3D Printing Infill Metal. Best infill for strength vs material used. A patent landscape analysis 2019. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This shape is the most efficient infill and fastest to print, the goto infill for most things. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Consider a print with low infill that is going to be drilled and then screwed to another surface. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Cnc machining materials 3d printing materials sheet metal materials injection molding materials.

3D Printing Infill Metal : What Would Be The Best Infill Pattern For Structural Parts?

3d Printing Infill The Basics Simply Explained All3dp. Consider a print with low infill that is going to be drilled and then screwed to another surface. Editorial content, on principle, can not be bought or influenced. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. A patent landscape analysis 2019. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This shape is the most efficient infill and fastest to print, the goto infill for most things. Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication.

Besides the actual printing process, infill will affect the strength or feel of the final product.

Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. In theory, spd can work with any metal combinations where the infill metal has lower melting. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Triangular infill is the strongest infill pattern because triangles are the strongest shape. Infill generated from type a machine's cura beta. Editorial content, on principle, can not be bought or influenced. Download files and build them with your 3d printer, laser cutter, or cnc. Consider a print with low infill that is going to be drilled and then screwed to another surface. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. Is there a way to compensate for warping in your 3d printing by. Say it 5 times fast! Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Right now, infill is generated in a slicer by specifying a percentage. The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. All3dp is an editorially independent publication. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. While each individual layer of infill looks like a series of triangles and irregular hexagons, when assembled into a printed 3d object, this infill forms. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. As of right now i can choose from a total of 7 different infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. The printer itself is material agnostic, and can pour any powder that flows though a small hole. 3d printer that prints solid, 100% dense, precise, and strong metal objects. This shape is the most efficient infill and fastest to print, the goto infill for most things. It only takes a minute to sign up. What would be the best infill pattern for structural parts? 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Thingiverse is a universe of things. Desktop metal to go public as a $2.5 billion 3d printing business, raising estimated $575 million in funding. Infill percentage in 3d printing.

3d Printing Assisted Finite Element Analysis For Optimising The Manufacturing Parameters Of A Lumbar Fusion Cage Sciencedirect . Cnc Machining Materials 3D Printing Materials Sheet Metal Materials Injection Molding Materials.

Dhruv Bhate On Twitter Tetrahedral Lattice Infill For Weight Reduction With Metal 3dprinting Additivemanufacturing 3dmetalprintmag Event Courtesy Renishawplc Https T Co Xfrpd7i2x1. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. This shape is the most efficient infill and fastest to print, the goto infill for most things. A patent landscape analysis 2019. All3dp is an editorially independent publication. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Consider a print with low infill that is going to be drilled and then screwed to another surface. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product.

Help Infill Lines Show On The Outside Cura Settings In Comments 3dprinting . The Infill The Amount Of Material That Occupies The Internal Part Of The Piece.

Why Should You Start 3d Printing With Stainless Steel. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Consider a print with low infill that is going to be drilled and then screwed to another surface. Editorial content, on principle, can not be bought or influenced. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used.

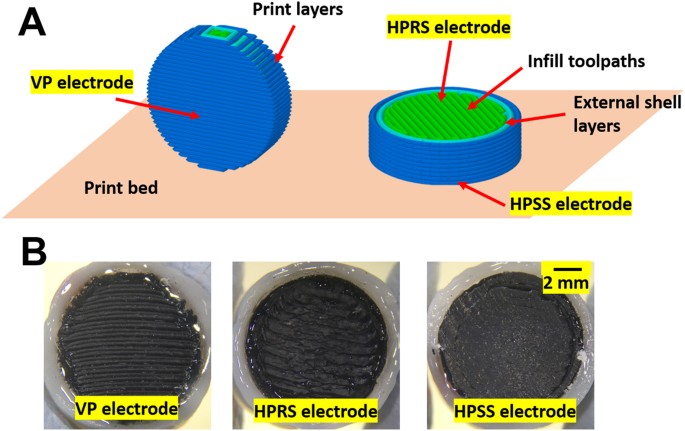

3d Printed Test Pieces With Different Infill Percentages For Electrical Download Scientific Diagram : Consider a print with low infill that is going to be drilled and then screwed to another surface.

How To Make Stronger 3d Prints Shells Vs Infill Additive Manufacturing Podcast Youtube. Best infill for strength vs material used. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. All3dp is an editorially independent publication. This shape is the most efficient infill and fastest to print, the goto infill for most things. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. A patent landscape analysis 2019. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Besides the actual printing process, infill will affect the strength or feel of the final product. Consider a print with low infill that is going to be drilled and then screwed to another surface.

3d Printing Infill And Density Visual 3d Printing Diy 3d Printer Designs 3d Printer Kit , Where A 3D Printed Part Is Going To Be Drilled Or Screwed Infill Percentage Becomes A Very Important Factor.

Infill Is Rough How To Enhance 3d Printing Stack Exchange. Besides the actual printing process, infill will affect the strength or feel of the final product. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Editorial content, on principle, can not be bought or influenced. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. A patent landscape analysis 2019. This shape is the most efficient infill and fastest to print, the goto infill for most things. Consider a print with low infill that is going to be drilled and then screwed to another surface. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Best infill for strength vs material used.

Sem Images Of 3d Printed Cha Scaffolds At Different Infill Densities Download Scientific Diagram - Desktop Metal To Go Public As A $2.5 Billion 3D Printing Business, Raising Estimated $575 Million In Funding.

Infill With Modulated Stiffness For 3d Printing More Elastic Infill Is Download Scientific Diagram. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. A patent landscape analysis 2019. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Besides the actual printing process, infill will affect the strength or feel of the final product. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Consider a print with low infill that is going to be drilled and then screwed to another surface.

Cura 2 6 Different Infills In The Same Print Ideato3d : The Workflow Was Based In The Following Processes In This Instructables I Aim To Demonstrate, In A Simple Way, How To Reinforce A Specific Region In A 3D Printer Part, By Changing The Part's Infill.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. All3dp is an editorially independent publication. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. A patent landscape analysis 2019. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Best infill for strength vs material used. Consider a print with low infill that is going to be drilled and then screwed to another surface.

How To Strengthen 3d Printed Parts In 5 Simple Ways Manufactur3d : Infill Generated From Type A Machine's Cura Beta.

3d Printing Process. This shape is the most efficient infill and fastest to print, the goto infill for most things. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. Consider a print with low infill that is going to be drilled and then screwed to another surface. All3dp is an editorially independent publication. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Editorial content, on principle, can not be bought or influenced. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Besides the actual printing process, infill will affect the strength or feel of the final product. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Best infill for strength vs material used. A patent landscape analysis 2019.

Infill With Modulated Stiffness For 3d Printing More Elastic Infill Is Download Scientific Diagram , A Patent Landscape Analysis 2019.

Forming Sheet Metal Parts With 3d Printed Dies Hackaday. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Consider a print with low infill that is going to be drilled and then screwed to another surface. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Best infill for strength vs material used. Editorial content, on principle, can not be bought or influenced. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. All3dp is an editorially independent publication. Besides the actual printing process, infill will affect the strength or feel of the final product. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. A patent landscape analysis 2019.

10 Best Metal 3d Printers 3d Printer Review Site Updated 2019 - Discover The Top 3D Printing Materials Used In The Industry Today.

3d Print Infill Percentage Disks Makerware Profiles By Creativetools Thingiverse. Consider a print with low infill that is going to be drilled and then screwed to another surface. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. A patent landscape analysis 2019. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor.

Gradient Infill Puts More Plastic Where You Want It Hackaday - Thingiverse Is A Universe Of Things.

These 3d Printable Tools Help You Understand Infill Percentages Number Of Shells And More 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. This shape is the most efficient infill and fastest to print, the goto infill for most things. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. A patent landscape analysis 2019. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Consider a print with low infill that is going to be drilled and then screwed to another surface. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Besides the actual printing process, infill will affect the strength or feel of the final product. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material.