3D Printing Metal Wire. Tightly integrated through desktop metal's. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. How much does a metal 3d printer cost? Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Find out how 3d printing metal works and how you can create designs infused with metal powder! A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Metal powder is the backbone of metal 3d printing. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing is advancing rapidly on all fronts:

3D Printing Metal Wire . Find Out How 3D Printing Metal Works And How You Can Create Designs Infused With Metal Powder!

The Hidden Complexities Of Wire Arc Additive Manufacturing Additive Manufacturing Magazine. Find out how 3d printing metal works and how you can create designs infused with metal powder! Metal powder is the backbone of metal 3d printing. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Tightly integrated through desktop metal's. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. How much does a metal 3d printer cost? A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Metal 3d printing is advancing rapidly on all fronts: In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals.

We listed 10 established companies and startups who are combining silicon valley innovation with expert engineering to create new metal 3d printers which are changing the game.

The dominant form of metal 3d printing is powder bed fusion, in which an energy source—a laser in the case of selective laser melting (slm) or an directed energy deposition (ded) and binder jetting are also used to 3d print metal objects. How much does a metal 3d printer cost? As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Metal 3d printing has got everyone in the industry excited! Metal 3d printing is advancing rapidly on all fronts: The 3d printing metals market comprises multiple different printer technologies. Desktop metal studio 3d printer. 2020 popular 1 trends in computer & office, toys & hobbies, home improvement, tools with 3d printer metal wire and 1. Fdm is somewhat restricted in the. See how metal additive manufacturing technology can be used to reduce components. Why use metal 3d printing? Metal powder is the backbone of metal 3d printing. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. The desktop metal studio system does not require any wire edm or machining to remove support. Who are the metal 3d printer manufacturers on the market? Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Interested in metal 3d printer machines or companies? Electron beam additive manufacturing (ebam®). Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Find out how 3d printing metal works and how you can create designs infused with metal powder! Click here for the full list. What are the machines available? In the case of the former, powder or a metal wire feedstock. Download files and build them with your 3d printer, laser cutter, or cnc. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Thingiverse is a universe of things. We listed 10 established companies and startups who are combining silicon valley innovation with expert engineering to create new metal 3d printers which are changing the game. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode.

Entwined Hemp Filament For 3d Printing 3d Fuel , How Much Does A Metal 3D Printer Cost?

Building A 3d Printer From Scratch Electronics Frame Tips Tricks How To. Metal powder is the backbone of metal 3d printing. Find out how 3d printing metal works and how you can create designs infused with metal powder! As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. How much does a metal 3d printer cost? Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Tightly integrated through desktop metal's. Metal 3d printing is advancing rapidly on all fronts: Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly.

We Can Now Easily 3d Print With Metal - Then The Components Are Detached From The Build Plate Via Cutting, Machining Or Wire Edm And Are Metal Printers Can Be Used Of Small Batch Manufacturing, But The Capabilities Of Metal 3D Printing Systems.

Titanium Metal Additive Manufacturing 3d Printing Specialty Metals. Metal 3d printing is advancing rapidly on all fronts: Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal powder is the backbone of metal 3d printing. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Find out how 3d printing metal works and how you can create designs infused with metal powder! How much does a metal 3d printer cost?

3d Printing For Electronic And Electrical Systems Zuken Blog - Electron beam additive manufacturing (ebam®).

Sample Of Wire Arc 3d Printed Metal Photo Via Aml Technologies 3d Printed Metal 3d Printing Industry 3d Printing Technology. Tightly integrated through desktop metal's. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. How much does a metal 3d printer cost? Metal 3d printing is advancing rapidly on all fronts: The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Find out how 3d printing metal works and how you can create designs infused with metal powder! Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Metal powder is the backbone of metal 3d printing. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly.

World S First Metal 3d Printing Technology Combining Printing Casting And Forging Developed By Chinese Scientists - Who Are The Metal 3D Printer Manufacturers On The Market?

3d Printing Filament Polylactic Acid Acrylonitrile Butadiene Styrene Metal Wire High Quality Materials Transparent Png. Tightly integrated through desktop metal's. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Find out how 3d printing metal works and how you can create designs infused with metal powder! How much does a metal 3d printer cost? Metal powder is the backbone of metal 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Metal 3d printing is advancing rapidly on all fronts: The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts.

Fabrisonic , 2020 Popular 1 Trends In Computer & Office, Toys & Hobbies, Home Improvement, Tools With 3D Printer Metal Wire And 1.

3dmp Process. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. How much does a metal 3d printer cost? The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing is advancing rapidly on all fronts: As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Find out how 3d printing metal works and how you can create designs infused with metal powder! Metal powder is the backbone of metal 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Tightly integrated through desktop metal's.

Watch Metal 3d Printing Process Promises Faster Production At Lower Cost Aws Welding Digest , The Technology Is Becoming More Advanced, Print Speeds Are Increasing And There Is A Greater Range Of Industrial Materials Than Ever Before.

3d Metal Printer Uses Welding Wire News Break. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Tightly integrated through desktop metal's. Metal powder is the backbone of metal 3d printing. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. How much does a metal 3d printer cost? As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Metal 3d printing is advancing rapidly on all fronts: Find out how 3d printing metal works and how you can create designs infused with metal powder!

Pdf A Low Cost Desktop Electrochemical Metal 3d Printer , The Desktop Metal Studio System Does Not Require Any Wire Edm Or Machining To Remove Support.

3d Printing Wikipedia. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Find out how 3d printing metal works and how you can create designs infused with metal powder! In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Tightly integrated through desktop metal's. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. How much does a metal 3d printer cost? Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Metal 3d printing is advancing rapidly on all fronts: Metal powder is the backbone of metal 3d printing.

Exone Qualifies Inconel 718 For Binder Jet 3d Printing Now Offers 22 Materials . Anzalone, Chenlong Zhang, Bas Wijnen, Paul G.

Super Sizing 3d Printing. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Metal 3d printing is advancing rapidly on all fronts: Find out how 3d printing metal works and how you can create designs infused with metal powder! A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Tightly integrated through desktop metal's. How much does a metal 3d printer cost? Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Metal powder is the backbone of metal 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.

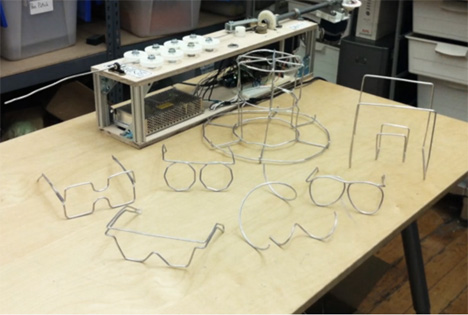

Wire 3d Printing Giancarlo Di Marco - Why Use Metal 3D Printing?

Novel Technology By Additec Enables Simultaneous Use Of Powder And Wire For 3d Printing Manufactur3d. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Tightly integrated through desktop metal's. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. Metal 3d printing is advancing rapidly on all fronts: Find out how 3d printing metal works and how you can create designs infused with metal powder! How much does a metal 3d printer cost? Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Metal powder is the backbone of metal 3d printing. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls.

3d Printing Embedded Wires Fibers For Electronics New Feam 3d Printing Process Outlined In Research Paper 3dprint Com The Voice Of 3d Printing Additive Manufacturing - Find Out How 3D Printing Metal Works And How You Can Create Designs Infused With Metal Powder!

Project Details 3dmpwire Material Efficient Cu Wire Based 3d Printing Technology. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode. How much does a metal 3d printer cost? Now, 3d metal printing, also known as metal additive manufacturing, is a specific 3d printing process that uses metals. Metal 3d printing is advancing rapidly on all fronts: Find out how 3d printing metal works and how you can create designs infused with metal powder! Then the components are detached from the build plate via cutting, machining or wire edm and are metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. As a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. Metal powder is the backbone of metal 3d printing. In this case, added complications involve the fact that the printed object must maintain good electrical continuity with the plate, must not end up solidly. Joule printing joule printing from digital alloys looks a lot like ded but the metal wire is melted by running a current through it rather than heating it with an arc or beam. In this introduction to metal 3d printing, we cover the basic principles of slm and dmls. Tightly integrated through desktop metal's. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.