3D Printing Plastic Powder. A complete solution for polymer powders for laser sintering. You can also choose from manufacturing. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. That's because dense powder surrounds the 3d print until its finished. 0:15 metalysis 17 056 просмотров. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. A wide variety of 3d printing plastic powder options are available to you, such as new. 1:32 cooper hewitt 57 167 просмотров. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. A huge advantage of sls is that overhangs and floating objects don't need support structures. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. 2020 promises to be the year of polymer 3d printing. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or.

3D Printing Plastic Powder : 2020 Promises To Be The Year Of Polymer 3D Printing.

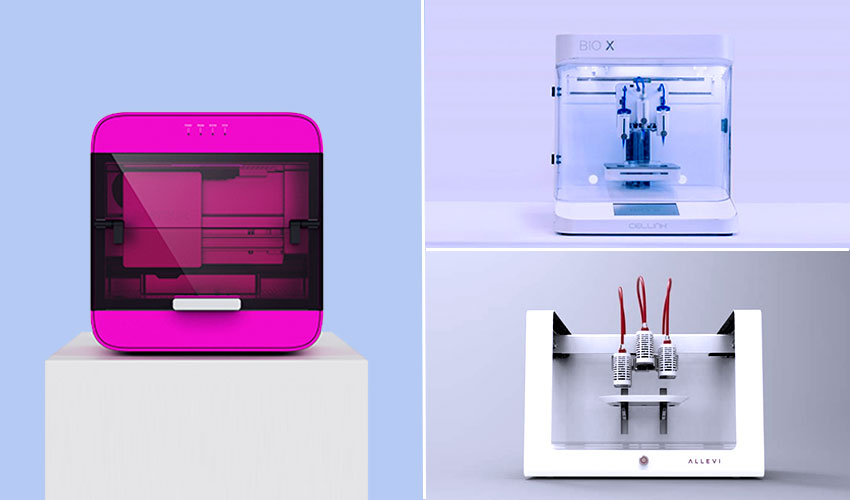

The Different Sls 3d Printers On The Market 3dnatives. You can also choose from manufacturing. 0:15 metalysis 17 056 просмотров. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 2020 promises to be the year of polymer 3d printing. A huge advantage of sls is that overhangs and floating objects don't need support structures. A wide variety of 3d printing plastic powder options are available to you, such as new. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. 1:32 cooper hewitt 57 167 просмотров. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. A complete solution for polymer powders for laser sintering. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. That's because dense powder surrounds the 3d print until its finished.

In powder form, materials like steel, copper and other types of metal are easier to transport and mold into desired shapes.

Plastic is the most common material for such printing. We produce hundreds of thousands of plastic parts with our printers. To produce the piece, the printer builds the model using a head that moves over the platform base and deposits, one layer at a time, by spreading a layer of powder (plaster, or resins). You could easily put rocks on top of each other to build a pyramid. Choose from plastic and metal 3d printing for extremely accurate prototypes and fully functional production parts in as fast as 1 day. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. Plastic is the most common material for such printing. Direct metal laser sintering (dmls) uses a fiber laser system that draws onto a surface of atomized metal powder, welding the powder into fully dense metal parts. A complete solution for polymer powders for laser sintering. 1:32 cooper hewitt 57 167 просмотров. Inside the printer, the powder is melted and distributed in layers until the desired thickness, texture and patterns are made. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. Shapeways, another manufacturer, discontinued its ceramics. A wide variety of 3d printing plastic powder options are available to you, such as new. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. That's because dense powder surrounds the 3d print until its finished. With many metals having a melting point greater than 500° c or 1,000° f, metal 3d printers are expensive and potentially sculpteo, a 3d printing service bureau, prints in ceramic with a z corp 3d printer. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. As with the various types of plastic used in 3d printing. You can also choose from manufacturing. In powder form, materials like steel, copper and other types of metal are easier to transport and mold into desired shapes. At sculpteo, we use the most common variety of polyamide, which is pa 2200 or pa12, but there are many other variants of polyamide plastic such as polyamide 11(or nylon 11, pa 11 and french nylon), polyamide 6. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. Versatile plastic is a porous material and the dye can penetrate the surface up to 0.5 mm. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. In case that the surface is broken or scratched, then the original white color will be displayed. This method is also known as inkjet 3d printing system. Unlike with most home printers, polyamide prints are not created using a plastic filament. A huge advantage of sls is that overhangs and floating objects don't need support structures. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes.

Introduction To Binder Jetting 3d Printing 3d Hubs - In Powder Form, Materials Like Steel, Copper And Other Types Of Metal Are Easier To Transport And Mold Into Desired Shapes.

Post Processing Of Plastic Parts From The 3d Printer Eos. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 1:32 cooper hewitt 57 167 просмотров. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. A huge advantage of sls is that overhangs and floating objects don't need support structures. 2020 promises to be the year of polymer 3d printing. That's because dense powder surrounds the 3d print until its finished. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. A complete solution for polymer powders for laser sintering. You can also choose from manufacturing. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 0:15 metalysis 17 056 просмотров. A wide variety of 3d printing plastic powder options are available to you, such as new.

3d Printing Plastics Market Size Share Industry Report 2025 - 873 3D Printing Plastic Powder Products Are Offered For Sale By Suppliers On Alibaba.cOm, Of Which Other Plastic Raw Materials Accounts For 1%, Pigment Accounts For 1%.

What Is Sls 3d Printing Sinterit Manufacturer Of High Quality Desktop Sls 3d Printers. 1:32 cooper hewitt 57 167 просмотров. That's because dense powder surrounds the 3d print until its finished. A huge advantage of sls is that overhangs and floating objects don't need support structures. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. 0:15 metalysis 17 056 просмотров. A wide variety of 3d printing plastic powder options are available to you, such as new. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. A complete solution for polymer powders for laser sintering.

3d Printing Service Sculpteo Introduces Solid Black Plastic 3printr Com , As with the various types of plastic used in 3d printing.

3d Printing Powder Stanford Advanced Materials. You can also choose from manufacturing. 1:32 cooper hewitt 57 167 просмотров. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. That's because dense powder surrounds the 3d print until its finished. 0:15 metalysis 17 056 просмотров. A huge advantage of sls is that overhangs and floating objects don't need support structures. A complete solution for polymer powders for laser sintering. A wide variety of 3d printing plastic powder options are available to you, such as new. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. 2020 promises to be the year of polymer 3d printing. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%.

3d Metal Printing How Does It Work : This Method Is Also Known As Inkjet 3D Printing System.

Plastics That Can Be Recycled For 3d Printing Perpetual Plastic Project. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. You can also choose from manufacturing. That's because dense powder surrounds the 3d print until its finished. A wide variety of 3d printing plastic powder options are available to you, such as new. 1:32 cooper hewitt 57 167 просмотров. A complete solution for polymer powders for laser sintering. A huge advantage of sls is that overhangs and floating objects don't need support structures. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 2020 promises to be the year of polymer 3d printing. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 0:15 metalysis 17 056 просмотров.

3d Metal Printing How Does A 3d Metal Printer Work Spi : You Can Also Choose From Manufacturing.

Polymer Powders Prodways. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. A complete solution for polymer powders for laser sintering. You can also choose from manufacturing. A wide variety of 3d printing plastic powder options are available to you, such as new. That's because dense powder surrounds the 3d print until its finished. 1:32 cooper hewitt 57 167 просмотров. 0:15 metalysis 17 056 просмотров. A huge advantage of sls is that overhangs and floating objects don't need support structures. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. 2020 promises to be the year of polymer 3d printing. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath.

Powdered Metals And 3d Printing Creating Components For Aerospace Automotive And Medical Industries . Unlike With Most Home Printers, Polyamide Prints Are Not Created Using A Plastic Filament.

What Is Powder Based 3d Printing 3d Insider. You can also choose from manufacturing. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. 2020 promises to be the year of polymer 3d printing. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. 0:15 metalysis 17 056 просмотров. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. A complete solution for polymer powders for laser sintering. A huge advantage of sls is that overhangs and floating objects don't need support structures. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. A wide variety of 3d printing plastic powder options are available to you, such as new. That's because dense powder surrounds the 3d print until its finished. 1:32 cooper hewitt 57 167 просмотров. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser.

Selective Laser Sintering Sls Cyant . Shapeways, Another Manufacturer, Discontinued Its Ceramics.

3d Printing Powder Market By Type Metal Plastic Ceramic By End. You can also choose from manufacturing. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. A huge advantage of sls is that overhangs and floating objects don't need support structures. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. 1:32 cooper hewitt 57 167 просмотров. A complete solution for polymer powders for laser sintering. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. That's because dense powder surrounds the 3d print until its finished. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. A wide variety of 3d printing plastic powder options are available to you, such as new. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. 2020 promises to be the year of polymer 3d printing. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. 0:15 metalysis 17 056 просмотров.

Abs Plastic Material For 3d Printing Fdm Thermoplastic Material - This Makes It Possible To 3D Print Moving Parts, Overhangs, Underhangs And Cavities Without The Need For A Separate Support Material To Be Washed Away Or.

What Materials Are Used For 3d Printing Sharretts Plating Company. 2020 promises to be the year of polymer 3d printing. You can also choose from manufacturing. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. That's because dense powder surrounds the 3d print until its finished. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 1:32 cooper hewitt 57 167 просмотров. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. A wide variety of 3d printing plastic powder options are available to you, such as new. 0:15 metalysis 17 056 просмотров. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. A complete solution for polymer powders for laser sintering. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. A huge advantage of sls is that overhangs and floating objects don't need support structures.

Farsoon Cams 3d Printer Will Be The Largest Plastic Powder Bed System 3d Printing Industry , You Can Also Choose From Manufacturing.

3d Printing Materials Market Global Forecast To 2025 Marketsandmarkets. A wide variety of 3d printing plastic powder options are available to you, such as new. You can also choose from manufacturing. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. 1:32 cooper hewitt 57 167 просмотров. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible. A complete solution for polymer powders for laser sintering. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. A huge advantage of sls is that overhangs and floating objects don't need support structures. 2020 promises to be the year of polymer 3d printing. That's because dense powder surrounds the 3d print until its finished. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. 0:15 metalysis 17 056 просмотров.

Multi Material 3d And 4d Printing A Survey Rafiee 2020 Advanced Science Wiley Online Library - Choose From Plastic And Metal 3D Printing For Extremely Accurate Prototypes And Fully Functional Production Parts In As Fast As 1 Day.

China Polyamide 3d Printing Nylon Plastic Powder Material For Sls China Materials Used In 3d Printing Powder 3d Printer. This makes it possible to 3d print moving parts, overhangs, underhangs and cavities without the need for a separate support material to be washed away or. 1:32 cooper hewitt 57 167 просмотров. You can also choose from manufacturing. As major chemical companies are now joining the 3d printing world and industry mainstays are further selective laser sintering (sls) is an additive manufacturing process that involves the fusing of plastic powdered material using a powerful laser. 0:15 metalysis 17 056 просмотров. A huge advantage of sls is that overhangs and floating objects don't need support structures. 873 3d printing plastic powder products are offered for sale by suppliers on alibaba.com, of which other plastic raw materials accounts for 1%, pigment accounts for 1%. That's because dense powder surrounds the 3d print until its finished. 2020 promises to be the year of polymer 3d printing. Plastics are 3d printed like printing with a inkjet printing head which places small particles of light curing plastic on a print bed. Nylon 12 is a white powder, so all versatile plastic models are printed white and then dyed in a hot color bath. Plastic powder bed processes have a unique benefit in that the powder itself can act as a support material for subsequent layers. A wide variety of 3d printing plastic powder options are available to you, such as new. A complete solution for polymer powders for laser sintering. The unique technology of the promaker p series laser sintering printers opens up new ways for prodways to develop materials with mechanical properties that have been inaccessible.