3D Printing No Infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This video is a quick and easy method for reducing filament usage by reducing infill. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. So what's the smallest % infill you have found you can get away with? It's a simple trick, and the prints come out nice! The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? I noticed that dropping the infill can dramatically reduce plastic consumption. Infill provides the 3d print with internal support as the printer builds each layer.

3D Printing No Infill , Infill Percentage Has An Impact On Strength When Increasing This Parameter It's Set During The Preparation Of A Part For Printing.

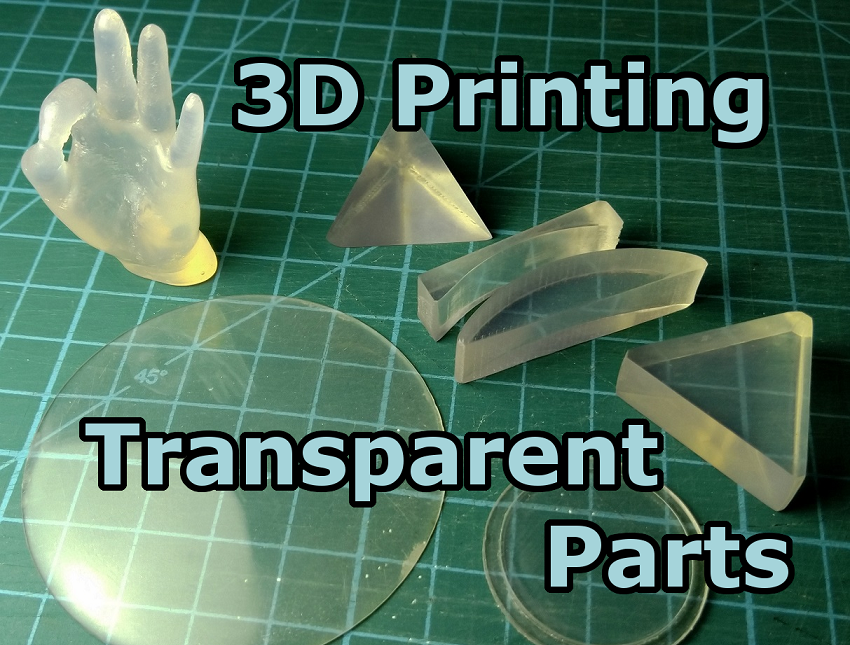

How To Strengthen 3d Printed Parts In Sla Dlp Lcd. It's a simple trick, and the prints come out nice! Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication. So what's the smallest % infill you have found you can get away with? This video is a quick and easy method for reducing filament usage by reducing infill. I noticed that dropping the infill can dramatically reduce plastic consumption. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product.

The infill in 3d printing can be carried out with the following types:

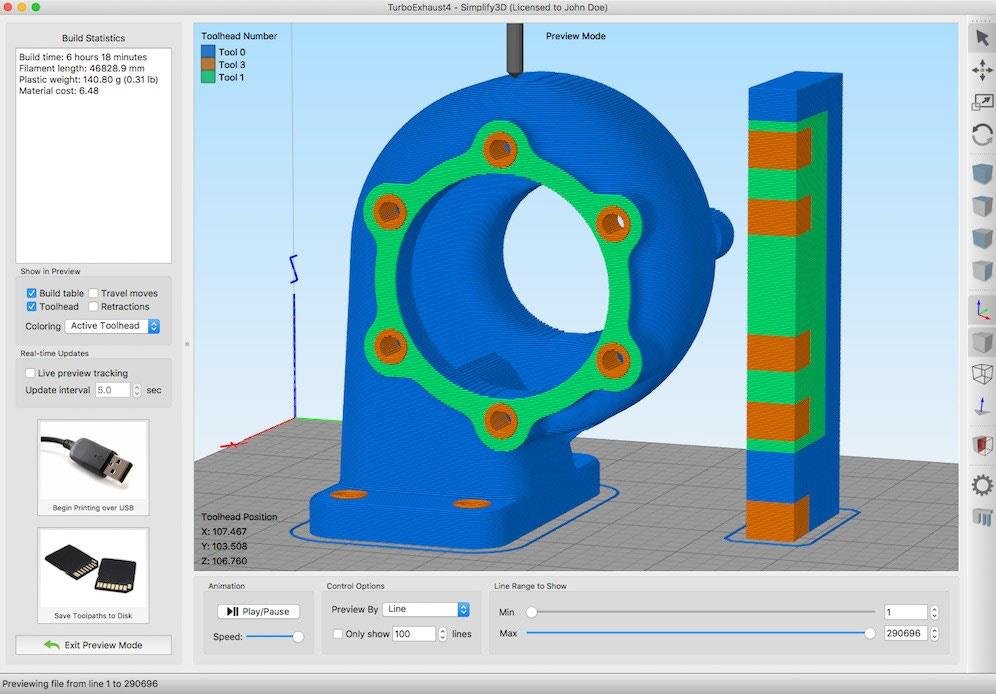

Learn how infill %, infill patterns and layer height impact the strength of a 3d print. This shape is the most efficient infill and fastest to print, the goto infill for most things. This is a custom design that i have made to test my slicer's infill/perimeter overlap. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Moroccan stars and catfill showed poorer performance in terms of while the tests conducted only covered a small range of the possible materials and machines used today in desktop 3d printing, it does offer a great. Infill percentage has an impact on strength when increasing this parameter it's set during the preparation of a part for printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). What is infill in 3d printing? Infill extrusion width does not make a difference here! This results in excess material on the outside of the model printed. Furthermore, hexagonal infills start to look very similar to linear past 30% infill. This because (i think) any roughness caused by an higher speed during the infill, is flattened when printing slowly the perimeter. Infill percentage in 3d printing. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. In addition to this tool, smith has also created what he calls a number of shells display, which is similar to the infill percentage display, but instead of showing various infill. It's a simple trick, and the prints come out nice! The first is to allow the user to specify the extrusion. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Editorial content, on principle, can not be bought or influenced. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. As of right now i can choose from a total of 7 different infill. The term 3d printing can refer to a variety of processes in which. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Printed parts can have high dimensional accurately however if simplify3d implemented three additional settings. Download files and build them with your 3d printer, laser cutter, or cnc. This video is a quick and easy method for reducing filament usage by reducing infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Thank you very much for allowing me to print and share it! Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with.

Printing With No Infill Ultimaker Cura Ultimaker Community Of 3d Printing Experts , Sometimes Parts Were Gotten Stronger With Minimal Infill But Good Wall Thickness Than Parts With.

Testing 3d Printed Infill Patterns For Their Strength Youtube. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. It's a simple trick, and the prints come out nice! Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). I noticed that dropping the infill can dramatically reduce plastic consumption. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. So what's the smallest % infill you have found you can get away with? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill the amount of material that occupies the internal part of the piece. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. This video is a quick and easy method for reducing filament usage by reducing infill. What is infill in 3d printing?

Wanted To See How Big I Could Print A Rex In Tpu With 1 Perimeter No Infill On A Cr10s Small One Is 100 Scale 3dprinting : Printing At Higher Infill Densities Will Of Course Make Your Object Stronger, But At The Cost Of More Materials, Longer Printing Times, And Reduced The Specific Infill Pattern You Use Will Have A Huge Effect On The Strength Of The Finished Part.

Cura Experimental Settings Adaptive Layers Spaghetti Infill And Molding Youtube. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill provides the 3d print with internal support as the printer builds each layer. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This video is a quick and easy method for reducing filament usage by reducing infill. It's a simple trick, and the prints come out nice! The infill the amount of material that occupies the internal part of the piece. I noticed that dropping the infill can dramatically reduce plastic consumption.

Cura Printing Without Shell Or Infill Only Ultimaker Cura Ultimaker Community Of 3d Printing Experts , Thingiverse is a universe of things.

Infill Failure When Printing Larger Prints 3d Printing Stack Exchange. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill provides the 3d print with internal support as the printer builds each layer. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. What is infill in 3d printing? So what's the smallest % infill you have found you can get away with? I noticed that dropping the infill can dramatically reduce plastic consumption. All3dp is an editorially independent publication. It's a simple trick, and the prints come out nice! This video is a quick and easy method for reducing filament usage by reducing infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Besides the actual printing process, infill will affect the strength or feel of the final product.

The Best Cura Infill Pattern For Your Needs All3dp - Triangular Infill Is The Strongest Infill Pattern Because Triangles Are The Strongest Shape.

Lithophane Print Settings Gadunky. Infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. So what's the smallest % infill you have found you can get away with? It's a simple trick, and the prints come out nice! What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). I noticed that dropping the infill can dramatically reduce plastic consumption. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This video is a quick and easy method for reducing filament usage by reducing infill. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of the piece.

What Is 3d Printer Infill And When Should It Be Used Home 3d Print Guide : You Can Also Select Any Cad Face (I.e.

Bulbasaur Printable With No Infill By Mike New Bulbasaur Pokemon Bulbasaur Printables. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. So what's the smallest % infill you have found you can get away with? Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. I noticed that dropping the infill can dramatically reduce plastic consumption. Infill percentage in 3d printing. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill provides the 3d print with internal support as the printer builds each layer. This video is a quick and easy method for reducing filament usage by reducing infill. All3dp is an editorially independent publication. It's a simple trick, and the prints come out nice! What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Infill Pattern Basics Simplify3d Youtube , Infill Provides The 3D Print With Internal Support As The Printer Builds Each Layer.

Iv Slicing As Lulzbot Says Slicing Software By Garrett Spiegel 3d Printing In O P Medium. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. It's a simple trick, and the prints come out nice! Infill provides the 3d print with internal support as the printer builds each layer. I noticed that dropping the infill can dramatically reduce plastic consumption. Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. Besides the actual printing process, infill will affect the strength or feel of the final product. This video is a quick and easy method for reducing filament usage by reducing infill. Infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). So what's the smallest % infill you have found you can get away with?

Pillowing Hestay . As Of Right Now I Can Choose From A Total Of 7 Different Infill.

A Parametric Study Of 3d Printed Polymer Gears Springerlink. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. So what's the smallest % infill you have found you can get away with? I noticed that dropping the infill can dramatically reduce plastic consumption. Infill provides the 3d print with internal support as the printer builds each layer. It's a simple trick, and the prints come out nice! This video is a quick and easy method for reducing filament usage by reducing infill.

3d Printing With No Infill Dont Waste Your Filament Youtube - What's The 3D Printing Problem?

My Prints Are Printing With No Infill Now When They Should Have 15 However I Don T Recall Changing Any Settings Are One Of These Settings Off 3dprinting. All3dp is an editorially independent publication. Besides the actual printing process, infill will affect the strength or feel of the final product. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. So what's the smallest % infill you have found you can get away with? I noticed that dropping the infill can dramatically reduce plastic consumption. This video is a quick and easy method for reducing filament usage by reducing infill. Editorial content, on principle, can not be bought or influenced. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). The infill the amount of material that occupies the internal part of the piece. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. It's a simple trick, and the prints come out nice! Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you.

Sanding Wedge By Xbost 3d Printing Projects 3d Printing 3d Printer . Once You Know What Your Print Is Going To Be Used For, You Should Have A General Idea Of The Pattern And Percentage That You.

Cura Experimental Settings Adaptive Layers Spaghetti Infill And Molding Youtube. This video is a quick and easy method for reducing filament usage by reducing infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. So what's the smallest % infill you have found you can get away with? It's a simple trick, and the prints come out nice! Infill provides the 3d print with internal support as the printer builds each layer. I noticed that dropping the infill can dramatically reduce plastic consumption. All3dp is an editorially independent publication. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced.

How To Choose An Infill For Your 3d Prints . Infill Is Added In The Middle Of The Print So That The Shell Of The Part Is Still Stiff When You Press On It.

3d Slicer Settings For Beginners 8 Things You Need To Know. All3dp is an editorially independent publication. I noticed that dropping the infill can dramatically reduce plastic consumption. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. It's a simple trick, and the prints come out nice! This video is a quick and easy method for reducing filament usage by reducing infill. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill percentage in 3d printing. So what's the smallest % infill you have found you can get away with? Infill provides the 3d print with internal support as the printer builds each layer.