3D Printing Infill Density. This allows it to print. In s3d it's a little bit different, we. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The density of your infill makes a huge difference in the weight and durability of your print. For example, what does a 40% infill density look like compared to a 70% infill? Infill density the infill density defines the amount of plastic used on the inside of the print. Editorial content, on principle, can not be bought or influenced. Basically the final 3d printed model will have different infill densities depending on the region of the model. There is too much superficial knowledge. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. All3dp is an editorially independent publication. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities.

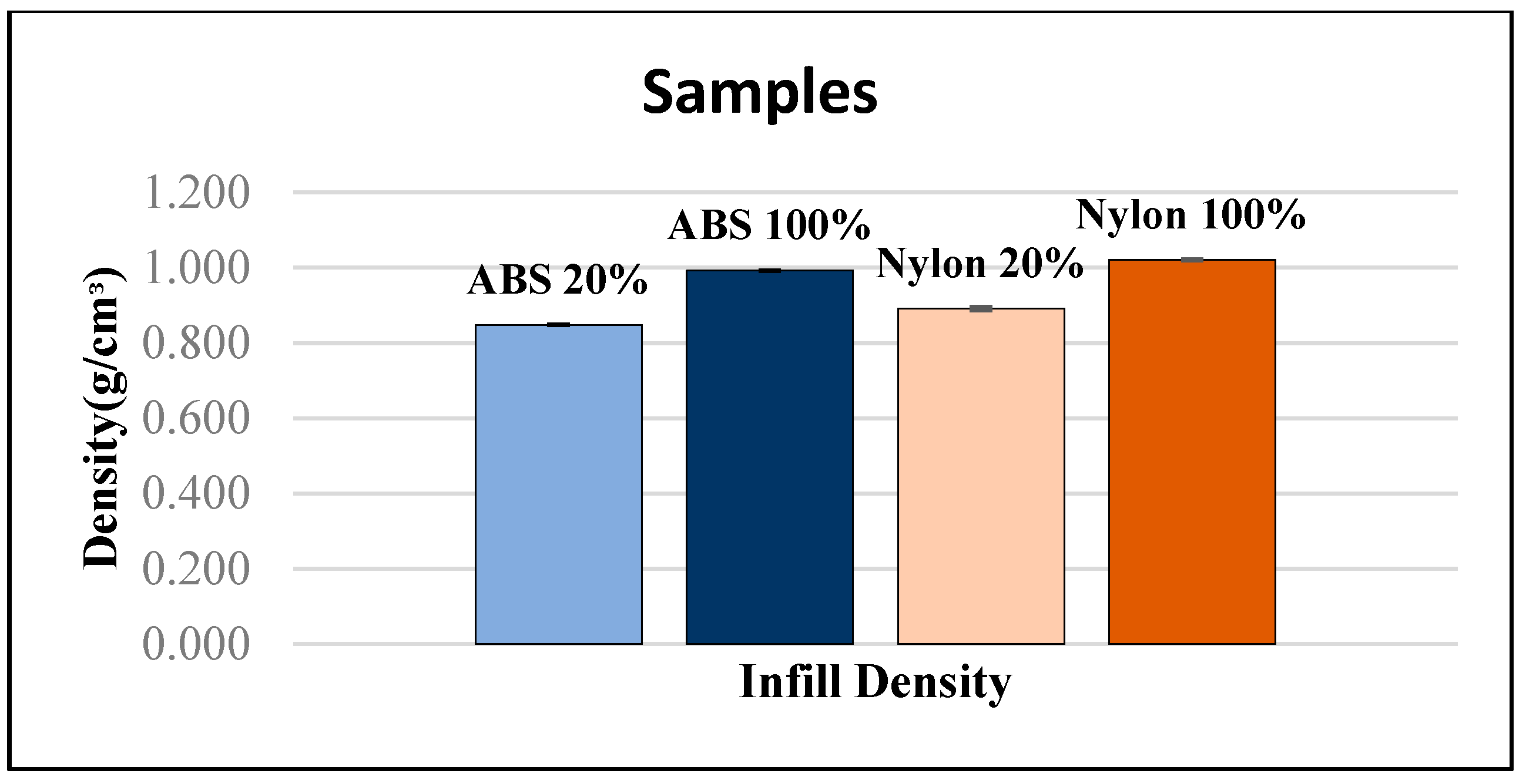

3D Printing Infill Density , Significant Increasing, Which Requires A Higher Cost.

How To Choose An Infill For Your 3d Prints. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill density the infill density defines the amount of plastic used on the inside of the print. In s3d it's a little bit different, we. All3dp is an editorially independent publication. There is too much superficial knowledge. This allows it to print. Editorial content, on principle, can not be bought or influenced. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. Basically the final 3d printed model will have different infill densities depending on the region of the model. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. The density of your infill makes a huge difference in the weight and durability of your print. For example, what does a 40% infill density look like compared to a 70% infill? Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print.

Basically the final 3d printed model will have different infill densities depending on the region of the model.

I am a hands on learner so i wanted sample trays that i could physically hold and look at to decide which infill to use. 3d printer pla filament 1.75mm, labists plastic 3d printing pla filament bundle 1kg/2.2lb,.25kg/spool 4 colors (white, red, black, blue). Basically the final 3d printed model will have different infill densities depending on the region of the model. A higher infill density means that there. The density of your infill makes a huge difference in the weight and durability of your print. This infill uses the most material but offers the highest density; Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. 6% before printing, make sure that the hotend is clean, as leftover material in the part can damage. The specific infill pattern you use will have a huge effect on the strength of the finished part. If the infill is looking week then decrease the infill print speed. All3dp is an editorially independent publication. Triangular infill is the strongest infill pattern because triangles are the strongest shape. The higher your infill percentage, the stronger your part. Increasing the infill density the time spent on printing is. Infill takes up the empty space within a 3d print to reinforce and increase the the higher the density is, the more structurally sound your 3d print is going to be. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. The infill the amount of material that occupies the internal part of the piece. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. Critical variable in estimating the cost of 3d printing. Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. There is too much superficial knowledge. I saw similar designs already out there but i wasn't completely satisfied with them so i designed my own. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to your creations. We provide high quality pla filament, abs filament, petg filament and many more speciality filaments. Part strength ensures that the printed part is strong and durable during the use or storage which will for hollowed parts, the most obvious way to increase the strength is to increase the infill density. Better thin walls (anchored inside the print, no more random bits at the ends, embedded in combine infill every 'n' perimeters layer & varying density to speed up printing. Multiple layer heights in a. We also provide micro swiss & magigoo products. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced effectiveness of the additional material used. 3d printing infill is the secret to stronger and more stable 3d prints. Best infill for strength vs material used.

These 3d Printable Tools Help You Understand Infill Percentages Number Of Shells And More 3dprint Com The Voice Of 3d Printing Additive Manufacturing . The Amount Of These Structures Is Called Infill Density, This Parameter Being One Of The Adjustments To Be Provided To The Slicer.

These 3d Printable Tools Help You Understand Infill Percentages Number Of Shells And More 3dprint Com The Voice Of 3d Printing Additive Manufacturing. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The density of your infill makes a huge difference in the weight and durability of your print. Editorial content, on principle, can not be bought or influenced. In s3d it's a little bit different, we. For example, what does a 40% infill density look like compared to a 70% infill? The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. There is too much superficial knowledge. Infill density the infill density defines the amount of plastic used on the inside of the print. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Basically the final 3d printed model will have different infill densities depending on the region of the model. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. This allows it to print.

These 3d Printable Tools Help You Understand Infill Percentages Number Of Shells And More 3dprint Com The Voice Of 3d Printing Additive Manufacturing - 3D Printing Infill Is The Secret To Stronger And More Stable 3D Prints.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. There is too much superficial knowledge. The density of your infill makes a huge difference in the weight and durability of your print. Editorial content, on principle, can not be bought or influenced. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill density the infill density defines the amount of plastic used on the inside of the print. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. In s3d it's a little bit different, we.

Infill And Strength Functional Design Doesn T Stop At The Cad Desk 3d Printing For Beginners , I saw similar designs already out there but i wasn't completely satisfied with them so i designed my own.

3d Print Infill Density Grabcad Tutorials. For example, what does a 40% infill density look like compared to a 70% infill? There is too much superficial knowledge. The density of your infill makes a huge difference in the weight and durability of your print. In s3d it's a little bit different, we. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. Basically the final 3d printed model will have different infill densities depending on the region of the model. This allows it to print. Infill density the infill density defines the amount of plastic used on the inside of the print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities.

Infill Settings Ultimaker Support . Cube The Cube's Designed Height Is 25Mm Tall But Actual Height Is 20Mm.

Choosing Infill Percentage For 3d Printed Parts 3dpros. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. Basically the final 3d printed model will have different infill densities depending on the region of the model. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. This allows it to print. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. Infill density the infill density defines the amount of plastic used on the inside of the print. For example, what does a 40% infill density look like compared to a 70% infill? There is too much superficial knowledge. The density of your infill makes a huge difference in the weight and durability of your print. In s3d it's a little bit different, we.

Expert Interview Anisoprint Ceo Fedor Antonov On Why Composite 3d Printing Is One Of The Biggest Trends In Am Amfg , This Means That The Object Becomes Sturdier And More Capable Of Handling Stress Without The Need For Increasing The 3D Printing Infill Density.

Change Infill Density In A Specific Section On A 3d Model For 3d Printing 8 Steps Instructables. All3dp is an editorially independent publication. For example, what does a 40% infill density look like compared to a 70% infill? There is too much superficial knowledge. This allows it to print. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. In s3d it's a little bit different, we. Editorial content, on principle, can not be bought or influenced. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. Infill density the infill density defines the amount of plastic used on the inside of the print. Basically the final 3d printed model will have different infill densities depending on the region of the model. The density of your infill makes a huge difference in the weight and durability of your print.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter . With A Low Infill Density (20%) The Cantilever Is Much More Likely To Break As The Short Extruded Clip Is Only Connected To The Body Of Print By A Small For Cheap Rapid Prints Rectangular Infill It The Best Selection Due To Its Quick Print Speed.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. Infill density the infill density defines the amount of plastic used on the inside of the print. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. The density of your infill makes a huge difference in the weight and durability of your print. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. For example, what does a 40% infill density look like compared to a 70% infill? All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. There is too much superficial knowledge. This allows it to print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. In s3d it's a little bit different, we. Basically the final 3d printed model will have different infill densities depending on the region of the model. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities.

Gradient Infill New Efficient Infill For 3d Prints Youtube : Basically The Final 3D Printed Model Will Have Different Infill Densities Depending On The Region Of The Model.

Cura 2 6 Different Infills In The Same Print Ideato3d. In s3d it's a little bit different, we. The density of your infill makes a huge difference in the weight and durability of your print. Infill density the infill density defines the amount of plastic used on the inside of the print. There is too much superficial knowledge. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! For example, what does a 40% infill density look like compared to a 70% infill? This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. All3dp is an editorially independent publication. This allows it to print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Basically the final 3d printed model will have different infill densities depending on the region of the model. Editorial content, on principle, can not be bought or influenced. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities.

Azniv Hovhannisyan : Printing At Higher Infill Densities Will Of Course Make Your Object Stronger, But At The Cost Of More Materials, Longer Printing Times, And Reduced Effectiveness Of The Additional Material Used.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. Editorial content, on principle, can not be bought or influenced. In s3d it's a little bit different, we. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Infill density the infill density defines the amount of plastic used on the inside of the print. The density of your infill makes a huge difference in the weight and durability of your print. Basically the final 3d printed model will have different infill densities depending on the region of the model. This allows it to print. There is too much superficial knowledge. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. For example, what does a 40% infill density look like compared to a 70% infill? All3dp is an editorially independent publication.

3d Printing Infill Styles The What When And Why Of Using Infill Padt Inc The Blog - It Works By Creating A Series Of 8 Subdivided Cubes Infill Density/Percentage Has A Pretty Significant Impact On Part Strength And Printing Time.

Paper Direct 3d Printing Of Highly Anisotropic Flexible Constriction Resistive Sensors For Multidirectional Proprioception In Soft Robots Robotics And Autonomous Systems Group. Infill density the infill density defines the amount of plastic used on the inside of the print. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. Basically the final 3d printed model will have different infill densities depending on the region of the model. This allows it to print. All3dp is an editorially independent publication. The density of your infill makes a huge difference in the weight and durability of your print. There is too much superficial knowledge. For example, what does a 40% infill density look like compared to a 70% infill? Editorial content, on principle, can not be bought or influenced. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. In s3d it's a little bit different, we. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts!

Choosing Infill Percentage For 3d Printed Parts 3dpros : Multiple Layer Heights In A.

Infill Settings Ultimaker Support. In s3d it's a little bit different, we. I must admit that it took me a while to catch on to all of the 3d printing jargon, yet i still have a difficult time grasping what a honeycomb pattern would look like in the various infill densities. Infill density the infill density defines the amount of plastic used on the inside of the print. This allows it to print. The workflow was based in the following processes in s3r we select the part and then choose the settings to change, in this case it was the fill density. There is too much superficial knowledge. The density of your infill makes a huge difference in the weight and durability of your print. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! For example, what does a 40% infill density look like compared to a 70% infill? Editorial content, on principle, can not be bought or influenced. Infill density is the amount of filament printed inside the object, and this directly relates to the strength, weight and printing duration of your print. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. This means that the object becomes sturdier and more capable of handling stress without the need for increasing the 3d printing infill density. Basically the final 3d printed model will have different infill densities depending on the region of the model.