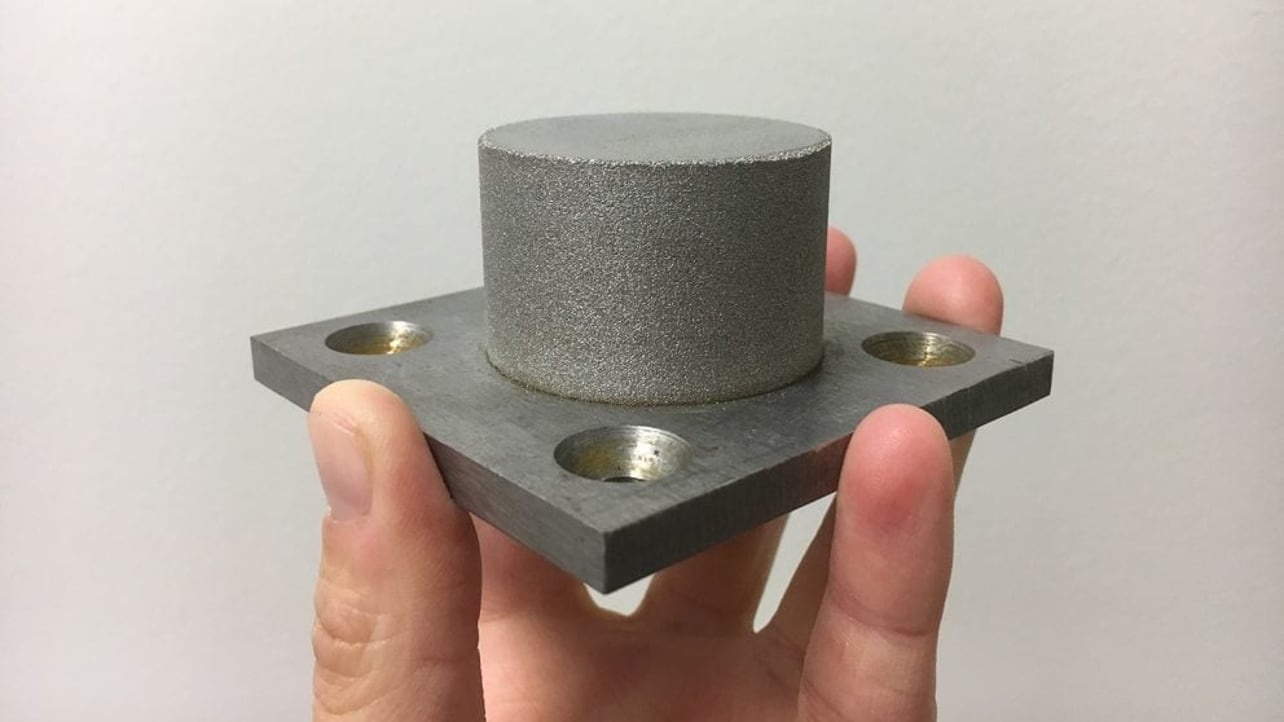

3D Printing Metal Alloys. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Metal am technologies are ultimately constrained by the underlying laws of physics. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. However, this trend is asymptotic. Metal 3d printing is advancing rapidly on all fronts: However, they are more prone to fatigue. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Physics of metal 3d printing. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality.

3D Printing Metal Alloys , Metal Am Technologies Are Ultimately Constrained By The Underlying Laws Of Physics.

Inside The Amplab Zero Gravity 3d Printed Metal And The Future Of Materials 3d Printing Industry. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. However, they are more prone to fatigue. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Physics of metal 3d printing. Metal 3d printing is advancing rapidly on all fronts: Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. However, this trend is asymptotic. Metal am technologies are ultimately constrained by the underlying laws of physics.

This is especially true with complex or intricate designs which would present a challenge to traditional manufacture.

In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Additive manufacturing of new england. Metal 3d printing services located in middletown. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Its main advantage lies in a continuous expansion in the range of metals, alloys and metallic composites which can be produced in this technology. However, they are more prone to fatigue. Metal 3d printing services located in middletown, ct. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. When casting metal alloys, the element with the highest melting point starts to solidify first. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. The growth of additive manufacturing is tied to business opportunities and, directly, the materials available and their cost. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. In terms of the materials that can be used in 3d metal printing approaches, the number of metals is growing and include aluminium, copper, gold, platinum, titanium and various metal alloys. Metal 3d printing, also known as direct metal laser sintering (dmls) and direct metal laser melting (dmlm) is an additive layer technology. 3d printing in metals via dmls is an additive manufacturing process which can work out more cost effective than traditional 'subtractive' processes. Mainly used for precious jewelry. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Key applications of metal 3d printing. Metal 3d printing has become a continuous trend in the industry. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial. The mims industry has been around for decades which means the metal powders that have now bee adapted for 3d printing are well established. A combination of high strength, low weight and excellent biocompatibility define titanium alloys. We offer a full post build machining and. The top countries of suppliers are india, china, and. By doing this, you will have a. The 3d printing metals market comprises multiple different printer technologies. Find out how 3d printing metal works and how you can create designs infused with metal powder! When metal 3d printing it is critical for final part. However, this trend is asymptotic. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper.

Exone Introduce New Nickel Based Inconel R Alloy 625 For 3d Metal Printers 3dprint Com The Voice Of 3d Printing Additive Manufacturing - Uses The Same Process As Sls But Is Used When Referring To The Process Of Sintering Metal Alloys Vs.

Engineers Develop Gallium Alloy Paste To 3d Print Soft Robotics Design Engineering. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Metal 3d printing is advancing rapidly on all fronts: However, this trend is asymptotic. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. However, they are more prone to fatigue. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal am technologies are ultimately constrained by the underlying laws of physics. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Physics of metal 3d printing. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments.

Watch High Speed Metal 3d Printing In New Digital Alloys Video 3d Printing Industry . The Technology Is Becoming More Advanced, Print Speeds Are Increasing And There Is A Greater Range Of Although Its Commercial Release Won't Be Until 2020, Digital Alloys' Patented Joule Printing Technology Is Another Metal 3D Printing Process Worth.

Iro3d Lowers The Cost Of 3d Metal Printing With A 5 000 Machine 3dnatives. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal am technologies are ultimately constrained by the underlying laws of physics. Metal 3d printing is advancing rapidly on all fronts: Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data.

U S Army Adapts Military Grade Steel Alloy For 3d Printing Ultra Strong Parts 3d Printing Media Network The Pulse Of The Am Industry - Making metal 3d printing better.

Exone Adds New Stainless Steel Alloy To Metal 3d Printing Material Offerings. However, they are more prone to fatigue. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Physics of metal 3d printing. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal 3d printing is advancing rapidly on all fronts: Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. Metal am technologies are ultimately constrained by the underlying laws of physics. However, this trend is asymptotic. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper.

Exone Adds New Stainless Steel Alloy To Metal 3d Printing Material Offerings : Metal 3D Printing Is Advancing Rapidly On All Fronts:

Gold 3d Printing Explained Technology Material Tips 3d Printing Blog I Materialise. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal 3d printing is advancing rapidly on all fronts: For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. However, this trend is asymptotic. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Physics of metal 3d printing. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. However, they are more prone to fatigue. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Metal am technologies are ultimately constrained by the underlying laws of physics.

A New Copper Titanium Alloy Enables 3d Printing Advanced Science News . The Technology Is Becoming More Advanced, Print Speeds Are Increasing And There Is A Greater Range Of Although Its Commercial Release Won't Be Until 2020, Digital Alloys' Patented Joule Printing Technology Is Another Metal 3D Printing Process Worth.

2020 Metal 3d Printer Buyer S Guide All3dp Pro. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. However, this trend is asymptotic. However, they are more prone to fatigue. Metal am technologies are ultimately constrained by the underlying laws of physics. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Physics of metal 3d printing. Metal 3d printing is advancing rapidly on all fronts: The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam.

Inside The Amplab Zero Gravity 3d Printed Metal And The Future Of Materials 3d Printing Industry . However, This Trend Is Asymptotic.

A New Copper Titanium Alloy Enables 3d Printing Advanced Science News. Physics of metal 3d printing. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. Metal 3d printing is advancing rapidly on all fronts: For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Metal am technologies are ultimately constrained by the underlying laws of physics. However, they are more prone to fatigue. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. However, this trend is asymptotic. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality.

3d Printing In Aluminum Dmls And Ebm 3d Print Service Beamler . Cold Spray Metal Printing Cold Spray Metal Printing Was Originally Used By Nasa To Build Metal Objects In Space.

Comparison Of The Most Widely Accepted Slm Technologies Of 3d Printing Download Table. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal 3d printing is advancing rapidly on all fronts: For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. However, this trend is asymptotic. Physics of metal 3d printing. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal am technologies are ultimately constrained by the underlying laws of physics. However, they are more prone to fatigue.

Velo3d Qualifies Hastelloy X Alloy For 3d Printing Applications In Power Generation Tct Magazine , 3D Printing In Metals Via Dmls Is An Additive Manufacturing Process Which Can Work Out More Cost Effective Than Traditional 'sUbtractive' Processes.

The Us Army Transforms A Steel Alloy To 3d Print Ultra Resistant Parts 3dnatives. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. However, they are more prone to fatigue. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Metal am technologies are ultimately constrained by the underlying laws of physics. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Physics of metal 3d printing. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Metal 3d printing is advancing rapidly on all fronts: However, this trend is asymptotic. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality.

Metal Alloy Parts Developed Through 3d Printing By New Research , Metal Additive Manufacturing (Am) Processes Continue To Improve In Speed, Cost, Efficiency, And Part Quality.

Finding The Sweet Spot In Metal 3d Printing Digital Engineering 24 7. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. However, they are more prone to fatigue. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. However, this trend is asymptotic. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal am technologies are ultimately constrained by the underlying laws of physics. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Physics of metal 3d printing.

Chinese Scientists Unveil Liquid Phase 3 D Printing Method Using Low Melting Metal Alloy Ink Innovations Report , These Metal 3D Printing Materials Are High Quality Alloys That Have An Established Supply Chain And Proved Process Controls.

Smartech Releases Reports On Aluminum Alloy 3d Printing And The Automotive Am Market 3d Science Valley. Metal 3d printing or metal additive manufacturing is a revolutionary technology which produces components directly from 3d cad data. However, this trend is asymptotic. For example, take a look at the mechanical properties of the alsi10mg eos metal 3d printing alloy and the a360 die. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. The technology is becoming more advanced, print speeds are increasing and there is a greater range of although its commercial release won't be until 2020, digital alloys' patented joule printing technology is another metal 3d printing process worth. In addition to more common metals, 3d printers can also fabricate parts out of alloys uniquely suited for hostile environments. Metal additive manufacturing (am) processes continue to improve in speed, cost, efficiency, and part quality. However, they are more prone to fatigue. Metal 3d printing is advancing rapidly on all fronts: With the help of metal 3d printing, weight of the launch vehicle can be decreased drastically. Metal printed parts have higher strength and hardness and are often more flexible than parts that are manufactured using a traditional method. Physics of metal 3d printing. Metal 3d printing is useful for parts that are tricky to machine, either in complexity or material, because especially at low volumes it can be cheaper. Metal am technologies are ultimately constrained by the underlying laws of physics.