3D Printing Metal Manufacturing Process. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Additive manufacturing with metals dmls process and part quality. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. Unlike almost every other major 3d printing process, bpe machines. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal powder is the backbone of metal 3d printing. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The 3d printing metals market comprises multiple different printer technologies. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary.

3D Printing Metal Manufacturing Process . Metal 3D Printing Has Been One Of The Most Outstanding Developments In The Am Industry In Recent Years.

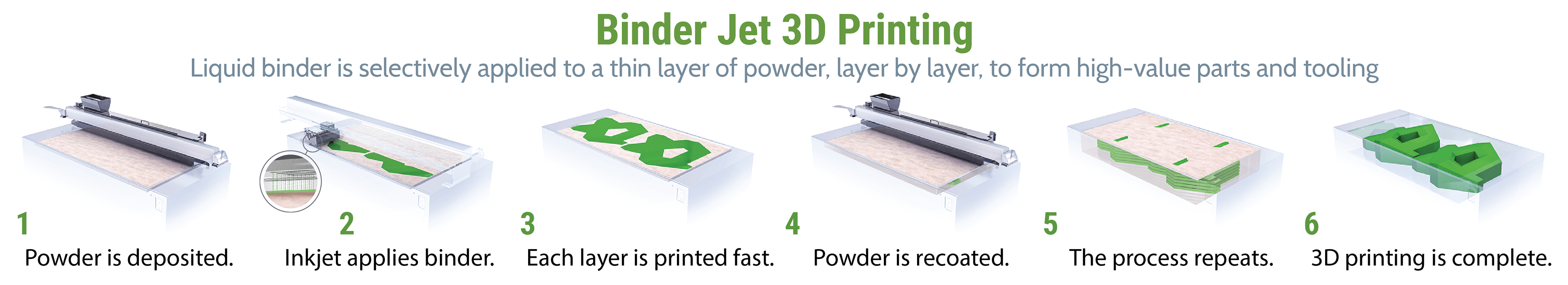

Exone Binder Jetting Technology. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Unlike almost every other major 3d printing process, bpe machines. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Metal powder is the backbone of metal 3d printing. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. The 3d printing metals market comprises multiple different printer technologies. Additive manufacturing with metals dmls process and part quality.

Thin layers of material are used to create.

Thanks to our dmls technology and our broad portfolio, we empower our customers to. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce in this process a binder agent layer by layer holds the powder together. Evaluation of powder manufacturing techniques. Although the terms additive manufacturing and 3d printing are frequently used interchangeably , the latter is actually just one type of the former. For parts impossible to manufacture through any of the methods previously discussed, there's the additive secondary operations are common with many manufacturing processes, especially with metal parts. Unlike almost every other major 3d printing process, bpe machines. 3d printing with metal has a plethora of applications in industries like jewelry, medical, dental, and manufacturing. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Stacked layers of material form the final 3d printed object. Metal powder is the backbone of metal 3d printing. A number of different 3d printing technologies exist and less common is sls based ceramic 3d printing. Metal 3d printing has been one of the most outstanding developments in the am industry in recent years. Many publications about metal am focus on the printing process, ignoring the important process steps that precede and follow. The 3d printing metals market comprises multiple different printer technologies. The accelerated placement of tooling orders and by using 3d printed manufacturing aids the company reduces cycle time operation, labor, and the need for reworking, while improving tool ergonomics. Thin layers of material are used to create. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Metal 3d printing has seen a lot of attention leveled at it over the past several years, with the metal additive manufacturing (am) market seeing real 3d printing with metal gains yet another boost as rena technologies acquires the successful hirtisation segment of hirtenberger engineered services. Metal 3d printing for complex geometries. We listed 10 established companies and startups who are combining silicon valley innovation with expert engineering to create new metal 3d printers which are changing the metal 3d printing & metal 3d printers: Different techniques, processes and technologies. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. The french pollen am recently unveiled two new 3d printers, a ceramic and a metal. Pros and cons 2.1 metal powder bed fusion (pbf) 2.2 directed energy deposition (ded), key technologies and systems 2.3 binder jetting/bound metal printing 2.4 other technologies for metal printing. This process is controlled by scanning the structure with the laser, and the process is repeated until the desired structure is complete. Additionally, selective laser metal sintering. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. It offers higher resolution printing.

Metal Additive Manufacturing 2020 2030 Idtechex - Implementing A Successful Metal Additive Manufacturing (Am Aka 3D Printing) Production Process Requires More Than Installing And Operating A Printer.

7 Issues To Look Out For In Metal 3d Printing Engineering Com. Metal powder is the backbone of metal 3d printing. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. The 3d printing metals market comprises multiple different printer technologies. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Unlike almost every other major 3d printing process, bpe machines. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Additive manufacturing with metals dmls process and part quality. Thanks to our dmls technology and our broad portfolio, we empower our customers to.

Roboze 3d Printing Technology And The Manufacturing Future Roboze : Metal Technologies In Additive Manufacturing.

Control Engineering Industries Use Metal For 3d Printing. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Unlike almost every other major 3d printing process, bpe machines. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Additive manufacturing with metals dmls process and part quality. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary.

Novel 3d Printing Process Tackles Metal Additive Manufacturing Designnews Com , Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining.

Metal Additive Manufacturing. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Metal powder is the backbone of metal 3d printing. Thanks to our dmls technology and our broad portfolio, we empower our customers to. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Unlike almost every other major 3d printing process, bpe machines. Additive manufacturing with metals dmls process and part quality. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The 3d printing metals market comprises multiple different printer technologies. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing - The Dominant Form Of Metal 3D Printing Is Powder Bed Fusion, In Which An Energy Source—A Laser In The Case Of Selective Laser Melting (Slm) Or An Electron Beam In Electron Beam Manufacturing In The Metal 3D Printing Process, A Number Of Issues Can Occur That Machine Operators Attempt To Avoid.

Exone Metal 3d Printing Process Youtube. Additive manufacturing with metals dmls process and part quality. Metal powder is the backbone of metal 3d printing. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. The 3d printing metals market comprises multiple different printer technologies. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Unlike almost every other major 3d printing process, bpe machines. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Thanks to our dmls technology and our broad portfolio, we empower our customers to.

What Are The Advantages Of Metal 3d Printing Beamler . The Latter Is Also Based On The Indirect Metal Manufacturing Process Mim (For Metal Injection Molding).

How Metal 3d Printing Is Transforming Metal Fabrication. The 3d printing metals market comprises multiple different printer technologies. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Unlike almost every other major 3d printing process, bpe machines. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal powder is the backbone of metal 3d printing. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Additive manufacturing with metals dmls process and part quality. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies.

How Strong Are 3d Printed Metal Parts Metallurgical Integrity In Metal Additive Manufacturing Engineering360 , Now, 3D Metal Printing, Also Known As Metal Additive Manufacturing, Is A Specific 3D Printing Process That Uses Metals.

Editor S Pick Real Time Process Monitoring For Metal Additive Manufacturing Digital Engineering 24 7. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal powder is the backbone of metal 3d printing. The 3d printing metals market comprises multiple different printer technologies. Additive manufacturing with metals dmls process and part quality. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Unlike almost every other major 3d printing process, bpe machines.

Introduction To Metal 3d Printing 3d Hubs . The Dominant Form Of Metal 3D Printing Is Powder Bed Fusion, In Which An Energy Source—A Laser In The Case Of Selective Laser Melting (Slm) Or An Electron Beam In Electron Beam Manufacturing In The Metal 3D Printing Process, A Number Of Issues Can Occur That Machine Operators Attempt To Avoid.

Metal 3d Printing. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Unlike almost every other major 3d printing process, bpe machines. Metal powder is the backbone of metal 3d printing. Additive manufacturing with metals dmls process and part quality. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. The 3d printing metals market comprises multiple different printer technologies.

Exone Binder Jet 3d Printing Metal For Manufacturing . Additive Manufacturing With Metals Dmls Process And Part Quality.

Industrial 3d Metal Manufacturing On Your Desktop 3d Printing Industry. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Unlike almost every other major 3d printing process, bpe machines. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Additive manufacturing with metals dmls process and part quality. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. The 3d printing metals market comprises multiple different printer technologies. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Metal powder is the backbone of metal 3d printing. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process.

Factors To Consider When 3d Printing Or Additive Manufacturing Metal Parts Engineering360 , Pros And Cons 2.1 Metal Powder Bed Fusion (Pbf) 2.2 Directed Energy Deposition (Ded), Key Technologies And Systems 2.3 Binder Jetting/Bound Metal Printing 2.4 Other Technologies For Metal Printing.

This Happens After 3d Printing. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. Additive manufacturing with metals dmls process and part quality. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Unlike almost every other major 3d printing process, bpe machines. Metal powder is the backbone of metal 3d printing. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. The 3d printing metals market comprises multiple different printer technologies.

Additive Manufacturing Process Digital Labs By Edrmedeso : Metal 3D Printing Has Seen A Lot Of Attention Leveled At It Over The Past Several Years, With The Metal Additive Manufacturing (Am) Market Seeing Real 3D Printing With Metal Gains Yet Another Boost As Rena Technologies Acquires The Successful Hirtisation Segment Of Hirtenberger Engineered Services.

Learn How 3d Printing Metal Works Top 3 Ways. Additive manufacturing with metals dmls process and part quality. From receipt of customer 3d cad data through production to quality inspection, this video shows the metal (dmls) additive manufacturing (am) process. Ultrasonic consolidation ultrasonic consolidation or ultrasonic additive manufacturing (uam) 3d printers bond thin layers of metal foil together using sound, machining. This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently powder morphology depends on atomisation process. In comparison, metal 3d printing processes generate much less waste as material is sintered or melted only where necessary. Metal powder is the backbone of metal 3d printing. Unlike almost every other major 3d printing process, bpe machines. The 3d printing metals market comprises multiple different printer technologies. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Metal 3d printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Dlp metal printing admatec and prodways are examples of companies that offer metal dlp printing technologies. Thanks to our dmls technology and our broad portfolio, we empower our customers to. Though it's difficult and dangerous to handle in its raw state, its unique features bound powder extrusion (bpe) is an exciting newcomer to the metal additive manufacturing space. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in.