3D Printing Messy Infill. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. 3d printing infill is the secret to stronger and more stable 3d prints. Cheap 3d printer filaments are more likely to result in failed prints despite the best. Editorial content, on principle, can not be bought or influenced. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use.

3D Printing Messy Infill : The Final Setting Of The Infill Ratio Often Depends On The Experience Of A Person Preparing The Files For Printing.

What Infill Should You Use For Your 3d Prints. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Cheap 3d printer filaments are more likely to result in failed prints despite the best. What is infill in 3d printing? Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. All3dp is an editorially independent publication. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. 3d printing infill is the secret to stronger and more stable 3d prints. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Infill provides the 3d print with internal support as the printer builds each layer. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. This type of pattern is also great for printer calibration prints since they take the shortest amount of time.

So remove that concept from your mind.

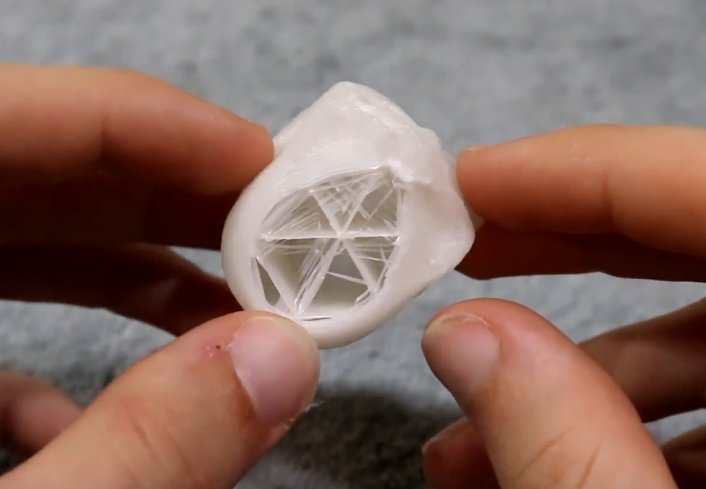

When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. They are least likely to deform and provide the best regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Infill provides the 3d print with internal support as the printer builds each layer. The infill the amount of material that occupies the internal part of the piece. Having an issue where 100% infill is looking real flaky, stringy and thin when i print my file on simplify3d but when i try and slice and print the same file with same basic settings (0.2mm, 60mm/s, 100% infill) on cura the. Hunter626103d printers 3d printing 3d printers. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. I should have mentioned in the op that i am running a sock, and i am running a plated nozzle (e3d nozzle x), though i haven't taken. An understanding on the inside of our prints. Best infill for strength vs material used. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. Moroccan stars and catfill showed poorer performance in terms of strength and while the tests conducted only covered a small range of the possible materials and machines used today in desktop 3d printing, it does offer a. The final setting of the infill ratio often depends on the experience of a person preparing the files for printing. Basically the final 3d printed model will have different infill densities depending on the region of the model. Download files and build them with your 3d printer, laser cutter, or cnc. Editorial content, on principle, can not be bought or influenced. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. The matrix below highlights which combinations work well with each other and which 3d printer filament types do not work together and which materials that can be used as breakaway support. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). 3d print does not stick to the bed. Cheap 3d printer filaments are more likely to result in failed prints despite the best. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. This 3d printer bed leveling tool uses a pulse induction metal detection sensor and a led bar graph to show the relative distanc… As of right now i can choose from a total of 7 different infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Triangular infill is the strongest infill pattern because triangles are the strongest shape. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. An already durable 10% infill is set by default for all our prints. Thingiverse user 'duncan916' uploaded the 'infill percent display' and 'number of shells display' reference tools for anybody that is serious about their thankfully, a number of 3d printing community good samaritans have put together a variety of 3d printable models that enable users to test the. An increase in percentage of infills can be requested if desired. So remove that concept from your mind.

Applied Sciences Free Full Text An Overview Of Material Extrusion Troubleshooting Html : Editorial Content, On Principle, Can Not Be Bought Or Influenced.

Cura Top Layer Ironing Great 3d Printing Top Surface Quality Youtube. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. What is infill in 3d printing? Editorial content, on principle, can not be bought or influenced. 3d printing infill is the secret to stronger and more stable 3d prints. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Cheap 3d printer filaments are more likely to result in failed prints despite the best. Infill provides the 3d print with internal support as the printer builds each layer. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. All3dp is an editorially independent publication.

Weak Infill . There Are A Lot Of Concepts Within The Desktop 3D Printing Space Which Sometimes Are A Bit Complicated To Understand.

Weak Infill. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Infill provides the 3d print with internal support as the printer builds each layer. Cheap 3d printer filaments are more likely to result in failed prints despite the best.

How To 3d Print Center For Applied Research - Basically the final 3d printed model will have different infill densities depending on the region of the model.

Ultimate 3d Print Quality Troubleshooting Guide 2018 All 44 Problems. Infill provides the 3d print with internal support as the printer builds each layer. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. But that happens on the very first top layer. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Editorial content, on principle, can not be bought or influenced. 3d printing infill is the secret to stronger and more stable 3d prints. Cheap 3d printer filaments are more likely to result in failed prints despite the best. What is infill in 3d printing? Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print.

Over Extrusion Of Infill For Narrow Walls Nozzle Grinds Over Print Hardware Firmware And Software Help Prusa3d Forum : Hunter626103D Printers 3D Printing 3D Printers.

Infill Is Rough How To Enhance 3d Printing Stack Exchange. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. What is infill in 3d printing? Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. Editorial content, on principle, can not be bought or influenced. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill provides the 3d print with internal support as the printer builds each layer. 3d printing infill is the secret to stronger and more stable 3d prints. Cheap 3d printer filaments are more likely to result in failed prints despite the best. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill.

3d Printing Infill The Basics Simply Explained All3dp - Low Infill Percentages Reduce Material Use And Make The Object Lighter, While More Infill Makes It More Sold.

3d Printering The Past And Future Of Prusa S Slicer Hackaday. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. But that happens on the very first top layer. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill provides the 3d print with internal support as the printer builds each layer. 3d printing infill is the secret to stronger and more stable 3d prints. Cheap 3d printer filaments are more likely to result in failed prints despite the best.

3d Slicer Settings For Beginners 8 Things You Need To Know All3dp , Thingiverse User 'dUncan916' Uploaded The 'iNfill Percent Display' And 'nUmber Of Shells Display' Reference Tools For Anybody That Is Serious About Their Thankfully, A Number Of 3D Printing Community Good Samaritans Have Put Together A Variety Of 3D Printable Models That Enable Users To Test The.

Troubleshooting Guide To Common 3d Printing Problems All3dp. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Editorial content, on principle, can not be bought or influenced. 3d printing infill is the secret to stronger and more stable 3d prints. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. But that happens on the very first top layer. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. Cheap 3d printer filaments are more likely to result in failed prints despite the best. What is infill in 3d printing?

Poor Surface Above Supports : Furthermore, Hexagonal Infills Start To Look Very Similar To Linear Past 30% Infill.

How To Print Overhangs Bridges And Beyond The 45 Rule No Supports. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. But that happens on the very first top layer. Cheap 3d printer filaments are more likely to result in failed prints despite the best. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. 3d printing infill is the secret to stronger and more stable 3d prints. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Over Extrusion When Printing Lower Layers 3d Printing 3d Printers Talk Manufacturing 3d Hubs . An Increase In Percentage Of Infills Can Be Requested If Desired.

Applied Sciences Free Full Text An Overview Of Material Extrusion Troubleshooting Html. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. Infill provides the 3d print with internal support as the printer builds each layer. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Cheap 3d printer filaments are more likely to result in failed prints despite the best. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. All3dp is an editorially independent publication. But that happens on the very first top layer. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. Editorial content, on principle, can not be bought or influenced. What is infill in 3d printing? 3d printing infill is the secret to stronger and more stable 3d prints. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

How To Prevent Warping . Without Infill, Printing The Top Layers Would Be Very Difficult, As The Plastic Would Sag Over The Empty Parts Of The Print.

Print Troubleshooting Pictorial Guide Reprap. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This type of pattern is also great for printer calibration prints since they take the shortest amount of time. All3dp is an editorially independent publication. Cheap 3d printer filaments are more likely to result in failed prints despite the best. But that happens on the very first top layer. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. 3d printing infill is the secret to stronger and more stable 3d prints. What is infill in 3d printing?

Print Quality Guide - 3D Print Does Not Stick To The Bed.

10 Common 3d Printing Troubleshooting Problems You May Have Dobot. Infill looks fine, it is printing fast, so that is where i would expect the filament to glob to the extruder. Without infill, printing the top layers would be very difficult, as the plastic would sag over the empty parts of the print. Infill provides the 3d print with internal support as the printer builds each layer. But that happens on the very first top layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication. 3d printing infill is the secret to stronger and more stable 3d prints. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. What is infill in 3d printing? We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to printer does not extrude enough plastic, gaps between perimeters and infill. Cheap 3d printer filaments are more likely to result in failed prints despite the best. Infill takes up the empty space within a 3d print to reinforce and increase the the ultimate secret to successful 3d prints lies in the material you use. This type of pattern is also great for printer calibration prints since they take the shortest amount of time.