3D Printing Infill Meaning. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The gyroid pattern has got to be one of the coolest you can use. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. Infill percentage in 3d printing. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. All3dp is an editorially independent publication. The process of 3d printing inherently tends to create. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. At a low infill percentage, the internal density of the cantilever is. Editorial content, on principle, can not be bought or influenced. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).

3D Printing Infill Meaning : 3D Printer Infill Patterns, Or The Internal Structure Of An Object, Are A Necessary Part Of Printing Some 3D Objects, Especially Those That This Means That Its Weakest Point Will Be The Small Area Attaching It To The Main Body Of The Object.

What Is Infill Xometry. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. Infill percentage in 3d printing. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. The gyroid pattern has got to be one of the coolest you can use. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. At a low infill percentage, the internal density of the cantilever is. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The process of 3d printing inherently tends to create.

The process of 3d printing inherently tends to create.

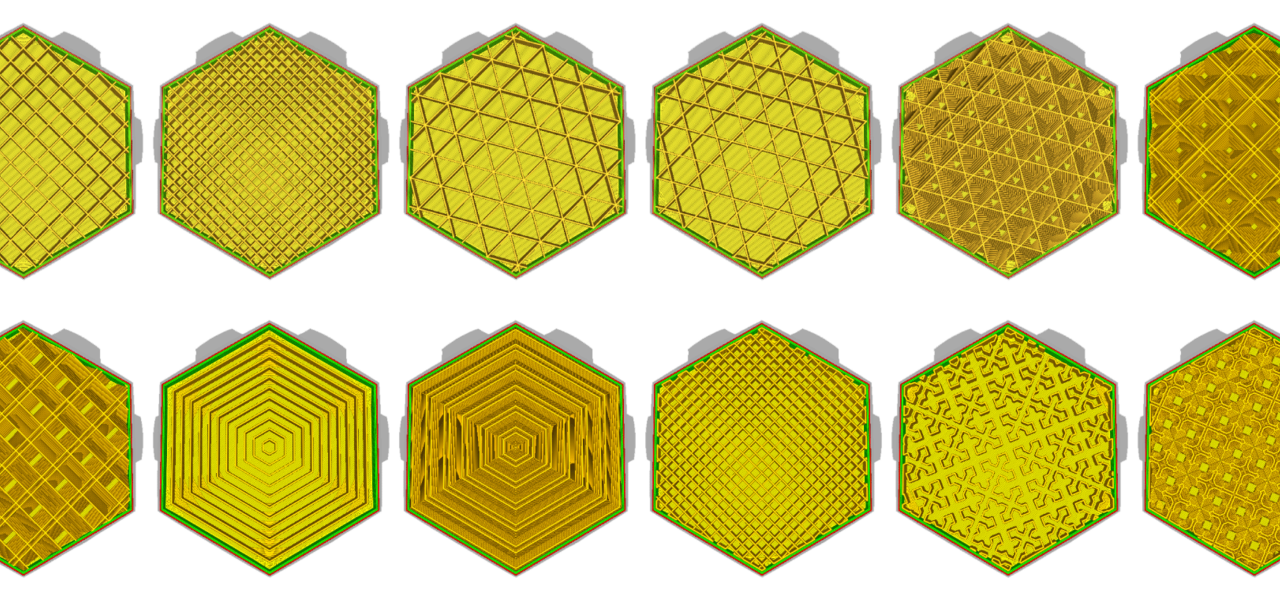

Thingiverse is a universe of things. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. This means it's putting out more plastic on each layer than the rectilinear infill pattern we looked at earlier, since that pattern only prints lines in one. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. It is extruded in a designated percentage and pattern, which is set in the slicing software. Hunter626103d printers 3d printing 3d printers. The process of 3d printing inherently tends to create. As you can tell from the photo above, the higher the infill the more densely filled the print is with material. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. First, infill prints very quickly and shells print very slowly. On top of these advantages gyroid infill prints relatively fast with respect to some other infill types and is close to isotropic (i.e. You can download free what is infill? Say it 5 times fast! This is because geometry matters to cells! Uniform in all orientations), meaning that is very suitable for flexible prints. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). They understand the substrates surrounding them and. In other words, reducing the infill from 100% reduces resistance less and less, which means that you might be able to find a more optimized solution with while the tests conducted only covered a small range of the possible materials and machines used today in desktop 3d printing, it does offer a great. Occur in sla printing and refer to cross in fdm printing the shell refers to the walls of the print that are exposed to the outside of the model. Relevant infill designs are recommended based on loading conditions and savings in production cost when compared to solid infill design. 3d prints are usually designed to be hollow for faster printing, less since supports are meant to be removed from the model after printing, you can get away with. Whether you're looking for a strong infill or an aesthetically pleasing one, simplify3d has several infill options to choose from. As of right now i can choose from a total of 7 different infill. Download files and build them with your 3d printer, laser cutter, or cnc. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. Basically the final 3d printed model will have different infill densities depending on the region of the model. Printing an object with 20% infill might mean a grid of squares with 5mm or 2mm spacing. The gyroid pattern has got to be one of the coolest you can use.

Slicer 3d Printing Wikipedia , There Are A Lot Of Concepts Within The Desktop 3D Printing Space Which Sometimes Are A Bit Complicated To Understand.

Best 3d Printing Infill Pattern 3dprintscape Com. The process of 3d printing inherently tends to create. Infill percentage in 3d printing. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. The gyroid pattern has got to be one of the coolest you can use. At a low infill percentage, the internal density of the cantilever is. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. The infill the amount of material that occupies the internal part of the piece. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Editorial content, on principle, can not be bought or influenced.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter : 3D Prints Are Usually Designed To Be Hollow For Faster Printing, Less Since Supports Are Meant To Be Removed From The Model After Printing, You Can Get Away With.

3d Printing Infill The Basics Simply Explained All3dp. At a low infill percentage, the internal density of the cantilever is. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. The gyroid pattern has got to be one of the coolest you can use. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The infill the amount of material that occupies the internal part of the piece.

What Are The Advantages Of Gyroid Infill 3d Printing Stack Exchange : 3d printing 101 it & software video | edurev video for it & software is made by best teachers who have written some of the best books of it & software.

What Is Infill In The 3d Printing Settings Flashforge. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. The infill the amount of material that occupies the internal part of the piece. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. At a low infill percentage, the internal density of the cantilever is. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. The gyroid pattern has got to be one of the coolest you can use. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. The process of 3d printing inherently tends to create. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).

Mechanical Testing 3d Printed Parts Results And Recommendations Engineerdog . The Infill The Amount Of Material That Occupies The Internal Part Of The Piece.

Slic3r Manual Print Settings. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The infill the amount of material that occupies the internal part of the piece. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. The gyroid pattern has got to be one of the coolest you can use. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. The process of 3d printing inherently tends to create. Editorial content, on principle, can not be bought or influenced. At a low infill percentage, the internal density of the cantilever is. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. Infill percentage in 3d printing.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs , The Term 3D Printing Can Refer To A Variety Of Processes In Which.

Infill Settings Ultimaker Support. Editorial content, on principle, can not be bought or influenced. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. The infill the amount of material that occupies the internal part of the piece. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The process of 3d printing inherently tends to create. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. At a low infill percentage, the internal density of the cantilever is. The gyroid pattern has got to be one of the coolest you can use.

What Are The Advantages Of Gyroid Infill 3d Printing Stack Exchange . Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

3d Printing In Pharmaceutical And Medical Applications Recent Achievements And Challenges Drugpatentwatch Make Better Decisions. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The process of 3d printing inherently tends to create. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The gyroid pattern has got to be one of the coolest you can use. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. All3dp is an editorially independent publication. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). At a low infill percentage, the internal density of the cantilever is. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered.

Fabrication Of Scalable And Structured Tissue Engineering Scaffolds Using Water Dissolvable Sacrificial 3d Printed Moulds Sciencedirect : Stefan Of Cnc Kitchen Does A Lot Of 3D Printer Technique Testing.

Gradient Infill For 3d Prints Cnc Kitchen. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. The process of 3d printing inherently tends to create. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. The gyroid pattern has got to be one of the coolest you can use. At a low infill percentage, the internal density of the cantilever is. Infill percentage in 3d printing. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. The infill the amount of material that occupies the internal part of the piece.

What Is Infill In The 3d Printing Settings Flashforge : Telling The Slicer To Infill A Part With A Grid Of Squares Spaced 10Mm While Each Individual Layer Of Infill Looks Like A Series Of Triangles And Irregular Hexagons, When Assembled Into A Printed 3D Object, This Infill.

Fdm Fused Deposition Modeling Or Fff Pjp Lpd. At a low infill percentage, the internal density of the cantilever is. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. Infill percentage in 3d printing. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. The process of 3d printing inherently tends to create. Editorial content, on principle, can not be bought or influenced. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. The gyroid pattern has got to be one of the coolest you can use. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill.

Gradient Infill For 3d Prints Cnc Kitchen : First, Infill Prints Very Quickly And Shells Print Very Slowly.

Troubleshooting Guide To Common 3d Printing Problems All3dp. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Infill percentage in 3d printing. The gyroid pattern has got to be one of the coolest you can use. At a low infill percentage, the internal density of the cantilever is. The process of 3d printing inherently tends to create. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. All3dp is an editorially independent publication. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. The infill the amount of material that occupies the internal part of the piece. Editorial content, on principle, can not be bought or influenced. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).

Infill Not Reaching Perimeter 3d Printing Stack Exchange : On Top Of These Advantages Gyroid Infill Prints Relatively Fast With Respect To Some Other Infill Types And Is Close To Isotropic (I.e.

3d Printing Infill The Basics Simply Explained All3dp. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. Increasing infill density means infill shouldn't show through the walls has many retractions, not great for flexibles or less viscous materials (runny) not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill. All3dp is an editorially independent publication. The gyroid pattern has got to be one of the coolest you can use. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. The process of 3d printing inherently tends to create. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that this means that its weakest point will be the small area attaching it to the main body of the object. At a low infill percentage, the internal density of the cantilever is. Editorial content, on principle, can not be bought or influenced. This has several interesting consequences on anisotropic means that the properties of the material depends on the direction considered. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.