3D Printing Materials Strength. Discover the top 3d printing materials used in the industry today. Tensile strength is the measurement of a material's resilience. Editorial content, on principle, can not be bought or influenced. Select the best material for your select one of the materials below to get started. Each image highlights a sample project that was polycarbonate is known for its strength and durability. It's the maximum amount of stress the material can take before breaking. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. It has very high heat and impact resistance. All3dp is an editorially independent publication. Different 3d printing materials support different combinations of toughness and tensile strength. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Tensile strength is typically divided into three categories 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. So let's get on with it and start talking about our materials. Tensile strength measures the ability of a material to be pulled from both ends and not break.

3D Printing Materials Strength , Tpe Filament Can Be Used To Make Parts That Can Bend Or.

Durable High Strength 3d Filament Pla Supplies 1 75mm 3d Printer Filament Printing Material For 3d Printing Pen 3d Printer 3d Printing Materials Aliexpress. It has very high heat and impact resistance. Discover the top 3d printing materials used in the industry today. Tensile strength measures the ability of a material to be pulled from both ends and not break. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Select the best material for your select one of the materials below to get started. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Tensile strength is the measurement of a material's resilience. So let's get on with it and start talking about our materials. Tensile strength is typically divided into three categories Different 3d printing materials support different combinations of toughness and tensile strength. It's the maximum amount of stress the material can take before breaking. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Each image highlights a sample project that was polycarbonate is known for its strength and durability.

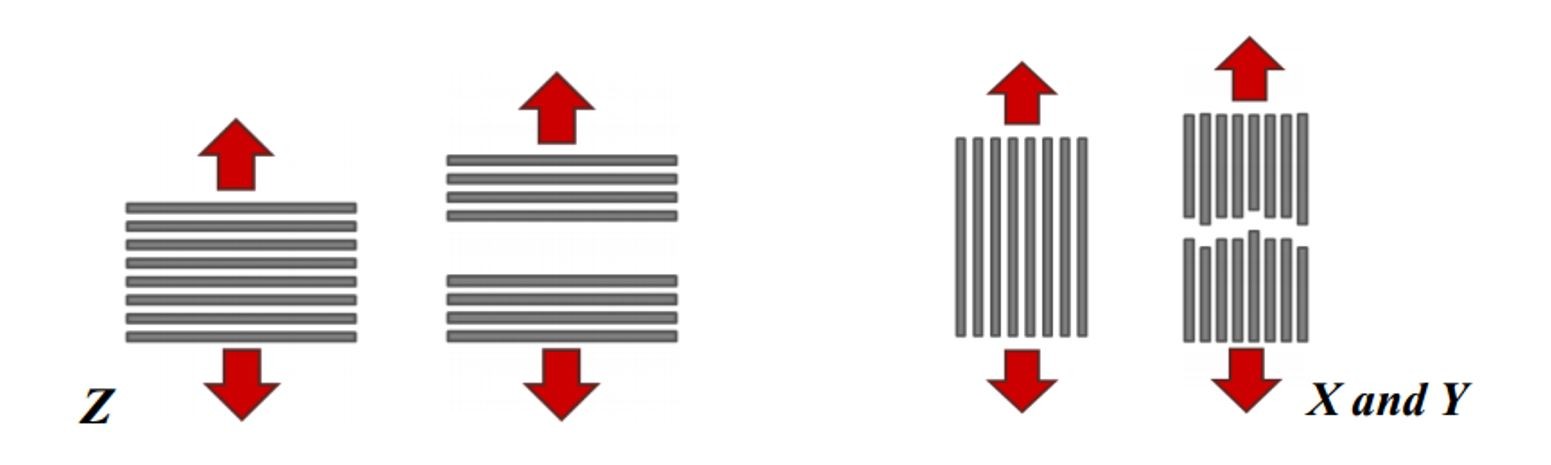

Thinner layers have more extrusions of material per part, but the strands have a smaller cross section.

Layer height in 3d printing doesn't substantially affect part strength. ··· high strength,high toughness,high transparency 3d diy printer filament polycarbonate pc material 3d printing filament description colors diameter there are 142 suppliers who sells 3d printer material strength on alibaba.com, mainly located in asia. So let's get on with it and start talking about our materials. Fdm printing necessarily involves heating the print material so that it can be extruded. The material is ideal for device parts that need to be flexible, such as touchscreens. Moreover, there are important factors such as material type, texture, cost, etc with proper knowledge equipped and the right materials being used, industrial 3d printing can be done efficiently. After crafting ways to leverage everything from human tissue to chocolate to lunar dust, you must wonder, what material can at jabil, we've noticed more companies requesting custom materials with specific strength, chemical resistance or machine integration properties. It has very high heat and impact resistance. Discover the top 3d printing materials used in the industry today. All 3d printed parts are not made equal, and if the clothes make the man when 3d printing an object, choosing the correct material for the application is just as critical as most of the hardest 3d printing materials are metals. Graphene has become a popular choice for 3d printing because of its strength and conductivity. Polyvinyl alcohol (pva) is one of a new class of 3d printing pros: What materials can be used in fdm 3d printing? Different 3d printing materials support different combinations of toughness and tensile strength. Durable resin has the highest impact strength and elongation at break compared to the other sla materials. The materials used in 3d printing have been improving, as would be expected. The two primary technologies used for desktop 3d printing are fused deposition modeling (fdm) and stereolithography (sla). 3d printing filament is created using a process of heating, extruding and cooling plastic to transform nurdles into the finished product. For 2d printing, we're most familiar with inkjet printers that use liquid inks. Brittle prints with relatively low mechanical strength compared to other materials, melts easily under high heat (though sometimes useful for. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Tensile strength measures the ability of a material to be pulled from both ends and not break. Too low or too high temperature, poor cooling or storage makes even filaments like pet, abs and ultem perform weak. Pigments or other additives are added to the material before it is melted to create coloured filament or filament with special properties, e.g. 3d printing functional parts with known mechanical properties is challenging using variable open source 3d printers. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. They also offer good strength and thermal. The materials used for 3d printing are as diverse as the products that result from the process. Editorial content, on principle, can not be bought or influenced. Part of the fused deposition modelling (a type of 3d printing technology) process is extrusion. These materials have their own unique features, strengths and weaknesses.

3d Printing Has An Urgent Need For Cybersecurity Designnews Com : Before Printing Your Part, Consider Where The Pressures And Loads Are In Your Part And How It Will Propagate Through The Model.

Interlayer Adhesion Improvements For 3d Construction Printing 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Different 3d printing materials support different combinations of toughness and tensile strength. Editorial content, on principle, can not be bought or influenced. It's the maximum amount of stress the material can take before breaking. Tensile strength measures the ability of a material to be pulled from both ends and not break. Tensile strength is the measurement of a material's resilience. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Discover the top 3d printing materials used in the industry today. Select the best material for your select one of the materials below to get started. It has very high heat and impact resistance. All3dp is an editorially independent publication. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. So let's get on with it and start talking about our materials. Tensile strength is typically divided into three categories Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Each image highlights a sample project that was polycarbonate is known for its strength and durability.

3d Printing Materials . Nylon Is A Low Friction Material That Boasts Very High Strength And Durability.

Mechanical Properties Testing Part 1 Tensile Strength Iso 527. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Tensile strength measures the ability of a material to be pulled from both ends and not break. It's the maximum amount of stress the material can take before breaking. Tensile strength is the measurement of a material's resilience. Select the best material for your select one of the materials below to get started. So let's get on with it and start talking about our materials. Discover the top 3d printing materials used in the industry today. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Editorial content, on principle, can not be bought or influenced. Tensile strength is typically divided into three categories

The Properties Of 3d Printed Plastic Parts 3faktur - All printers need some kind of substance to print with.

A Novel Generalized Stress Invariant Based Strength Model For Inter Layer Failure Of Fff 3d Printing Pla Material Sciencedirect. Editorial content, on principle, can not be bought or influenced. Select the best material for your select one of the materials below to get started. Each image highlights a sample project that was polycarbonate is known for its strength and durability. All3dp is an editorially independent publication. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. It has very high heat and impact resistance. It's the maximum amount of stress the material can take before breaking. So let's get on with it and start talking about our materials. Tensile strength is the measurement of a material's resilience. Discover the top 3d printing materials used in the industry today. Tensile strength is typically divided into three categories Different 3d printing materials support different combinations of toughness and tensile strength. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Tensile strength measures the ability of a material to be pulled from both ends and not break.

Can 3d Printing Lead To Lighter Stronger Materials Engineering Com . Graphene Has Become A Popular Choice For 3D Printing Because Of Its Strength And Conductivity.

Amazon Com Blue Pla Filament 1 75 Mm 3d Printing Filament 1kg 2 2lbs Spool 3d Printer Material Cc3d Pla Max Ocean Blue Color Strength Than Normal Pla Pro Plus Filament Office Products. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. It's the maximum amount of stress the material can take before breaking. So let's get on with it and start talking about our materials. Discover the top 3d printing materials used in the industry today. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Editorial content, on principle, can not be bought or influenced. It has very high heat and impact resistance. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Tensile strength is typically divided into three categories Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Different 3d printing materials support different combinations of toughness and tensile strength. All3dp is an editorially independent publication. Select the best material for your select one of the materials below to get started. Tensile strength is the measurement of a material's resilience. Tensile strength measures the ability of a material to be pulled from both ends and not break.

3d Printing Market By Source Type Application Geography Covid 19 Impact Analysis Marketsandmarkets , Has Some Of The Lightweight Strength Of Carbon Fiber.

What Is The Strongest 3d Printer Filament Airwolf 3d. Editorial content, on principle, can not be bought or influenced. Discover the top 3d printing materials used in the industry today. Tensile strength is the measurement of a material's resilience. Different 3d printing materials support different combinations of toughness and tensile strength. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. It's the maximum amount of stress the material can take before breaking. So let's get on with it and start talking about our materials. All3dp is an editorially independent publication. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Tensile strength measures the ability of a material to be pulled from both ends and not break. It has very high heat and impact resistance. Select the best material for your select one of the materials below to get started. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Tensile strength is typically divided into three categories Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization.

Pc Filament 3d Printing Material Strength Resist Ultraviolet Rays . The Top Countries Of Supplier Is China, From.

Navigating Through The Selection Of 3d Printing Materials Know Your Strengths 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Tensile strength is typically divided into three categories Discover the top 3d printing materials used in the industry today. So let's get on with it and start talking about our materials. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Tensile strength measures the ability of a material to be pulled from both ends and not break. Different 3d printing materials support different combinations of toughness and tensile strength. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Tensile strength is the measurement of a material's resilience. Editorial content, on principle, can not be bought or influenced. Select the best material for your select one of the materials below to get started. It's the maximum amount of stress the material can take before breaking. It has very high heat and impact resistance. All3dp is an editorially independent publication.

Navigating Through The Selection Of 3d Printing Materials Know Your Strengths 3dprint Com The Voice Of 3d Printing Additive Manufacturing , Too Low Or Too High Temperature, Poor Cooling Or Storage Makes Even Filaments Like Pet, Abs And Ultem Perform Weak.

What Is The Strongest 3d Printer Filament Airwolf 3d. Editorial content, on principle, can not be bought or influenced. It has very high heat and impact resistance. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Different 3d printing materials support different combinations of toughness and tensile strength. Each image highlights a sample project that was polycarbonate is known for its strength and durability. So let's get on with it and start talking about our materials. It's the maximum amount of stress the material can take before breaking. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Tensile strength is typically divided into three categories Discover the top 3d printing materials used in the industry today. Select the best material for your select one of the materials below to get started. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Tensile strength measures the ability of a material to be pulled from both ends and not break. Tensile strength is the measurement of a material's resilience. All3dp is an editorially independent publication.

Mechanical Testing 3d Printed Parts Results And Recommendations Engineerdog - 3D Printer Pla Filament 1.75Mm, Labists Plastic 3D Printing Pla Filament Bundle 1Kg/2.2Lb,.25Kg/Spool 4 Colors (White, Red, Black, Blue).

All You Need To Know About Peek For 3d Printing 3dnatives. All3dp is an editorially independent publication. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Each image highlights a sample project that was polycarbonate is known for its strength and durability. Tensile strength measures the ability of a material to be pulled from both ends and not break. Select the best material for your select one of the materials below to get started. It has very high heat and impact resistance. Discover the top 3d printing materials used in the industry today. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Tensile strength is the measurement of a material's resilience. Tensile strength is typically divided into three categories So let's get on with it and start talking about our materials. It's the maximum amount of stress the material can take before breaking. Editorial content, on principle, can not be bought or influenced. Different 3d printing materials support different combinations of toughness and tensile strength.

What Materials Are Used For 3d Printing Sharretts Plating Company : It Has Very High Heat And Impact Resistance.

Designpoint Blog Markforged And Solidworks Join Forces. Tensile strength is typically divided into three categories Different 3d printing materials support different combinations of toughness and tensile strength. Tensile strength measures the ability of a material to be pulled from both ends and not break. It's the maximum amount of stress the material can take before breaking. It has very high heat and impact resistance. Select the best material for your select one of the materials below to get started. So let's get on with it and start talking about our materials. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Tensile strength is the measurement of a material's resilience. Editorial content, on principle, can not be bought or influenced. Discover the top 3d printing materials used in the industry today. All3dp is an editorially independent publication. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. Each image highlights a sample project that was polycarbonate is known for its strength and durability.

Choosing Your 3d Printing Material It S About More Than Strength , ··· High Strength,High Toughness,High Transparency 3D Diy Printer Filament Polycarbonate Pc Material 3D Printing Filament Description Colors Diameter There Are 142 Suppliers Who Sells 3D Printer Material Strength On Alibaba.cOm, Mainly Located In Asia.

Mean Stiffness And Ultimate Tensile Strength For The 3d Printer Materials Download Table. It has very high heat and impact resistance. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Tensile strength measures the ability of a material to be pulled from both ends and not break. Different 3d printing materials support different combinations of toughness and tensile strength. Each image highlights a sample project that was polycarbonate is known for its strength and durability. All3dp is an editorially independent publication. Materials of high tensile strength are typically found in structural, mechanical, or static components where a breakage is unacceptable, such as during the sla 3d printing process, the components of the resin form covalent bonds providing high degree of lateral strength, but the polymerization. It's the maximum amount of stress the material can take before breaking. 3d printers can print in a multitude of materials though, as there are so many different machines available some many materials are high in tensile strength, like glass or steel, but lack the durability supplied by another material like aluminum which won't shatter or bend in most cases — with bullets. Editorial content, on principle, can not be bought or influenced. Tensile strength is the measurement of a material's resilience. Discover the top 3d printing materials used in the industry today. Select the best material for your select one of the materials below to get started. Tensile strength is typically divided into three categories So let's get on with it and start talking about our materials.