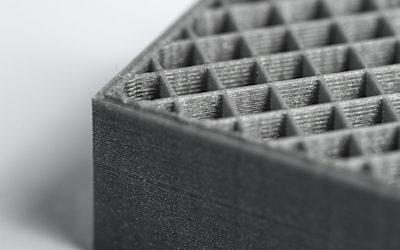

3D Printing Infill Speed. The print speed calculator has been developed for helping users defining their optimal speed and flow. This is my first print on my first 3d printer. The infill pattern i probably use the most is triangular. This will greatly help improve part accuracy and consistency across materials and configurations. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. How to choose infill percentage. These patterns are some of the best for high strength prints while still printing at good speeds. I need to get the printer off the. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. If you do not use this structure, the 3d print will take a longer time before it is finished. Infill is the internal structure generated to save material when printing the interior of 3d prints. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Print speed is the main speed setting that will influence your 3d prints. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically.

3D Printing Infill Speed , Triangular Infill Is The Strongest Infill Pattern Because Triangles Are The Strongest Shape.

Infill Settings In Simplify3d Updated Cincinnati Incorporated. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. The infill pattern i probably use the most is triangular. Infill is the internal structure generated to save material when printing the interior of 3d prints. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. How to choose infill percentage. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. I need to get the printer off the. This is my first print on my first 3d printer. This will greatly help improve part accuracy and consistency across materials and configurations. If you do not use this structure, the 3d print will take a longer time before it is finished. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. The print speed calculator has been developed for helping users defining their optimal speed and flow. Print speed is the main speed setting that will influence your 3d prints. These patterns are some of the best for high strength prints while still printing at good speeds.

The reason for this is a combination of time required to come up to full speed due to acceleration and.

We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. This shape is the most efficient infill and fastest to print, the goto infill for most things. 3d printing speed measures the amount of manufactured material over a given time period (. Our perimeter speeds are a fraction of that (per our settings), but even infill is printing somewhere nearer 150mm/s. 60 mm/s look at the infi. The reason for this is a combination of time required to come up to full speed due to acceleration and. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own. If you do not use this structure, the 3d print will take a longer time before it is finished. Slice a model with the following speed parameters: ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. The layer height of your 3d print is very dependent on the nozzle size of your 3d printer as well as the infill overlap refers to the percentage the infill will overlap onto the shells. 100 mm/s outer wall speed: The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. Some are better for speed, some are better for strength. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. As to decreasing ringing, you can try to decrease print speed of the outermost wall to around 1/2 or less of your standard printspeed of the other walls. They are least likely to deform and provide the best support structure behind the the strength and the speed combined makes triangular infill one of the best choices for infill in 3d printing. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. These patterns are some of the best for high strength prints while still printing at good speeds. Learn how to tune your printer's axis up to maximum speed! This is my first print on my first 3d printer. Infill is the internal structure generated to save material when printing the interior of 3d prints. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. It makes the print more stable at higher speeds and reduces lines generated by imperfections. You want to print with your lithophane placed along the y axis as seen in the picture below. When it comes combining and optimizing mechanical strength, speed, and costs not all 3d printing is created equal. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. 30 mm/s inner wall speed: This will greatly help improve part accuracy and consistency across materials and configurations.

5 Settings Relevant To Printing Speed In A 3d Slicing Software Flashforge . Slice A Model With The Following Speed Parameters:

Guide To Slic3r 9 Steps Instructables. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. These patterns are some of the best for high strength prints while still printing at good speeds. The print speed calculator has been developed for helping users defining their optimal speed and flow. This will greatly help improve part accuracy and consistency across materials and configurations. How to choose infill percentage. I need to get the printer off the. Print speed is the main speed setting that will influence your 3d prints. The infill pattern i probably use the most is triangular. Infill is the internal structure generated to save material when printing the interior of 3d prints. This is my first print on my first 3d printer. If you do not use this structure, the 3d print will take a longer time before it is finished. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage.

A Parametric Study Of 3d Printed Polymer Gears Springerlink , Say It 5 Times Fast!

5 Settings Relevant To Printing Speed In A 3d Slicing Software Flashforge. The infill pattern i probably use the most is triangular. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This is my first print on my first 3d printer. The print speed calculator has been developed for helping users defining their optimal speed and flow. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. If you do not use this structure, the 3d print will take a longer time before it is finished. I need to get the printer off the. How to choose infill percentage. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically.

Much Stronger 3d Prints Due To Less Cooling Testing Pla Petg Youtube - The infill the amount of material that occupies the internal part of the piece.

5 Settings Relevant To Printing Speed In A 3d Slicing Software Flashforge. How to choose infill percentage. This will greatly help improve part accuracy and consistency across materials and configurations. Print speed is the main speed setting that will influence your 3d prints. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. I need to get the printer off the. The print speed calculator has been developed for helping users defining their optimal speed and flow. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This is my first print on my first 3d printer. The infill pattern i probably use the most is triangular. These patterns are some of the best for high strength prints while still printing at good speeds. Infill is the internal structure generated to save material when printing the interior of 3d prints. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. If you do not use this structure, the 3d print will take a longer time before it is finished. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model.

5 Settings Relevant To Printing Speed In A 3d Slicing Software Flashforge : What Would Be The Best Infill Pattern For Structural Parts?

3d Printing Parameters 3d Printing Blog. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. How to choose infill percentage. Infill is the internal structure generated to save material when printing the interior of 3d prints. The print speed calculator has been developed for helping users defining their optimal speed and flow. This will greatly help improve part accuracy and consistency across materials and configurations. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. This is my first print on my first 3d printer. The infill pattern i probably use the most is triangular. Print speed is the main speed setting that will influence your 3d prints. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. These patterns are some of the best for high strength prints while still printing at good speeds. I need to get the printer off the. If you do not use this structure, the 3d print will take a longer time before it is finished. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs : 100 Mm/S Outer Wall Speed:

Is This A Bad Quality Print For 50mm S Speed Top Bottom Wall And Infill Speed In Cura 3dprinting. Infill is the internal structure generated to save material when printing the interior of 3d prints. This is my first print on my first 3d printer. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. How to choose infill percentage. I need to get the printer off the. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This will greatly help improve part accuracy and consistency across materials and configurations. The print speed calculator has been developed for helping users defining their optimal speed and flow. The infill pattern i probably use the most is triangular. Print speed is the main speed setting that will influence your 3d prints. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. These patterns are some of the best for high strength prints while still printing at good speeds. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. If you do not use this structure, the 3d print will take a longer time before it is finished.

Slic3r Manual Print Settings , This Will Greatly Help Improve Part Accuracy And Consistency Across Materials And Configurations.

Recommended Infill Speed Temp Ultimaker Cura Ultimaker Community Of 3d Printing Experts. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. This is my first print on my first 3d printer. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. If you do not use this structure, the 3d print will take a longer time before it is finished. Print speed is the main speed setting that will influence your 3d prints. These patterns are some of the best for high strength prints while still printing at good speeds. I need to get the printer off the. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. The print speed calculator has been developed for helping users defining their optimal speed and flow. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. The infill pattern i probably use the most is triangular. This will greatly help improve part accuracy and consistency across materials and configurations. Infill is the internal structure generated to save material when printing the interior of 3d prints. How to choose infill percentage.

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality , Infill Is The Internal Structure Generated To Save Material When Printing The Interior Of 3D Prints.

Edit Gcode To Change Infill Speed How Do I Print This Printing Help Prusa3d Forum. Print speed is the main speed setting that will influence your 3d prints. These patterns are some of the best for high strength prints while still printing at good speeds. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. The infill pattern i probably use the most is triangular. The print speed calculator has been developed for helping users defining their optimal speed and flow. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. How to choose infill percentage. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. If you do not use this structure, the 3d print will take a longer time before it is finished. I need to get the printer off the. This is my first print on my first 3d printer. Infill is the internal structure generated to save material when printing the interior of 3d prints. This will greatly help improve part accuracy and consistency across materials and configurations. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage.

Speed Up Your 3d Prints Without Sacrificing Quality By Changing Your Infill Layer Height Techwit , What Would Be The Best Infill Pattern For Structural Parts?

Low Poly Ring By Levenement71 3d Printed Ring 3d Printing Projects 3d Printing Diy. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. Infill is the internal structure generated to save material when printing the interior of 3d prints. The infill pattern i probably use the most is triangular. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. Print speed is the main speed setting that will influence your 3d prints. I need to get the printer off the. This is my first print on my first 3d printer. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. These patterns are some of the best for high strength prints while still printing at good speeds. The print speed calculator has been developed for helping users defining their optimal speed and flow. How to choose infill percentage. If you do not use this structure, the 3d print will take a longer time before it is finished. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This will greatly help improve part accuracy and consistency across materials and configurations.

5 Settings Relevant To Printing Speed In A 3d Slicing Software Flashforge - Now, The Early Firmwares Simply Assumed That The Printer Can Instantly Speed Up To The Speed You Wanted And Also Instantly Slow Down To Zero.

The Best Cura Infill Pattern For Your Needs All3dp. Infill is the internal structure generated to save material when printing the interior of 3d prints. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. These patterns are some of the best for high strength prints while still printing at good speeds. This will greatly help improve part accuracy and consistency across materials and configurations. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. I need to get the printer off the. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. The infill pattern i probably use the most is triangular. The print speed calculator has been developed for helping users defining their optimal speed and flow. Print speed is the main speed setting that will influence your 3d prints. If you do not use this structure, the 3d print will take a longer time before it is finished. This is my first print on my first 3d printer. How to choose infill percentage.

Much Stronger 3d Prints Due To Less Cooling Testing Pla Petg Youtube , Some Are Better For Speed, Some Are Better For Strength.

The Best Cura Infill Pattern For Your Needs All3dp. Infill is the internal structure generated to save material when printing the interior of 3d prints. This is my first print on my first 3d printer. Print speed is the main speed setting that will influence your 3d prints. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. These patterns are some of the best for high strength prints while still printing at good speeds. I need to get the printer off the. Solid prints consist of thicker and stronger outliners and are filled in with honeycomb structure. The infill pattern i probably use the most is triangular. If you're printing a part with thin infill or walls, some lines may start dropping out of the sliced model. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of cubic is a great compromise between strength, print speed and keeping the model light / low filament usage. How to choose infill percentage. This will greatly help improve part accuracy and consistency across materials and configurations. The infill pattern will marginally affect print speeds, while infill density will alter print times drastically. The print speed calculator has been developed for helping users defining their optimal speed and flow. If you do not use this structure, the 3d print will take a longer time before it is finished.