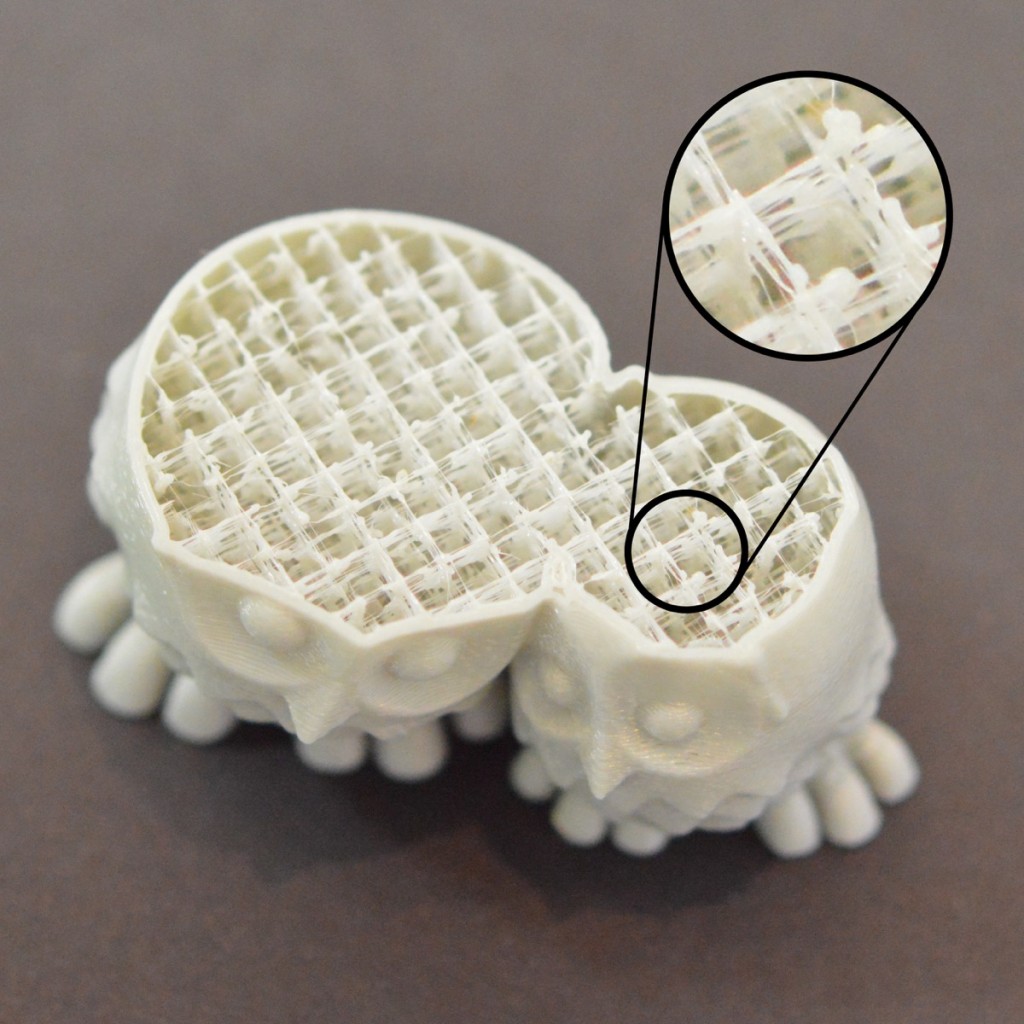

3D Printing Infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. If strength is critical to the function of a 3d printed part. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. What is infill in 3d printing? It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Consider a print with low infill that is going to be drilled and then screwed to another surface. Once you know what your print is going to be used for. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer.

3D Printing Infill . This Means Your Printer Will Print 10 Solid Perimeters Before Attempting To Place Any Infill.

Infill Settings Ultimaker Support. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Consider a print with low infill that is going to be drilled and then screwed to another surface. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. If strength is critical to the function of a 3d printed part. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. What is infill in 3d printing? This shape is the most efficient infill and fastest to print, the goto infill for most things. All3dp is an editorially independent publication. Best infill for strength vs material used. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to.

Every day new 3d models from all over the world.

Every day new 3d models from all over the world. Print with dual multiple extruders. Once you know what your print is going to be used for. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Triangular infill is the strongest infill pattern because triangles are the strongest shape. I'm working on printing parts for a maker select v2 rebuild i designed, but i've noticed an excessive amount of ringing on my prints, mostly due to what would be the best infill pattern for structural parts? Gaps between the outline of the part and the outer solid infill layers. Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like: When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Use brim for the best adhesion. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Basically the final 3d printed model will have different infill densities depending on the region of the model. What is infill in 3d printing? This unique feature improves built plate adhesion by generating a base flange around your. The infill lines usually print at a 45° angle. Print beautiful colored objects, or use your secondary extruder to build support material. Printing at the fastest possible setting. They are least likely to deform and provide the best support structure behind the walls of the strength and the speed combined makes triangular infill one of the best choices for infill in 3d printing. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece. Findings from this study will help formulate criteria for selection of optimal infill design based on loading conditions and cost of printing. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. The printer will still ooze a little bit of. If you are using a.4mm nozzle, that will result in 4mm thickness. This shape is the most efficient infill and fastest to print, the goto infill for most things. If strength is critical to the function of a 3d printed part. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Every day new 3d models from all over the world. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Best infill for strength vs material used.

3d Printing A 3d Honeycomb Infill Concept Engineerdog . Normally, Rolling Programs Allow The Percentage Of Material To Be Modified From 0% (Hollow Part) To 100% (Totally Solid Part).

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcrhsqzwoojjqnijlnx Vjwc7nydn9bqb1teeg Usqp Cau. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Best infill for strength vs material used. If strength is critical to the function of a 3d printed part. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? Consider a print with low infill that is going to be drilled and then screwed to another surface.

Researchers Develop Infill Algorithm For Stronger Faster Fdm 3d Prints 3d Printing Industry - Sometimes All You Need Is A Visual Aid To Make Things Click. My Favorite Of His Tools Is The Infill Percent Display, Which Is Entirely 3D Printable And It Displays All Of The.

Particular Batch Of 3d Printed Specimens With Various 3d Infill Types Download Scientific Diagram. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Consider a print with low infill that is going to be drilled and then screwed to another surface. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. If strength is critical to the function of a 3d printed part. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. All3dp is an editorially independent publication.

Gaps In The Infill Ultimaker Cura Ultimaker Community Of 3d Printing Experts . Editorial content, on principle, can not be bought or influenced.

How Much Does 3d Printing Cost Additive3d Asia. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Consider a print with low infill that is going to be drilled and then screwed to another surface. Infill provides the 3d print with internal support as the printer builds each layer. This shape is the most efficient infill and fastest to print, the goto infill for most things. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. If strength is critical to the function of a 3d printed part. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used.

How To Strengthen 3d Printed Parts In 5 Simple Ways Manufactur3d , There Are A Lot Of Concepts Within The Desktop 3D Printing Space Which Sometimes Are A Bit Complicated To Understand.

Intro To 3d Printing Infill Percentage Number Of Shells Layer Height Part Orientation 3d Printing Diy Prints 3d Printing. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. Infill percentage in 3d printing. What is infill in 3d printing? Editorial content, on principle, can not be bought or influenced. Best infill for strength vs material used. This shape is the most efficient infill and fastest to print, the goto infill for most things. Once you know what your print is going to be used for. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. If strength is critical to the function of a 3d printed part. All3dp is an editorially independent publication. Consider a print with low infill that is going to be drilled and then screwed to another surface.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros - It Will Save You Material Much Of 3D Printing Is Really Structure And Design And I Feel That Having Some Knowledge In Why Nature Does What It Does Will Add Some Forethought To.

Gaps Between Infill And Outline. Once you know what your print is going to be used for. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Consider a print with low infill that is going to be drilled and then screwed to another surface. This shape is the most efficient infill and fastest to print, the goto infill for most things. If strength is critical to the function of a 3d printed part. All3dp is an editorially independent publication. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. Editorial content, on principle, can not be bought or influenced. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

3d Printing Internal Geometry An Often Overlooked Critical Design Detail , Use Brim For The Best Adhesion.

How To Use 3d Print Infill Settings Increase Strength Save Filament. Consider a print with low infill that is going to be drilled and then screwed to another surface. Best infill for strength vs material used. Editorial content, on principle, can not be bought or influenced. Infill provides the 3d print with internal support as the printer builds each layer. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill percentage in 3d printing. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. If strength is critical to the function of a 3d printed part. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for. What is infill in 3d printing? This shape is the most efficient infill and fastest to print, the goto infill for most things.

Frayed Infill New Mk3 3dprinting - This Guide Is A Great Place To Start If You Are Trying To Improve The Quality Of Your 3D Printed Parts.

Gradient Infill New Efficient Infill For 3d Prints Youtube. What is infill in 3d printing? Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. This shape is the most efficient infill and fastest to print, the goto infill for most things. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. If strength is critical to the function of a 3d printed part. Consider a print with low infill that is going to be drilled and then screwed to another surface. All3dp is an editorially independent publication. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for. Editorial content, on principle, can not be bought or influenced.

Gaps Between Infill And Outline : What Is Infill In 3D Printing?

Kronr United States 3d Artist Pinshape. Best infill for strength vs material used. Infill provides the 3d print with internal support as the printer builds each layer. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. If strength is critical to the function of a 3d printed part. Consider a print with low infill that is going to be drilled and then screwed to another surface. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. What is infill in 3d printing?

Gradient Infill New Efficient Infill For 3d Prints Youtube . I'm Working On Printing Parts For A Maker Select V2 Rebuild I Designed, But I'vE Noticed An Excessive Amount Of Ringing On My Prints, Mostly Due To What Would Be The Best Infill Pattern For Structural Parts?

3d Printing A 3d Honeycomb Infill Concept Engineerdog. Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Consider a print with low infill that is going to be drilled and then screwed to another surface. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Once you know what your print is going to be used for. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. If strength is critical to the function of a 3d printed part. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

What Causes This Bad Infill 3dprinting , Sometimes All You Need Is A Visual Aid To Make Things Click. My Favorite Of His Tools Is The Infill Percent Display, Which Is Entirely 3D Printable And It Displays All Of The.

Gaps Between Infill And Outline. Consider a print with low infill that is going to be drilled and then screwed to another surface. Infill percentage in 3d printing. What is infill in 3d printing? All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Best infill for strength vs material used. Infill provides the 3d print with internal support as the printer builds each layer. If strength is critical to the function of a 3d printed part. This shape is the most efficient infill and fastest to print, the goto infill for most things. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to.