3D Printing Nozzle Size Vs Layer Height. Layer height should not exceed 80 % of the nozzle diameter. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). If you use a very small nozzle and very low layer height, you'd need a very. Typically your maximum layer height is 80% of your nozzle size. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. 3d printing is not exactly a fast process. Even a print that is just a few inches tall can take several hours to complete. What is layer height in 3d printing? It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. It only takes a minute to sign up. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing.

3D Printing Nozzle Size Vs Layer Height , I'm Not Sure That The Threaded Rods Make Any Difference In What The Theoretical Maximum Layer Height Should Be For A Given Nozzle Diameter.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. Typically your maximum layer height is 80% of your nozzle size. If you use a very small nozzle and very low layer height, you'd need a very. What is layer height in 3d printing? 3d printing is not exactly a fast process. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Layer height should not exceed 80 % of the nozzle diameter. Even a print that is just a few inches tall can take several hours to complete. It only takes a minute to sign up. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print.

A shorter vertical layer results in a thicker horizontal line, and a taller vertical layer results in a thinner horizontal line.

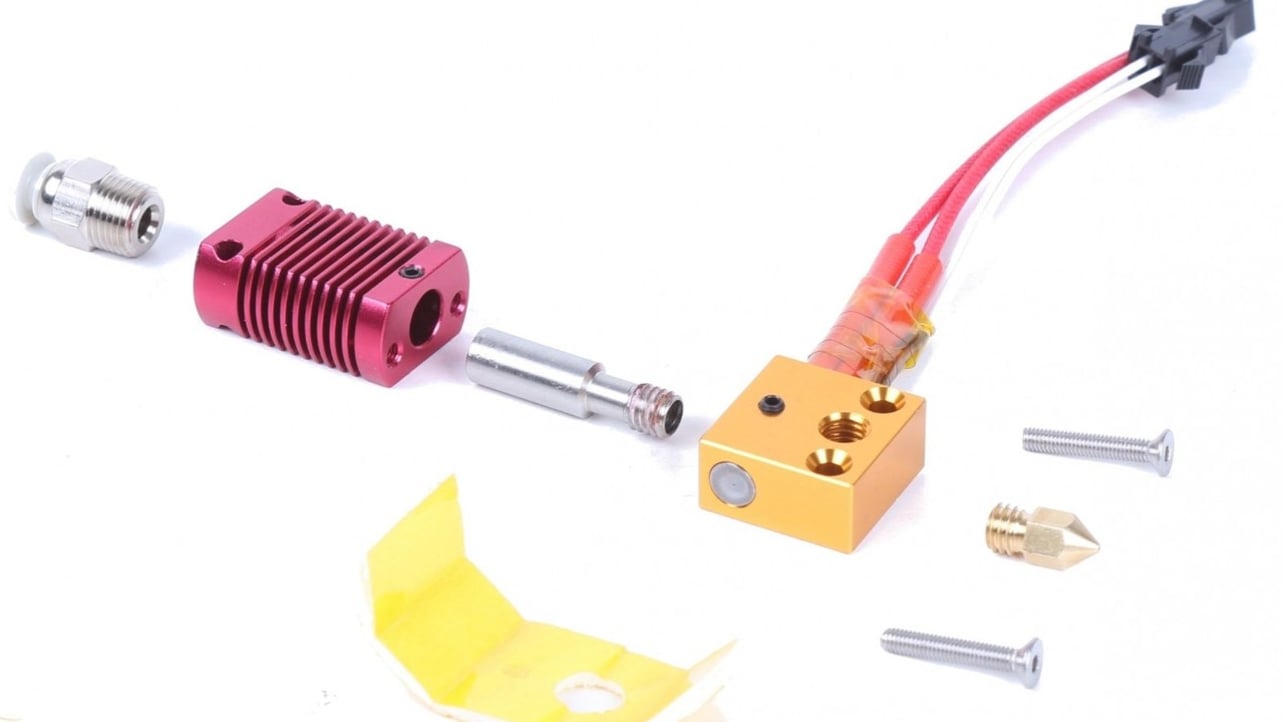

If you want higher resolution, then you would use smaller values. Typically your maximum layer height is 80% of your nozzle size. One size fits all settings. I made a model 20mm. Adaptive layer heights and nozzle sizes. The layer height of your 3d printed objects are important for quality, speed and even strength. The extruded filament may bulge outwards and upwards, especially when using a low layer height. If you want higher resolution, then you would use smaller values. This means that it will affect detailed features on the top surfaces of your prints. It only takes a minute to sign up. But why does it hold the height at the required layer height? It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. A 3d printer is going to have a difficult time printing any details smaller than the nozzle diameter. Classification of 3d printer nozzles. 0.2mm (photo at the bottom of the page). This little factor has a lot to do not only with print speed, but also detail. In the worth cas the plastic can expand/react/change state inside the hotend. So if you have a nozzle diameter of 0.4mm which is the standard nozzle size, you'll get a warning with a layer height anywhere from 0.32mm. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. Layer height should not exceed 80 % of the nozzle diameter. 3d printing layer height and its effect on part strenght and print speed. Yes, in order to change the layer thickness it is required to. If the first layer height is set greater than your layer height setting, the plastic is not being compressed at all. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. The heated nozzle portion of the extruder mechanism, which gets hot enough to melt plastic (or potentially polyvinyl alcohol is water soluble filament used as 3d printing material for support. A chain that is longer has a higher probability to fail earlier. 3d printing is not exactly a fast process. Extrusion multiplier, nozzle diameter, and filament diameter adjust print extrusion ratios. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament.

Everything About Nozzles With A Different Diameter Prusa Printers , Standard Configuration Numbers And Explanations.

Rarely Adjusted Slicer Setting Makes A Difference Hackaday. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. If you use a very small nozzle and very low layer height, you'd need a very. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. Layer height should not exceed 80 % of the nozzle diameter. Typically your maximum layer height is 80% of your nozzle size. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Even a print that is just a few inches tall can take several hours to complete. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. 3d printing is not exactly a fast process. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. It only takes a minute to sign up. What is layer height in 3d printing?

Help To Reconcile Nozzle Diameter Deposited Line Width And Wall Thickness In Cura 3d Printing Stack Exchange . Thermoplastics Extrude From This Tiny Hole In The Clogged Nozzles Happen Because Of Many Reasons Among Them Dust Particles Or Dirty Filament Forming A Plug, Nozzle Height Too Close To The Print.

Demystifying Thin Walls Matt S Hub. It only takes a minute to sign up. 3d printing is not exactly a fast process. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. What is layer height in 3d printing? If you use a very small nozzle and very low layer height, you'd need a very. Typically your maximum layer height is 80% of your nozzle size. Layer height should not exceed 80 % of the nozzle diameter. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc.

Fab Academy 2016 Steven Chew . Standard configuration numbers and explanations.

Which Layer Height Gives You The Strongest 3d Prints Youtube. Typically your maximum layer height is 80% of your nozzle size. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). What is layer height in 3d printing? Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. Layer height should not exceed 80 % of the nozzle diameter. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Even a print that is just a few inches tall can take several hours to complete. If you use a very small nozzle and very low layer height, you'd need a very. 3d printing is not exactly a fast process. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. It only takes a minute to sign up. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print.

How To 3d Print With A Larger Nozzle Matterhackers , In Slic3R, The Setting Is On The Print Settings Tab, In The Layers And Perimeters Section, And Is The Pictures Below Show Effect Of A Higher Vs Lower First Layer Height.

All About 3d Printer Nozzles I Classification And Recommendations. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Layer height should not exceed 80 % of the nozzle diameter. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. What is layer height in 3d printing? Typically your maximum layer height is 80% of your nozzle size. 3d printing is not exactly a fast process. Even a print that is just a few inches tall can take several hours to complete. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. If you use a very small nozzle and very low layer height, you'd need a very. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. It only takes a minute to sign up. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

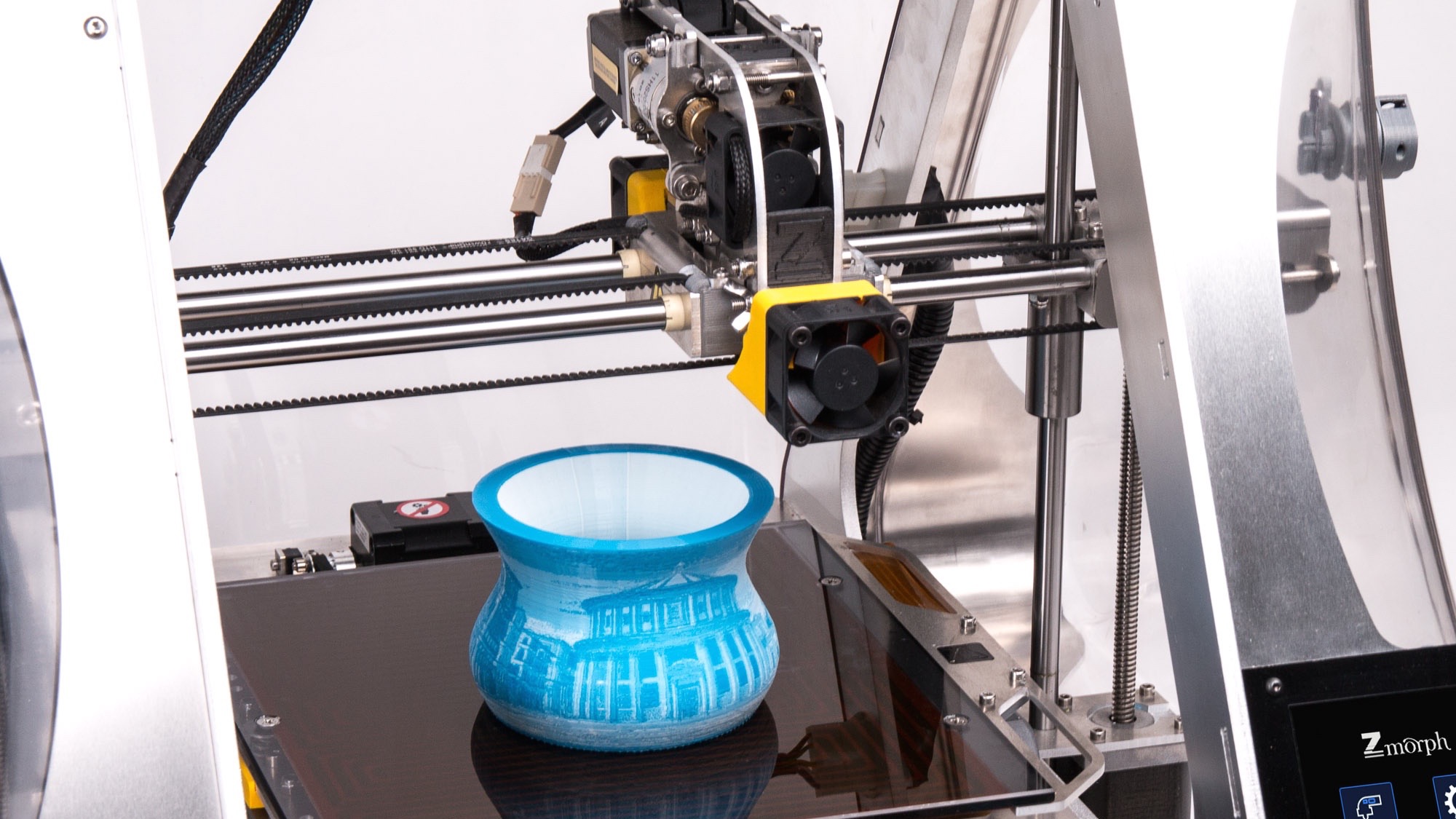

Rova3d A 3d Printer Based On Fdm Technology : A 3D Printer Is Going To Have A Difficult Time Printing Any Details Smaller Than The Nozzle Diameter.

What Resolution Can 3d Printers Print All3dp. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. Typically your maximum layer height is 80% of your nozzle size. It only takes a minute to sign up. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). 3d printing is not exactly a fast process. Layer height should not exceed 80 % of the nozzle diameter. Even a print that is just a few inches tall can take several hours to complete. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. What is layer height in 3d printing? If you use a very small nozzle and very low layer height, you'd need a very.

How To Design Parts For Fdm 3d Printing 3d Hubs . It's A Good Idea Figuring Out Which Layer Height Is The Best.

Everything About Nozzles With A Different Diameter Prusa Printers. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Typically your maximum layer height is 80% of your nozzle size. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. Even a print that is just a few inches tall can take several hours to complete. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Layer height should not exceed 80 % of the nozzle diameter. If you use a very small nozzle and very low layer height, you'd need a very. What is layer height in 3d printing? It only takes a minute to sign up. 3d printing is not exactly a fast process. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm).

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros . Due To The Additive Nature Of 3D Printing, The Thickness Of Each Layer Determines The Resolution Of A Print In A Similar Way That The.

My Testing With Layer Height And Extrusion Width 3dprinting. 3d printing is not exactly a fast process. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. It only takes a minute to sign up. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Layer height should not exceed 80 % of the nozzle diameter. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. If you use a very small nozzle and very low layer height, you'd need a very. Even a print that is just a few inches tall can take several hours to complete. Typically your maximum layer height is 80% of your nozzle size. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. What is layer height in 3d printing?

4 Things You Need To Know About 3d Printing Resolution , Extrusion Multiplier, Nozzle Diameter, And Filament Diameter Adjust Print Extrusion Ratios.

Can I Use A Smaller Nozzle For A High Resolution Model Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. Layer height should not exceed 80 % of the nozzle diameter. Even a print that is just a few inches tall can take several hours to complete. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. 3d printing is not exactly a fast process. Typically your maximum layer height is 80% of your nozzle size. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. What is layer height in 3d printing? In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). It only takes a minute to sign up. If you use a very small nozzle and very low layer height, you'd need a very. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

3d Printing For Dummies Pages 301 350 Flip Pdf Download Fliphtml5 - Usually I'm Running At 0.12 Layer Height For I Try To Keep The Prints Around 4 Hours So Sometimes I Go Thicker For Things That Don't Need The.

Can I Use A Smaller Nozzle For A High Resolution Model Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. 3d printing is not exactly a fast process. If you use a very small nozzle and very low layer height, you'd need a very. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. What is layer height in 3d printing? Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. Layer height should not exceed 80 % of the nozzle diameter. It only takes a minute to sign up. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Simply put, it's the thickness of each line of extruded material that makes up each layer of your print. Typically your maximum layer height is 80% of your nozzle size. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). Even a print that is just a few inches tall can take several hours to complete.

Everything About Nozzles With A Different Diameter Prusa Printers - The Layer Height Of Your 3D Printed Objects Are Important For Quality, Speed And Even Strength.

Nozzle Sizes Materials And Shapes For 3d Printers Fargo 3d Printing. 3d printing is not exactly a fast process. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Flow rate is the product of print speed, extrusion width (proportional to nozzle size) and print speed. Layer height should not exceed 80 % of the nozzle diameter. What is layer height in 3d printing? News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Even a print that is just a few inches tall can take several hours to complete. If you use a very small nozzle and very low layer height, you'd need a very. /r/3dprinting is a place where makers of all skill levels and walks of life can learn about and discuss 3d printing. Typically your maximum layer height is 80% of your nozzle size. It's best to experiment with the parameters of your print, as long as you understand the relationship between 3d printer nozzle size vs layer height you'll be on track. It only takes a minute to sign up. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Concerning print speed, yes the faster you go, the smaller (more stretched) the line but your slicer yes you can have any wall thickness but usually models designed for 3d printing will have wall thicknesses optimized for 0.4 nozzles (things like 2.4mm or 3.2 mm). Simply put, it's the thickness of each line of extruded material that makes up each layer of your print.