3D Printing Metal Laser. This italian metal 3d printer is one of sisma's latest releases. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. 3d printing isn't just confined to plastic. It is equipped with two overlapping. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Laser metal deposition lmd is in many ways similar to melting technologies. This process involves metals such as gold, platinum, or silver to. The two technologies have a lot of similarities: The build begins with dispensing a thin layer of metal powder. How much does a metal 3d printer cost? Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built.

3D Printing Metal Laser . Selective Laser Melting (Slm), Also Known As Direct Metal Laser Melting (Dmlm) Or Laser Powder Bed Fusion (Lpbf), Is A Rapid Prototyping, 3D Printing, Or Additive Manufacturing (Am).

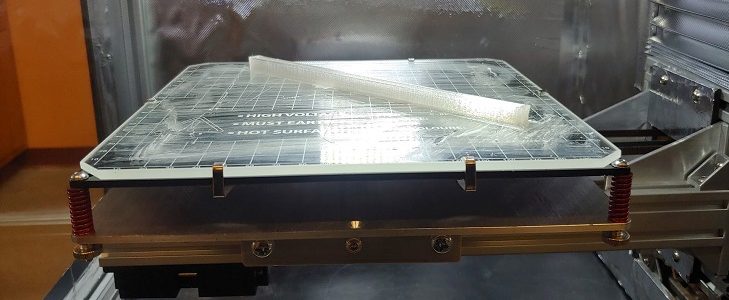

Laser Sintering Machine For Metal 3d Printer Printing Metal Stock Photo Download Image Now Istock. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Laser metal deposition lmd is in many ways similar to melting technologies. 3d printing isn't just confined to plastic. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. This process involves metals such as gold, platinum, or silver to. This italian metal 3d printer is one of sisma's latest releases. The two technologies have a lot of similarities: Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. How much does a metal 3d printer cost? 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. The build begins with dispensing a thin layer of metal powder. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. It is equipped with two overlapping. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers.

Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family.

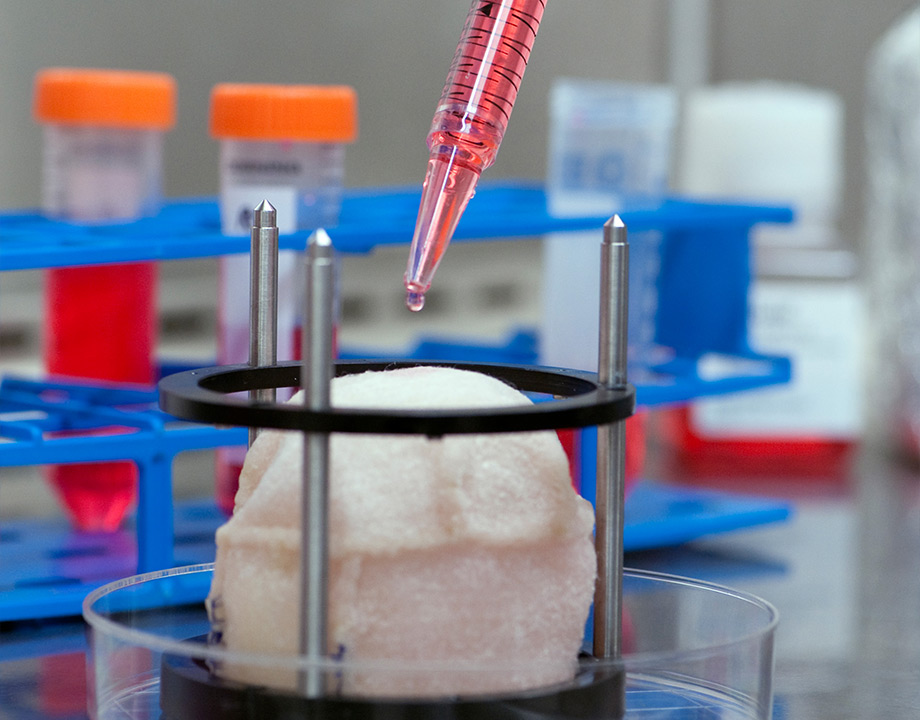

Selective laser melting (slm), also known as direct metal laser melting (dmlm) or laser powder bed fusion (lpbf), is a rapid prototyping, 3d printing, or additive manufacturing (am). Metal 3d printing takes flight. It's titanium and took about 40 hours to print metal printing is already in use. Direct metal laser sintering and selective laser melting are two of the more industrial methods of 3d printing. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Laser metal deposition lmd is in many ways similar to melting technologies. Similar to ink printing on paper. 3d metal printing is an emerging additive laser metal sintering (3d laser metal printing) manufacturing technology with a presence in numerous industries including medical, aerospace, automotive, and defense. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. Metal powder is the backbone of metal 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal as both machines use metal powder and a laser, parts printed with ded are very similar to those printed by slm with one key exception: They are used, as the name suggests, to 3d print object in metal. 3d printing isn't just confined to plastic. The core of the unit is three independent modules, the dose module, the build module and the overflow module. Direct metal laser melting creates parts that are 99. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Metal 3d printing has been one of the most outstanding developments in the am industry in recent years. This technology is also known as direct metal laser. Advantages to this process include all metal powders are sourced from renishaw and are formulated specifically for our printer. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. The dominant form of metal 3d printing is powder bed fusion, in which an energy source—a laser in the case of selective laser melting (slm) or an electron beam in electron beam manufacturing (ebm)—fuses particles of metal powder together point by point. The build begins with dispensing a thin layer of metal powder. Both use a laser to scan and selectively fuse (or melt). Selective laser melting (slm), also known as direct metal laser melting (dmlm) or laser powder bed fusion (lpbf), is a rapid prototyping, 3d printing, or additive manufacturing (am). The main procedure for both methods is similar. I wouldn't have been able to pick it out as laser printed. Designed to boost metal 3d printing, the m line factory production unit offers a maximum build envelope of 400 x 400 x 425 mm³ and is optionally equipped with 1 to 4 laser sources. This process involves metals such as gold, platinum, or silver to.

Protolabs Launches Production Capabilities For Metal 3d Printing Business Wire , A Moving Arm Pushes Metal Particles Across The Printing Area.

Scientists Create Device That Can 3d Print Metal Objects In Mid Air The Science Explorer. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. The two technologies have a lot of similarities: The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. 3d printing isn't just confined to plastic. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. It is equipped with two overlapping. This process involves metals such as gold, platinum, or silver to. This italian metal 3d printer is one of sisma's latest releases. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Laser metal deposition lmd is in many ways similar to melting technologies. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. The build begins with dispensing a thin layer of metal powder. How much does a metal 3d printer cost?

What Is Metal 3d Printing Youtube : The Core Of The Unit Is Three Independent Modules, The Dose Module, The Build Module And The Overflow Module.

Types Of 3d Printing In Metal. The two technologies have a lot of similarities: This italian metal 3d printer is one of sisma's latest releases. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. It is equipped with two overlapping. 3d printing isn't just confined to plastic. How much does a metal 3d printer cost? Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. The build begins with dispensing a thin layer of metal powder. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel.

10 Rising Stars In Metal 3d Printing Hardware Amfg - They are used, as the name suggests, to 3d print object in metal.

Metal 3d Printing For Production Parts Protolabs. Laser metal deposition lmd is in many ways similar to melting technologies. This process involves metals such as gold, platinum, or silver to. How much does a metal 3d printer cost? 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. This italian metal 3d printer is one of sisma's latest releases. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. The build begins with dispensing a thin layer of metal powder. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. It is equipped with two overlapping. The two technologies have a lot of similarities: Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. 3d printing isn't just confined to plastic.

The All Metal Trinus 3d Printer To Hit Kickstarter Starting At 199 3d Printing Industry . How Much Does A Metal 3D Printer Cost?

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcswxt8dgzpq60owda0nmknc4sm4skssghp Ig Usqp Cau. This italian metal 3d printer is one of sisma's latest releases. It is equipped with two overlapping. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. This process involves metals such as gold, platinum, or silver to. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. The build begins with dispensing a thin layer of metal powder. 3d printing isn't just confined to plastic. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. How much does a metal 3d printer cost? The two technologies have a lot of similarities: The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Laser metal deposition lmd is in many ways similar to melting technologies.

7 Issues To Look Out For In Metal 3d Printing Engineering Com : Laser Metal Deposition Lmd Is In Many Ways Similar To Melting Technologies.

A Gigantic Multi Material 3d Metal Printer Fabbaloo. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. How much does a metal 3d printer cost? Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Laser metal deposition lmd is in many ways similar to melting technologies. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. The two technologies have a lot of similarities: This italian metal 3d printer is one of sisma's latest releases. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. 3d printing isn't just confined to plastic. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. The build begins with dispensing a thin layer of metal powder. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. This process involves metals such as gold, platinum, or silver to. It is equipped with two overlapping.

Metal 3d Printer Dmls Printer Additive Manufacturing Systems : Selective Laser Melting And Direct Metal Laser Sintering.

Selective Laser Melting Slm 3d Printing Simply Explained All3dp. Laser metal deposition lmd is in many ways similar to melting technologies. The build begins with dispensing a thin layer of metal powder. This italian metal 3d printer is one of sisma's latest releases. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. How much does a metal 3d printer cost? This process involves metals such as gold, platinum, or silver to. It is equipped with two overlapping. The two technologies have a lot of similarities: 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. 3d printing isn't just confined to plastic. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser.

Slm Selective Laser Melting 3d Printing Metal - Direct Metal Laser Melting Creates Parts That Are 99.

How To Design For 3d Printing With Direct Metal Laser Sintering Machine Design. It is equipped with two overlapping. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. Laser metal deposition lmd is in many ways similar to melting technologies. The two technologies have a lot of similarities: Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. The build begins with dispensing a thin layer of metal powder. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. This italian metal 3d printer is one of sisma's latest releases. 3d printing isn't just confined to plastic. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. This process involves metals such as gold, platinum, or silver to. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. How much does a metal 3d printer cost? Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use.

Metal 3d Printing Design Guidelines Design Engineering , The Printed Manifold On Display Is Just Fantastic.

Metal 3d Printing A Definitive Guide 2019 Amfg. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. How much does a metal 3d printer cost? The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Laser metal deposition lmd is in many ways similar to melting technologies. The two technologies have a lot of similarities: Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. This italian metal 3d printer is one of sisma's latest releases. The build begins with dispensing a thin layer of metal powder. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. It is equipped with two overlapping. This process involves metals such as gold, platinum, or silver to. 3d printing isn't just confined to plastic. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser.

Slm 3d Printing Advantages And Applications Beamler - This Italian Metal 3D Printer Is One Of Sisma's Latest Releases.

Direct Metal Laser Sintering Dmls Aluminum 3d Printing. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. The build begins with dispensing a thin layer of metal powder. How much does a metal 3d printer cost? Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. 3d printing isn't just confined to plastic. It is equipped with two overlapping. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. The two technologies have a lot of similarities: This process involves metals such as gold, platinum, or silver to. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. Laser metal deposition lmd is in many ways similar to melting technologies. This italian metal 3d printer is one of sisma's latest releases.

Snapmaker Original 3 In 1 3d Printer 3d Printing Cnc Carving Laser Engraving All Metal Entry Level Digital Tool Easy To Use Software Upgraded Version Printing Volume 4 9 X4 9 X4 9 Amazon Com Industrial Scientific , The Build Begins With Dispensing A Thin Layer Of Metal Powder.

3d Printing With Metal The Final Frontier Of Additive Manufacturing Extremetech. This process involves metals such as gold, platinum, or silver to. Direct metal laser sintering was patented by erd and eos back in 1994, before eos pioneered the technology in their dmls 3d printers. Simply put, the 3d printer creates objects out of a bed of powdered metal by using a powerful laser. Learn all about direct metal laser sintering, one of few 3d printing technologies capable of making parts directly the printer uses an inert gas, which protects the heated powder and part as it is built. The two technologies have a lot of similarities: Laser metal deposition lmd is in many ways similar to melting technologies. The build begins with dispensing a thin layer of metal powder. The technology deposits powders and uses lasers to heat them into shape metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Selective laser melting (slm) and direct metal laser sintering (dmls) are two metal additive manufacturing processes that belong to the powder bed fusion 3d printing family. 3d printing isn't just confined to plastic. Direct metal laser sintering can also be used with precious metals to create 3d printed jewelry. 3d printed examples in bronze, direct from stl cad models, other materials available like silver, gold, titanium, cobalt chrome and stainless steel. This italian metal 3d printer is one of sisma's latest releases. How much does a metal 3d printer cost? It is equipped with two overlapping.