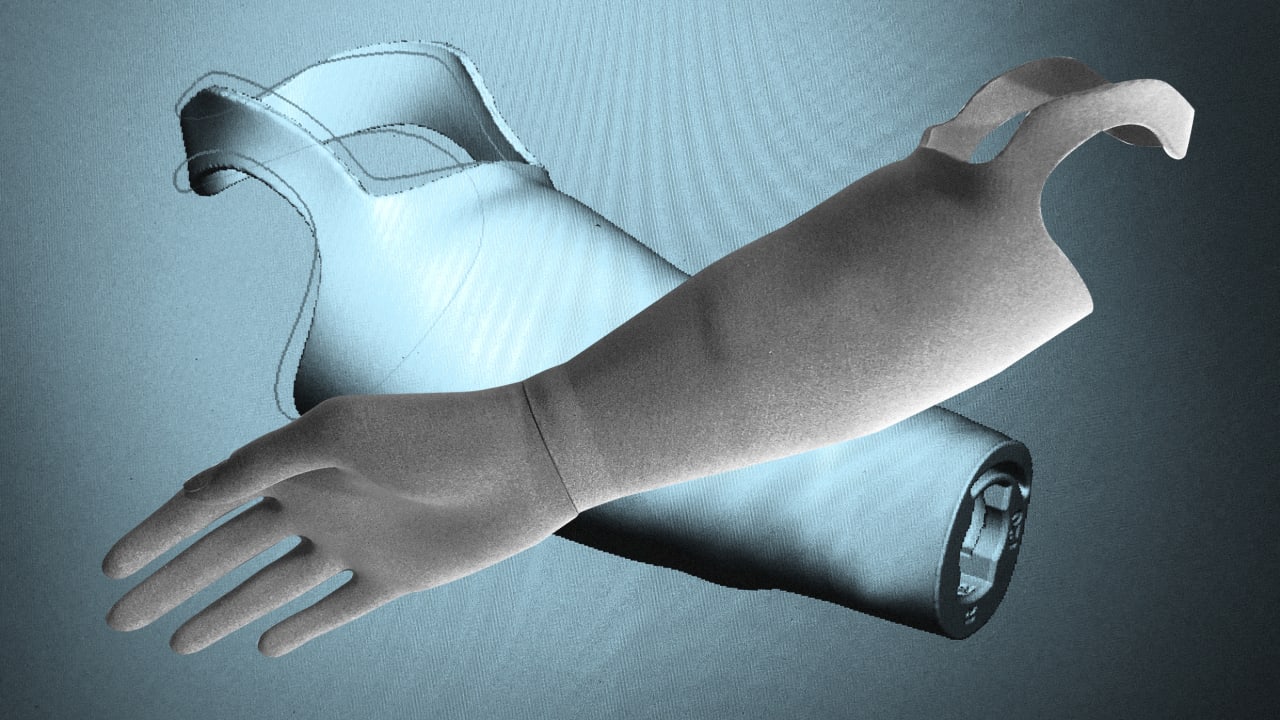

A slide from a talk by industrial designer scott summit showcases what is now possible in prosthetics using 3d printing.

While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. The top countries of supplier is china, from. In fact, you will be amazed even if you do not wear a prosthetic limb. Traditional prosthetics can cost tens of thousands of dollars, making them inaccessible to many. There are more than 10 million amputees around. See more ideas about prosthetics, prosthetic leg, 3d printing projects. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. Produce end products each with unique and customized designs 3. Choose from a compact or medium size and with standard or advanced features to fit your operation build large industrial prints with high precision and quality with the funmat pro 3d printer. It is the purpose of this guide to highlight the present and future benefits of medical 3d printing for humans. According to a statement made by the american orthotics and prosthetics association, the average. 3d printed prosthetic hand via thingverse. This makes 3d printed prosthetics for children a perfect solution. Conventional maxillofacial prosthetics are incredibly laborious and expensive to produce, says fripp. 3d printing changing prosthetics forever. 3d printed prosthetics are substantially cheaper than traditionally made prosthetics. It is capable of running two colors, and two different materials at the same time. A 3d prosthetic being printed in the dell technologies world solutions expo. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership the but the time and cost are minimal compared to a traditional prosthetic. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. This is mirrored and used as. For the makers of prosthetics this means you can print the bone structures and skin at the same time, and it uses only one extruder. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. For industrial designer scott summit, the ability to make perfectly fitted, custom prosthetics is a major goal. How 3d printing is making prosthetics cheap and accessible, even in remote places. 831 3d printing for prosthetics products are offered for sale by suppliers on alibaba.com, of which machining accounts for 1%, digital printers accounts there are 36 suppliers who sells 3d printing for prosthetics on alibaba.com, mainly located in asia. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. We can now print anything from dental applications to customizable, prosthetics. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Enable community foundation is an organization pairing.

3d Printed Prosthetics The New Revolution 3dincredible , 3D Printed Prosthetics Literally Grow With You.

The Future Is Here 3d Printed Prosthetics. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. 3d printed prosthetic hand via thingverse. According to a statement made by the american orthotics and prosthetics association, the average. In fact, you will be amazed even if you do not wear a prosthetic limb. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. 3d printed prosthetics can greatly benefit children.

Titanium Prosthetic Limbs Can Now Be 3d Printed You Go Science The American Genius : While Prosthetic Devices Have Continued To Advance Throughout History, 3D Printing Technology Has Emerged As A Revolutionary Way To Enhance This Medical Device By Avoiding The Traditional Negative Impacts That Are Often Associated With Modern Prosthetics.

Titanium Prosthetic Limbs Can Now Be 3d Printed You Go Science The American Genius. According to a statement made by the american orthotics and prosthetics association, the average. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. 3d printed prosthetic hand via thingverse. 3d printed prosthetics can greatly benefit children. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Right now the field of 3d printed prosthetics is young, and many devices are prototypes.

3d Printed Prosthetics 8 Incredible Animal Prostheses : Conventional maxillofacial prosthetics are incredibly laborious and expensive to produce, says fripp.

3d Printed Prosthetics Where We Are Today Amputee Coalition. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. In fact, you will be amazed even if you do not wear a prosthetic limb. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. According to a statement made by the american orthotics and prosthetics association, the average. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. 3d printed prosthetics can greatly benefit children. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. 3d printed prosthetic hand via thingverse.

3d Printing For Prosthetics Raise3d , The Affordability Of 3D Printers And The Ability For Anyone To Design And Print Custom Design Parts Has Made Prosthetics Radically More Affordable And Accessible To People All.

3d Printed Prosthetics Cut Costs In Uganda. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. According to a statement made by the american orthotics and prosthetics association, the average. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetic hand via thingverse. 3d printed prosthetics can greatly benefit children. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. In fact, you will be amazed even if you do not wear a prosthetic limb.

Cap Project Launches To Bring 3d Printed Prosthetics To Animals Looking For Volunteers Open Biomedical Initiative We Help , This Makes 3D Printed Prosthetics For Children A Perfect Solution.

Changing Lives With Printed Prosthetics The Star. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. According to a statement made by the american orthotics and prosthetics association, the average. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. 3d printed prosthetic hand via thingverse. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. In fact, you will be amazed even if you do not wear a prosthetic limb. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. 3d printed prosthetics can greatly benefit children.

Unyq Launches New Collection Of 3d Printed Prosthetic Covers 3printr Com , 3D Printed Prosthetic Hand Via Thingverse.

Lifenabled Makes Cheap 3d Printed Prosthetics In Guatemala. According to a statement made by the american orthotics and prosthetics association, the average. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. 3d printed prosthetics can greatly benefit children. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. 3d printed prosthetic hand via thingverse. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. In fact, you will be amazed even if you do not wear a prosthetic limb.

Top 15 Prosthetics Made With 3d Printing Bitfab . Print In Technical Polymers Like Peek, Pei And More.

3d Printed Prosthetic Hands No Category Talk Manufacturing 3d Hubs. 3d printed prosthetics can greatly benefit children. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetic hand via thingverse. According to a statement made by the american orthotics and prosthetics association, the average. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. In fact, you will be amazed even if you do not wear a prosthetic limb. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics.

Top 15 Prosthetics Made With 3d Printing Bitfab - This Makes 3D Printed Prosthetics For Children A Perfect Solution.

The Most Common 3d Printed Prosthetics All3dp. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. According to a statement made by the american orthotics and prosthetics association, the average. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. 3d printed prosthetics can greatly benefit children. 3d printed prosthetic hand via thingverse. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. In fact, you will be amazed even if you do not wear a prosthetic limb. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with.

3d Printing A Prosthetic In 2 Weeks 3d Printing Industry - 3D Printed Prosthetics Are Substantially Cheaper Than Traditionally Made Prosthetics.

The 3d Printed Prosthetic Thumb And A Real Human Thumb Download Scientific Diagram. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. 3d printed prosthetics can greatly benefit children. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. 3d printed prosthetic hand via thingverse. In fact, you will be amazed even if you do not wear a prosthetic limb. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. According to a statement made by the american orthotics and prosthetics association, the average. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs.

Medical 3d Printing Applications For Prosthetics Implants More - Could We One Day 3D Print Replacement Organs And Parts For Own Our Bodies?

How 3d Printing Is Transforming Lives With Better Fitting And Better Looking Prosthetics. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Currently, prosthetists use 3d printing to create prosthetic hands, arms, feet, and legs. The average lifespan of a prosthetic is five years, but in that time a child grows so rapidly that they will need a new prosthetic much more frequently. What started as a diy movement for people to be empowered to make their own prosthetic hands is now influencing how. If you are one of the millions of physically unique individuals around the world that require the use of a prosthetic limb, prepare to be amazed. 3d printed prosthetic hand via thingverse. Right now the field of 3d printed prosthetics is young, and many devices are prototypes. In fact, you will be amazed even if you do not wear a prosthetic limb. The affordability of 3d printers and the ability for anyone to design and print custom design parts has made prosthetics radically more affordable and accessible to people all. 3d printed prosthetics can greatly benefit children. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are marked with. Limbforge is an association that aims to provide prostheses to developing countries that can not often afford these medical devices. Moreover, prosthetics need to be custom fit to the individual, requiring a production time on the order of weeks or months. According to a statement made by the american orthotics and prosthetics association, the average. Traditional prosthetics can cost thousands of dollars and need to be replaced as children grow.