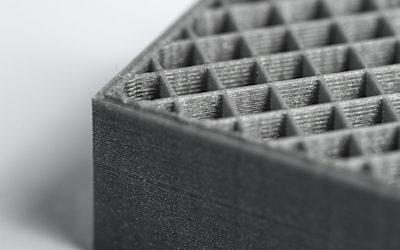

3D Printing Infill Explained. In 3d printing, the term infill refers to the structure that is printed inside an object. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. All3dp is an editorially independent publication. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. 3d printing software provides infill pattern selections for users to choose. It is extruded in a designated percentage and pattern, which is set in the slicing software. 3d print infill patterns explained. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Besides the actual printing process, infill will affect the strength or feel of the final product.

3D Printing Infill Explained - When It Comes To 3D Printing, Infill Is A Very Important Factor To A Print's Strength, Structure, And Weight.

Gaps Between Infill And Outline. 3d printing software provides infill pattern selections for users to choose. Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. It is extruded in a designated percentage and pattern, which is set in the slicing software. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. 3d print infill patterns explained. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Editorial content, on principle, can not be bought or influenced. In 3d printing, the term infill refers to the structure that is printed inside an object.

How to choose an infill for your 3d prints.

Learn how infill %, infill patterns and layer height impact the strength of a 3d print. These differences, the researchers explain, are found on a submillimeter scale in infill patterns. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. This display illustrates what happens when you print something without supports… what supports and a raft look like… and the final product after the raft. Basically the final 3d printed model will have different infill densities depending on the region of the model. How to choose an infill for your 3d prints. It can be difficult to explain important 3d printing concepts like infill percentage, shells, resolution, and the need for supports, smith explains. Thingiverse is a universe of things. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Triangular infill is the strongest infill pattern because triangles are the strongest shape. Confusions arise in determining the infill pattern with highest. 3d printing software provides infill pattern selections for users to choose. This shape is the most efficient infill and fastest to print, the goto infill for most things. There is a variety of different infills you'll see out there but i'm. 3d print infill patterns explained. The default infill amount for the printers at scitech business library is 5%. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. At a high infill %, hexagonal is essentially the same as linear and therefore the discussion is really between linear and diagonal. Say it 5 times fast! Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. I noticed that dropping the infill can dramatically reduce plastic consumption. But what are the differences, and. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. The term 3d printing can refer to a variety of processes in which. It is extruded in a designated percentage and pattern, which is set in the slicing software. Download files and build them with your 3d printer, laser cutter, or cnc. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. In 3d printing, the term infill refers to the structure that is printed inside an object. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts.

What Are The Advantages Of Gyroid Infill 3d Printing Stack Exchange : It Will Save You Material Much Of 3D Printing Is Really Structure And Design And I Feel That Having Some Knowledge In Why Nature Does What It Does Will Add Some Forethought To.

Testing 3d Printed Infill Patterns For Their Strength Youtube. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. It is extruded in a designated percentage and pattern, which is set in the slicing software. 3d printing software provides infill pattern selections for users to choose. Besides the actual printing process, infill will affect the strength or feel of the final product. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. 3d print infill patterns explained. Infill percentage in 3d printing. What is infill in 3d printing? Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. In 3d printing, the term infill refers to the structure that is printed inside an object. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced.

Over Extrusion Solid Infill 3d Printing 3d Printers Talk Manufacturing 3d Hubs : How Many Types Of Infill Pattern Have You Tried?

What Is Infill Xometry. It is extruded in a designated percentage and pattern, which is set in the slicing software. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. 3d print infill patterns explained. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. In 3d printing, the term infill refers to the structure that is printed inside an object. All3dp is an editorially independent publication. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter , It can be difficult to explain important 3d printing concepts like infill percentage, shells, resolution, and the need for supports, smith explains.

Gaps Between Infill And Outline. 3d printing software provides infill pattern selections for users to choose. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. What is infill in 3d printing? All3dp is an editorially independent publication. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. In 3d printing, the term infill refers to the structure that is printed inside an object. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. 3d print infill patterns explained. It is extruded in a designated percentage and pattern, which is set in the slicing software. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing.

Gradient Infill New Efficient Infill For 3d Prints Youtube . We'lL Then Cover Any Troubleshooting With Infill Related Problems And How To Compensate When Using Low Or No Infill.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs. What is infill in 3d printing? It is extruded in a designated percentage and pattern, which is set in the slicing software. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Besides the actual printing process, infill will affect the strength or feel of the final product. Editorial content, on principle, can not be bought or influenced. 3d printing software provides infill pattern selections for users to choose. In 3d printing, the term infill refers to the structure that is printed inside an object. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. All3dp is an editorially independent publication. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. 3d print infill patterns explained. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter - Furthermore, Hexagonal Infills Start To Look Very Similar To Linear Past 30% Infill.

Testing 3d Printed Infill Patterns For Their Strength Youtube. It is extruded in a designated percentage and pattern, which is set in the slicing software. 3d printing software provides infill pattern selections for users to choose. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. 3d print infill patterns explained. In 3d printing, the term infill refers to the structure that is printed inside an object. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. What is infill in 3d printing? There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. Besides the actual printing process, infill will affect the strength or feel of the final product. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

What Is The Best Infill Pattern For 3d Printing 3dprinterly , Learn How Infill %, Infill Patterns And Layer Height Impact The Strength Of A 3D Print.

What Is Infill In The 3d Printing Settings Flashforge. 3d print infill patterns explained. 3d printing software provides infill pattern selections for users to choose. Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. In 3d printing, the term infill refers to the structure that is printed inside an object. All3dp is an editorially independent publication. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. Besides the actual printing process, infill will affect the strength or feel of the final product. It is extruded in a designated percentage and pattern, which is set in the slicing software.

What Is 3d Printer Infill And When Should It Be Used Home 3d Print Guide . It Can Be Difficult To Explain Important 3D Printing Concepts Like Infill Percentage, Shells, Resolution, And The Need For Supports, Smith Explains.

Over Extrusion Solid Infill 3d Printing 3d Printers Talk Manufacturing 3d Hubs. What is infill in 3d printing? Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. It is extruded in a designated percentage and pattern, which is set in the slicing software. In 3d printing, the term infill refers to the structure that is printed inside an object. 3d printing software provides infill pattern selections for users to choose. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. 3d print infill patterns explained. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference.

Awesome Demonstration Of Different Infill Percentages 3dprinting . Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

3d Printing Stop Wasting Plastic On Infill Percentage Youtube. 3d print infill patterns explained. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. In 3d printing, the term infill refers to the structure that is printed inside an object. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. Besides the actual printing process, infill will affect the strength or feel of the final product. It is extruded in a designated percentage and pattern, which is set in the slicing software. 3d printing software provides infill pattern selections for users to choose. What is infill in 3d printing? Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. All3dp is an editorially independent publication.

How Much Does 3d Printing Cost Additive3d Asia . Infill Patterns Are Sometimes Overlooked In 3D Printing Because It's Just One Part Of Many Settings For Your Prints.

How To Use 3d Print Infill Settings Increase Strength Save Filament. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. 3d print infill patterns explained. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. In 3d printing, the term infill refers to the structure that is printed inside an object. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printing software provides infill pattern selections for users to choose. All3dp is an editorially independent publication. The infill the amount of material that occupies the internal part of the piece. Editorial content, on principle, can not be bought or influenced. What is infill in 3d printing? Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Besides the actual printing process, infill will affect the strength or feel of the final product. It is extruded in a designated percentage and pattern, which is set in the slicing software.

3d Print Infill Patterns Explained The 3d Bros : All3Dp Is An Editorially Independent Publication.

Infill Pattern Basics Simplify3d Youtube. The infill the amount of material that occupies the internal part of the piece. In 3d printing, the term infill refers to the structure that is printed inside an object. Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you want to use. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. It is extruded in a designated percentage and pattern, which is set in the slicing software. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. What is infill in 3d printing? There are several infill patterns it explains that different infill patterns had a maximum of 5% tensile strength differences meaning that the pattern alone didn't make too much difference. 3d printing software provides infill pattern selections for users to choose. Infill percentage in 3d printing. 3d print infill patterns explained.