3D Printing On Textile. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. Tested parameters give us preliminary results about adhesion on textile fabric. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. In this instructable, i will show you how to print on three different kinds of fabric: One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. You can combine 3d printed designs with fabric to create exciting new textiles. It's a really interesting process that has a lot of possibilities still to be discovered. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Each year 1.600.000,00 kg of textile waste gets disposed. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. Therefor i 3d print to avoid textile waste!

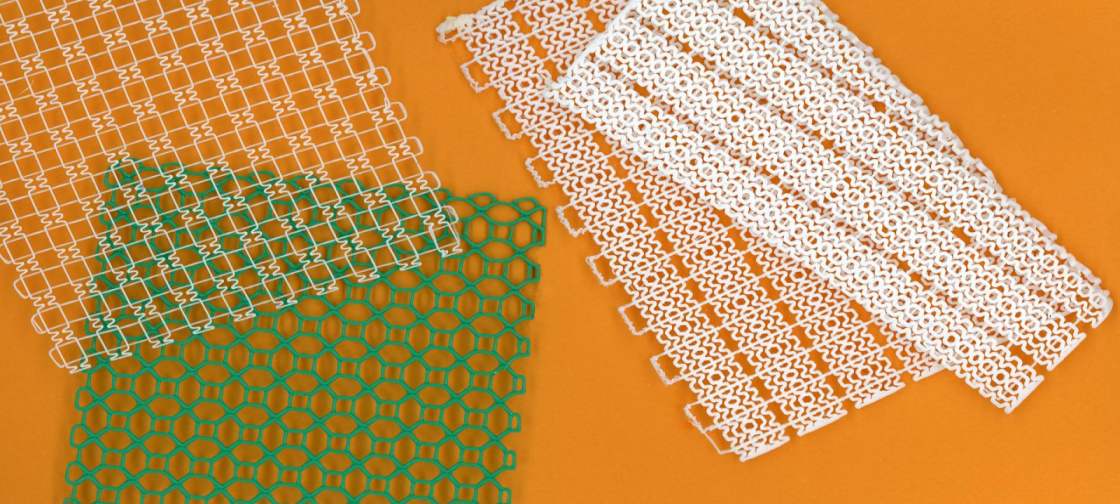

3D Printing On Textile . One Promising Avenue In This Field Is Combining 3D Printed Panels With The Traditional Textiles.

Can 3d Printing Pla Make A More Sustainable Textile Industry 3d Printing Industry. It's a really interesting process that has a lot of possibilities still to be discovered. Therefor i 3d print to avoid textile waste! Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. In this instructable, i will show you how to print on three different kinds of fabric: Each year 1.600.000,00 kg of textile waste gets disposed. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Tested parameters give us preliminary results about adhesion on textile fabric. You can combine 3d printed designs with fabric to create exciting new textiles.

Pointcarre textile software provides weaving cad and surface solutions for fashion, home furnishing and wall covering designers.

Digital textile printing and why preflighting is important. 021 525 62 03 fast respon, please contact phone number. You can combine 3d printed designs with fabric to create exciting new textiles. An original print is a simple way to turn a garment into a design piece. Seamless illustration with dream catchers. Tamicare has spent the past decade developing and patenting a unique system to get 3d textile printing ready for mass production. Seamless animal skin fabric textile pattern. 544 x 544 jpeg 37 кб. +62878 8080 57 37 ☎ : Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Therefor i 3d print to avoid textile waste! Pointcarre program helps you from the design creation, the fabric simulation to the final manufacturing process. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. You'll never need to look for a 3d printing service again! The term 3d printing can refer to a variety of processes in which. The line is capable of producing up to three million items annually while virtually eliminating waste. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. Pointcarre textile software provides weaving cad and surface solutions for fashion, home furnishing and wall covering designers. 3d printers to transform your practice — envisiontec is the leading choice for orthodontic applications. This is a 3d printable, flexible fashion textile that looks great. With the arrival of advanced techniques such as textile sublimation, the possibilities have multiplied to the point where it is possible to create your. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. Digital textile printing and why preflighting is important. Fabric printing refers to creating beautiful designs and patterns on textile surfaces. Look at our awesome garment decoration & textile printing solutions equipments. In the production process of textiles, the printing of patterns and designs comes somewhat in the final stages. This is the perfect tutorial. Popular mini 3d digital textile printing flatbed printer. Tested parameters give us preliminary results about adhesion on textile fabric.

3d Print Fabtextiles , The Model Shown Is Printed From Pla, So It Is A Strong And Lightweight Material That Is Connected Together To Create A Sheet Of Textile.

Shapemode S 3d Printed Textiles Win Special Adi Award In Expo Dubai 2020 Design Competition Texintel. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. In this instructable, i will show you how to print on three different kinds of fabric: It's a really interesting process that has a lot of possibilities still to be discovered. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. Each year 1.600.000,00 kg of textile waste gets disposed. Tested parameters give us preliminary results about adhesion on textile fabric. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. You can combine 3d printed designs with fabric to create exciting new textiles. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Therefor i 3d print to avoid textile waste! One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes.

Textile Spotlight 3d Printed Fabric - 3D Printing In The Textile Industry Lets You Unleash Your Imagination In Order To Quickly Create New Structures Through Innovative New Materials.

3d Printed Fabrics Tessa S Weekly Picks Leo Lane. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. Therefor i 3d print to avoid textile waste! 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. You can combine 3d printed designs with fabric to create exciting new textiles. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. Tested parameters give us preliminary results about adhesion on textile fabric. In this instructable, i will show you how to print on three different kinds of fabric: Each year 1.600.000,00 kg of textile waste gets disposed.

3d Printing The Future Of Retail : Print logistic is the number one innovator in textile and direct to garment (dtg) printing in poland.

Meg Grant 3d Printed Textile Origami. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. In this instructable, i will show you how to print on three different kinds of fabric: You can combine 3d printed designs with fabric to create exciting new textiles. Therefor i 3d print to avoid textile waste! Each year 1.600.000,00 kg of textile waste gets disposed. Tested parameters give us preliminary results about adhesion on textile fabric. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. It's a really interesting process that has a lot of possibilities still to be discovered.

Textile Spotlight 3d Printed Fabric - Belgian Design Studio Unfold's Personal Fabrication Blog, Where We Detail The Progress Of Various Projects.

English Researchers Use 3d Printing To Produce Flexible And Fine Textile Like Structures 3d Printed Fabric 3d Printing Fashion 3d Printing. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. It's a really interesting process that has a lot of possibilities still to be discovered. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. You can combine 3d printed designs with fabric to create exciting new textiles. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Tested parameters give us preliminary results about adhesion on textile fabric. Each year 1.600.000,00 kg of textile waste gets disposed. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Therefor i 3d print to avoid textile waste! In this instructable, i will show you how to print on three different kinds of fabric: Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes.

3d Textiles Embracing The Depth Textile World , Tested Parameters Give Us Preliminary Results About Adhesion On Textile Fabric.

Digital Interlooping How 3d Printing And Textiles Are Becoming Closely Knit 3d Printing Media Network The Pulse Of The Am Industry. Therefor i 3d print to avoid textile waste! See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. You can combine 3d printed designs with fabric to create exciting new textiles. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. In this instructable, i will show you how to print on three different kinds of fabric: Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. It's a really interesting process that has a lot of possibilities still to be discovered. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Each year 1.600.000,00 kg of textile waste gets disposed. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. Tested parameters give us preliminary results about adhesion on textile fabric. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials.

Digital Interlooping How 3d Printing And Textiles Are Becoming Closely Knit 3d Printing Media Network The Pulse Of The Am Industry , Each Year 1.600.000,00 Kg Of Textile Waste Gets Disposed.

3d Printed Fabric The Most Promising Projects All3dp. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Each year 1.600.000,00 kg of textile waste gets disposed. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. In this instructable, i will show you how to print on three different kinds of fabric: See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. It's a really interesting process that has a lot of possibilities still to be discovered. Tested parameters give us preliminary results about adhesion on textile fabric. Therefor i 3d print to avoid textile waste! You can combine 3d printed designs with fabric to create exciting new textiles. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university.

3d Printed Fabric The Most Promising Projects All3dp - This Is The Perfect Tutorial.

3d Printing And Fashion Clothing 3d Printed Garments Apparel. It's a really interesting process that has a lot of possibilities still to be discovered. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. You can combine 3d printed designs with fabric to create exciting new textiles. Therefor i 3d print to avoid textile waste! Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. Tested parameters give us preliminary results about adhesion on textile fabric. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Each year 1.600.000,00 kg of textile waste gets disposed. In this instructable, i will show you how to print on three different kinds of fabric:

Costume Designer Creates Textile Print Block With Shopbot Shopbot Blog : An Original Print Is A Simple Way To Turn A Garment Into A Design Piece.

3d Printing In Textile Industry Clothes And Textile. In this instructable, i will show you how to print on three different kinds of fabric: 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. You can combine 3d printed designs with fabric to create exciting new textiles. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. Therefor i 3d print to avoid textile waste! It's a really interesting process that has a lot of possibilities still to be discovered. Each year 1.600.000,00 kg of textile waste gets disposed. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. Tested parameters give us preliminary results about adhesion on textile fabric. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create.

Direct To Textile 3d Printing Stratasys - Seamless Animal Skin Fabric Textile Pattern.

3d Printing In Textile Industry Clothes And Textile. Therefor i 3d print to avoid textile waste! Each year 1.600.000,00 kg of textile waste gets disposed. It's a really interesting process that has a lot of possibilities still to be discovered. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. Tested parameters give us preliminary results about adhesion on textile fabric. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented. You can combine 3d printed designs with fabric to create exciting new textiles. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. In this instructable, i will show you how to print on three different kinds of fabric: See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects.

3d Printing In Textile Industry Clothes And Textile , Последние Твиты От 3D Printing Industry (@3Dprintindustry).

Triangulated 3d Printed Textile Youtube. Therefor i 3d print to avoid textile waste! See more ideas about 3d printing fashion, 3d fashion, 3d print, print, print. For textile companies, 3d printing processes open up possibilities that cannot be realized with conventional processes. The possibilities of 3d printing in the textiles industry are boundless, and although we are yet at the stage where garments can be fully 3d printed in the home, with the help of frances murphy positive steps are being made towards a revolutionised, circular fashion and textiles industry, said create. Tested parameters give us preliminary results about adhesion on textile fabric. You can combine 3d printed designs with fabric to create exciting new textiles. It's a really interesting process that has a lot of possibilities still to be discovered. Belgian design studio unfold's personal fabrication blog, where we detail the progress of various projects. Each year 1.600.000,00 kg of textile waste gets disposed. Another interesting 4d printing process for the textile industry has been developed by scientists at the wyss institute at harvard university. In this instructable, i will show you how to print on three different kinds of fabric: 3d printing in the textile industry lets you unleash your imagination in order to quickly create new structures through innovative new materials. One of these two materials associated with the conventional textile will allow you to create innovative clothing and perfectly suited to your body type. 3d printed geometries on textile fabrics are a new possibility for fashion designers to individualize. Interactions between 3d printed objects and textile fabrics in terms of adhesion and sustainability after washing are presented.