3D Printing Of Plastic Waste. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. Plastics are having a hugely negative effect on the environment; Small business development is the key to improving the lives of people in developing countries. 3d printing is a versatile process that simplifies existing. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. How can 3d printing change this? Our filament makers streamline innovation for engineers. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. I think that, as a whole, we can. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers.

3D Printing Of Plastic Waste - Plastics Are Having A Hugely Negative Effect On The Environment;

How The Automotive Industry Uses Recycled Plastic For 3d Printing Grabcad Blog. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. I think that, as a whole, we can. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. 3d printing is a versatile process that simplifies existing. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. How can 3d printing change this? Our filament makers streamline innovation for engineers. Small business development is the key to improving the lives of people in developing countries. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Plastics are having a hugely negative effect on the environment; Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer.

In this field, the technology of 3d printing enables closing the material loop of plastic with a short recycling path and a zero waste production process.

Uc berkeley students nicole panditi and scott silva have launched an initiative to create a campus wide system that collects and recycles plastic waste from 3d printers. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. The tools are open source. The city was able to create all kinds of original shapes and offer durable furniture, providing significant added value to the plastic waste. Extruder to create the 3d printer ink. Meanwhile, industrial machines can churn out objects as sophisticated as unmanned airplanes. Plastic has been accumulated on our earth since it was discovered and there is no way out to get rid of it, an alarming sign of pollution now. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. Plastics are having a hugely negative effect on the environment; The experience setup takes you trough the full experience of plastic recycling. To keep the public as informed as possible, each 3d printed piece of furniture installed in the city will be tagged with the kilos of plastic that it used. Then, once the plastic waste has been turned into filament, it will be returned to the same schools for use in educational 3d printing projects. As an industry built on plastic, fdm/fff 3d printing is also working to develop robust solutions to minimize refuse material. I think that, as a whole, we can. Our filament makers streamline innovation for engineers. Changing the way we deal with plastic waste, one 3d print at a time. Firstly, we collect plastic waste from fablabs, universities and companies. You will be able wear sunglasses made from the cup you just drank from. Usually, when someone makes a video about plastic waste, there's no peppy background music or happy messages. Festival goers will see live how we recycle and 3d print plastic waste into their own pair of sunglasses. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Plastic waste, in particular pet, which is typically found in soda bottles, is becoming abundant in african cities. At the same time, 3d printing is expanding 3d printing is an additive manufacturing process. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. 3d printing is a versatile process that simplifies existing. Collecting enough plastic waste and setting up a 3d printer to print the prosthetics was relatively easy. Dutch initiative precious plastics have created great tools to recycle waste plastic. They're printing every day, and that's a whole lot of waste that can only really end up in a landfill. Reflow turns plastic waste into 3d print filament, sends profits back to waste pickers. In this field, the technology of 3d printing enables closing the material loop of plastic with a short recycling path and a zero waste production process.

Guide To Green 3d Printing 4 Ways To Be More Sustainable , Reflow Turns Plastic Waste Into 3D Print Filament, Sends Profits Back To Waste Pickers.

Filamentive And Tridea Develop 100 Recycled 3d Printer Filament Made From Pet Plastic Bottles 3d Adept Media. 3d printing is a versatile process that simplifies existing. Our filament makers streamline innovation for engineers. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. Small business development is the key to improving the lives of people in developing countries. I think that, as a whole, we can. Plastics are having a hugely negative effect on the environment; Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. How can 3d printing change this? For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer.

Startup Converts Plastic Waste Into 3d Printing Material The Borgen Project . Startups Are Turning Plastic Waste In Developing Countries Into Filament For 3D Printers While Employing Local Waste Pickers.

Plastic Waste Bin For Filament Waste Of 3d Printers My3d Guru. How can 3d printing change this? Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. 3d printing is a versatile process that simplifies existing. Our filament makers streamline innovation for engineers. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Plastics are having a hugely negative effect on the environment; For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Small business development is the key to improving the lives of people in developing countries.

Print Your City 3d Printing Public Space With Plastic Waste 8 Materialdistrict - You will be able wear sunglasses made from the cup you just drank from.

New Project To Turn Waste Plastic Into 3d Printing Additives Resource Magazine. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Small business development is the key to improving the lives of people in developing countries. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. How can 3d printing change this? Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Our filament makers streamline innovation for engineers. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. 3d printing is a versatile process that simplifies existing. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastics are having a hugely negative effect on the environment; I think that, as a whole, we can.

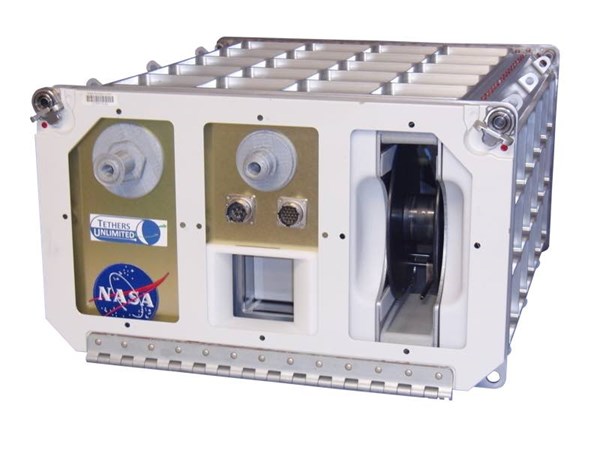

System To Recycle Waste Into 3d Printed Filament To Use In Space Plastics Technology - Plastic Has Been Accumulated On Our Earth Since It Was Discovered And There Is No Way Out To Get Rid Of It, An Alarming Sign Of Pollution Now.

3d Printer Filament Recycling Redetec. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. 3d printing is a versatile process that simplifies existing. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Small business development is the key to improving the lives of people in developing countries. Our filament makers streamline innovation for engineers. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. How can 3d printing change this? I think that, as a whole, we can. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastics are having a hugely negative effect on the environment; Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled.

3d Printing Sustainability Solving The Plastic Trash Crisis All3dp , Plastics Are Having A Hugely Negative Effect On The Environment;

Plastic Waste From 3d Printing Stock Image F022 0525 Science Photo Library. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastics are having a hugely negative effect on the environment; Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. Our filament makers streamline innovation for engineers. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. Small business development is the key to improving the lives of people in developing countries. I think that, as a whole, we can. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. How can 3d printing change this? Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. 3d printing is a versatile process that simplifies existing. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai.

From Recycled Plastic To 3d Printing More Creative Sustainable Fashion Solutions : The Tools Are Open Source.

3d Printing At The Heart Of Tanzanian Project To Reduce Plastic Waste And Save Lives Tct Magazine. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Our filament makers streamline innovation for engineers. 3d printing is a versatile process that simplifies existing. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. I think that, as a whole, we can. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Plastics are having a hugely negative effect on the environment; It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Small business development is the key to improving the lives of people in developing countries. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. How can 3d printing change this?

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcqml73brfvi Hplhmndnpii7bhznbtvc0ipqq Usqp Cau . You Will Be Able Wear Sunglasses Made From The Cup You Just Drank From.

3d Printing At The Beach Plastics. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. I think that, as a whole, we can. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. How can 3d printing change this? Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. Our filament makers streamline innovation for engineers. Small business development is the key to improving the lives of people in developing countries. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastics are having a hugely negative effect on the environment; For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. 3d printing is a versatile process that simplifies existing.

The Best 3d Printer To Recycle Your Plastic Zerowasteman The Best 3d Printer For Your Office : Usually, When Someone Makes A Video About Plastic Waste, There's No Peppy Background Music Or Happy Messages.

Microsoft Community Pitch Off Turning Plastic Waste Into Educational Supplies With 3d Printing 3dprint Com The Voice Of 3d Printing Additive Manufacturing. 3d printing is a versatile process that simplifies existing. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Plastics are having a hugely negative effect on the environment; Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. Our filament makers streamline innovation for engineers. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. How can 3d printing change this? This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Small business development is the key to improving the lives of people in developing countries. I think that, as a whole, we can.

3d Printed Furniture Out Of Recycled Plastic Waste Facfox - Firstly, We Collect Plastic Waste From Fablabs, Universities And Companies.

Plastic Waste Bin For Filament Waste Of 3d Printers My3d Guru. Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. Our filament makers streamline innovation for engineers. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. 3d printing is a versatile process that simplifies existing. Small business development is the key to improving the lives of people in developing countries. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Plastics are having a hugely negative effect on the environment; How can 3d printing change this? I think that, as a whole, we can. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai.

Plastic Waste From 3d Printing Stock Image F022 0525 Science Photo Library . Collecting Enough Plastic Waste And Setting Up A 3D Printer To Print The Prosthetics Was Relatively Easy.

Print Your City 3d Printing Public Space With Plastic Waste 8 Materialdistrict. This massive amount of plastic waste being collected via the ocean cleanup array and other endeavors provides a bountiful supply of resources the machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Plastic waste is a common problem in developing countries, and akabot could be used by social enterprise partners across the developing world. Making 3d printing ever more accessible, gigabot x by re:3d is a 3d printer that uses pellets of plastic waste to make 3d prints. The quality of the filament made from recycled waste plastic is a challenge for the whole 3d printing industry, says pai. For many, infill percentage is a held belief, same as political affiliation, religion, and camera brand manufacturer. Our products let you transform unneeded plastic (like ps and pet) and failed 3d prints into brand new filament. Plastics are having a hugely negative effect on the environment; It is estimated that more than 300 million tonnes of plastic are produced globally every year, with only 10% of that being recycled. How can 3d printing change this? Already at $60,310 with four days still to go, the re:3d gigabot x 3d printer has significantly surpassed its kickstarter goal of $50,000. I think that, as a whole, we can. Our filament makers streamline innovation for engineers. Startups are turning plastic waste in developing countries into filament for 3d printers while employing local waste pickers. 3d printing is a versatile process that simplifies existing. Small business development is the key to improving the lives of people in developing countries.