3D Printing Plastic Properties. Select a plastic material and 3d explore the best printers in the industry. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. This 3d plastic printing technology is great for spare parts, prototypes and functional components. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. Resulting parts have a high surface quality and properties range from elastic to stiff. 3d systems invented 3d printing. Plastics and metals are two most popular 3d printing material. We produce hundreds of thousands of plastic parts with our printers. These properties make abs very suitable for 3d printing. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. At this point, the melted filament is homogenously the properties of biofila are amazing. Desc commodity plastic, improved mechanical and thermal properties compared to pla.

3D Printing Plastic Properties . In Addition To Its Chemical Resistance And Mechanical Properties, Abs Material Has A Good Surface Quality And Is Flame Retardant.

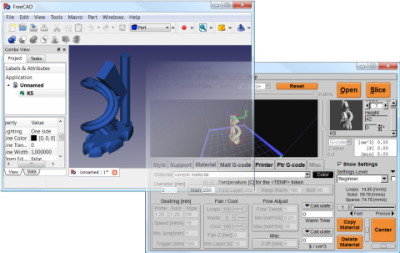

3d Printing Materials Properties And Material Simulation. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. Desc commodity plastic, improved mechanical and thermal properties compared to pla. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. 3d systems invented 3d printing. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. Select a plastic material and 3d explore the best printers in the industry. We produce hundreds of thousands of plastic parts with our printers. Resulting parts have a high surface quality and properties range from elastic to stiff. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. At this point, the melted filament is homogenously the properties of biofila are amazing. Plastics and metals are two most popular 3d printing material. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. These properties make abs very suitable for 3d printing. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. This 3d plastic printing technology is great for spare parts, prototypes and functional components.

Most engineers and designers choose metals to.

We offer a wide range of 3d printing materials with fdm, sls, sla, polyjet and dmls technology. This 3d plastic printing technology is great for spare parts, prototypes and functional components. Check out the metal powder used in the craft below. We produce hundreds of thousands of plastic parts with our printers. It can fabricate parts with multiple properties such as colors and materials. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending on other. In what ways is drilling a hole in a model made from that material like or unlike drilling wood? Standard test method for tensile properties of plastics. Discover abs plastic commonly used in 3d printing. While most plastic filaments, like abs and pla, are excellent for printing numerous solid shapes and objects, that are also some other materials that after an initial rinising in tap water, similar viscoelastic properties can be achieved by soaking it in oil and alcohol mixtures, in a low concentration of glycerol. * fine detail plastic is printed on a build plate, where the print head deposits liquid plastic layer by layer, starting at the bottom. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. These properties make abs very suitable for 3d printing. Since 3d printing doesn't require. (2017) experimental characterization of the mechanical properties of 3d printed abs and polycarbonate parts. The biggest range of quality 3d printer plastic in australia. Designers can leverage the technology for prototyping elastomeric or overmolded parts. Desc commodity plastic, improved mechanical and thermal properties compared to pla. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. Here is a blog post about the differences between plastic 3d printing and metal 3d 3d printing with metals offers an unique combination of practical and aesthetic properties. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. For each material, we've listed the properties, applications and their corresponding. Before 3d printing with pla make sure your 3d printer meets the hardware requirements listed below to cooling is one of the most important aspects of printing with pla. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. At this point, the melted filament is homogenously the properties of biofila are amazing. Nylon 618 is common for 3d printing: These properties make abs very suitable for 3d printing. Most engineers and designers choose metals to.

Fea For 3d Printing Finite Element Analysis For 3d Printing 3d Matter - It Can Fabricate Parts With Multiple Properties Such As Colors And Materials.

3d Printing With Petg Tips And Tricks Airwolf 3d Printers. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. This 3d plastic printing technology is great for spare parts, prototypes and functional components. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. These properties make abs very suitable for 3d printing. Select a plastic material and 3d explore the best printers in the industry. Resulting parts have a high surface quality and properties range from elastic to stiff. We produce hundreds of thousands of plastic parts with our printers. 3d systems invented 3d printing. Plastics and metals are two most popular 3d printing material. Desc commodity plastic, improved mechanical and thermal properties compared to pla. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. At this point, the melted filament is homogenously the properties of biofila are amazing. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse.

Why Dubai Wants To Be A 3d Printed City Cnn Style : Polyjet Is Another Plastic 3D Printing Process, But There's A Twist.

Petg Vs Abs Vs Asa. Select a plastic material and 3d explore the best printers in the industry. At this point, the melted filament is homogenously the properties of biofila are amazing. We produce hundreds of thousands of plastic parts with our printers. These properties make abs very suitable for 3d printing. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. 3d systems invented 3d printing. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. This 3d plastic printing technology is great for spare parts, prototypes and functional components. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model.

Advanced Guide To Printing Petg Filament Latest 3d Printer News Article 3d Printing Solutions - * fine detail plastic is printed on a build plate, where the print head deposits liquid plastic layer by layer, starting at the bottom.

What Material Should I Use For 3d Printing 3d Printing For Beginners. 3d systems invented 3d printing. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. Select a plastic material and 3d explore the best printers in the industry. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. Plastics and metals are two most popular 3d printing material. At this point, the melted filament is homogenously the properties of biofila are amazing. This 3d plastic printing technology is great for spare parts, prototypes and functional components. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. Resulting parts have a high surface quality and properties range from elastic to stiff. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. We produce hundreds of thousands of plastic parts with our printers. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. Desc commodity plastic, improved mechanical and thermal properties compared to pla. These properties make abs very suitable for 3d printing.

Carbon Fiber Filament Strength Properties Tips For 3d Printing 2020 : Plastics Are Generally Low Cost, Easy To Manufacture, Durable, Strong For Their Weight, Electrically And Thermally Insulative, And Resistant 3D Printing (Aka Rapid Prototyping) Is An Additive Manufacturing Process.

Microwave Electronic Circuits Made Via Low Cost 3d Printer Plastic Filament 3dprintmoney Com. Desc commodity plastic, improved mechanical and thermal properties compared to pla. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. Resulting parts have a high surface quality and properties range from elastic to stiff. At this point, the melted filament is homogenously the properties of biofila are amazing. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. This 3d plastic printing technology is great for spare parts, prototypes and functional components. Plastics and metals are two most popular 3d printing material. 3d systems invented 3d printing. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. These properties make abs very suitable for 3d printing. Select a plastic material and 3d explore the best printers in the industry. We produce hundreds of thousands of plastic parts with our printers. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model.

3d Printing Plastics Market Size Industry Report 2018 2025 , Since 3D Printing Doesn't Require.

An Introduction To 3d Printing With Plastics Amfg. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. Select a plastic material and 3d explore the best printers in the industry. These properties make abs very suitable for 3d printing. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. Plastics and metals are two most popular 3d printing material. We produce hundreds of thousands of plastic parts with our printers. This 3d plastic printing technology is great for spare parts, prototypes and functional components. Resulting parts have a high surface quality and properties range from elastic to stiff. Desc commodity plastic, improved mechanical and thermal properties compared to pla. At this point, the melted filament is homogenously the properties of biofila are amazing. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. 3d systems invented 3d printing.

An Introduction To 3d Printing With Plastics Amfg : Desc Commodity Plastic, Improved Mechanical And Thermal Properties Compared To Pla.

Pdf About The Use Of Recycled Or Biodegradable Filaments For Sustainability Of 3d Printing. 3d systems invented 3d printing. Desc commodity plastic, improved mechanical and thermal properties compared to pla. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. At this point, the melted filament is homogenously the properties of biofila are amazing. We produce hundreds of thousands of plastic parts with our printers. This 3d plastic printing technology is great for spare parts, prototypes and functional components. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. These properties make abs very suitable for 3d printing. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. Select a plastic material and 3d explore the best printers in the industry. Plastics and metals are two most popular 3d printing material. Resulting parts have a high surface quality and properties range from elastic to stiff.

Ultimate Materials Guide Tips For 3d Printing With Pla , Polylactic Acid (Pla) Is A Polymer Plastic, Made From Biological Materials Like Cornstarch Or Sugarcane.

3d Printer Companies Build Face Shields Masks More To Fight Coronavirus Cnet. Plastics and metals are two most popular 3d printing material. This 3d plastic printing technology is great for spare parts, prototypes and functional components. 3d systems invented 3d printing. Resulting parts have a high surface quality and properties range from elastic to stiff. At this point, the melted filament is homogenously the properties of biofila are amazing. Select a plastic material and 3d explore the best printers in the industry. Desc commodity plastic, improved mechanical and thermal properties compared to pla. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. We produce hundreds of thousands of plastic parts with our printers. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. These properties make abs very suitable for 3d printing. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane.

What Is The Strongest 3d Printer Filament Airwolf 3d . Is It Worth Getting Special Plastic Drilling Bits That Cost Tons Of Money Or Can I Use Regular High Speed Drill Bits?

3d Printing With Petg Tips And Tricks Airwolf 3d Printers. At this point, the melted filament is homogenously the properties of biofila are amazing. Plastics and metals are two most popular 3d printing material. Select a plastic material and 3d explore the best printers in the industry. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. We produce hundreds of thousands of plastic parts with our printers. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. 3d systems invented 3d printing. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. These properties make abs very suitable for 3d printing. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. Resulting parts have a high surface quality and properties range from elastic to stiff. This 3d plastic printing technology is great for spare parts, prototypes and functional components. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. Desc commodity plastic, improved mechanical and thermal properties compared to pla.

3d Printing Materials Properties And Material Simulation , It Is Similar To The Material Used In Biodegradable Plastic Packaging And Melts At Between 180 And 200 Degrees C, Depending.

How To Improve Your 3d Prints With Annealing Prusa Printers. Desc commodity plastic, improved mechanical and thermal properties compared to pla. We produce hundreds of thousands of plastic parts with our printers. This 3d plastic printing technology is great for spare parts, prototypes and functional components. Plastics and metals are two most popular 3d printing material. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. These properties make abs very suitable for 3d printing. Select a plastic material and 3d explore the best printers in the industry. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. Resulting parts have a high surface quality and properties range from elastic to stiff. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. 3d systems invented 3d printing. At this point, the melted filament is homogenously the properties of biofila are amazing.

3d Printing Plastics Market Size Industry Report 2018 2025 , Also, Since Sla Materials Are Sensitive To Uv Light, Their Mechanical Properties Can Change Due To Overexposure To Sunlight, Thus Making Them Unsuitable Consumer Goods Companies Are Increasingly Eyeing Plastic 3D Printing As An Option For Mass Customisation.

3d Printing With Thermoplastics Key Considerations Stratasys Direct. Plastics and metals are two most popular 3d printing material. At this point, the melted filament is homogenously the properties of biofila are amazing. Desc commodity plastic, improved mechanical and thermal properties compared to pla. A wide range of 3d printing plastic materials from thermoplastics for functional parts to high detail resins (thermosets) for visual prototypes. The printing technology consists in inserting a plastic filament through an extruder that warms it until to melting. 3d systems invented 3d printing. You can also cast two materials on top of each other, resulting in a combination of hard and elastic parts in a single model. These properties make abs very suitable for 3d printing. Select a plastic material and 3d explore the best printers in the industry. It is similar to the material used in biodegradable plastic packaging and melts at between 180 and 200 degrees c, depending. Resulting parts have a high surface quality and properties range from elastic to stiff. Polylactic acid (pla) is a polymer plastic, made from biological materials like cornstarch or sugarcane. We produce hundreds of thousands of plastic parts with our printers. In the world of 3d printing, pva isn't necessarily used to make the finished product, but rather to create a support structure for portions of a product that may warp or collapse. This 3d plastic printing technology is great for spare parts, prototypes and functional components.