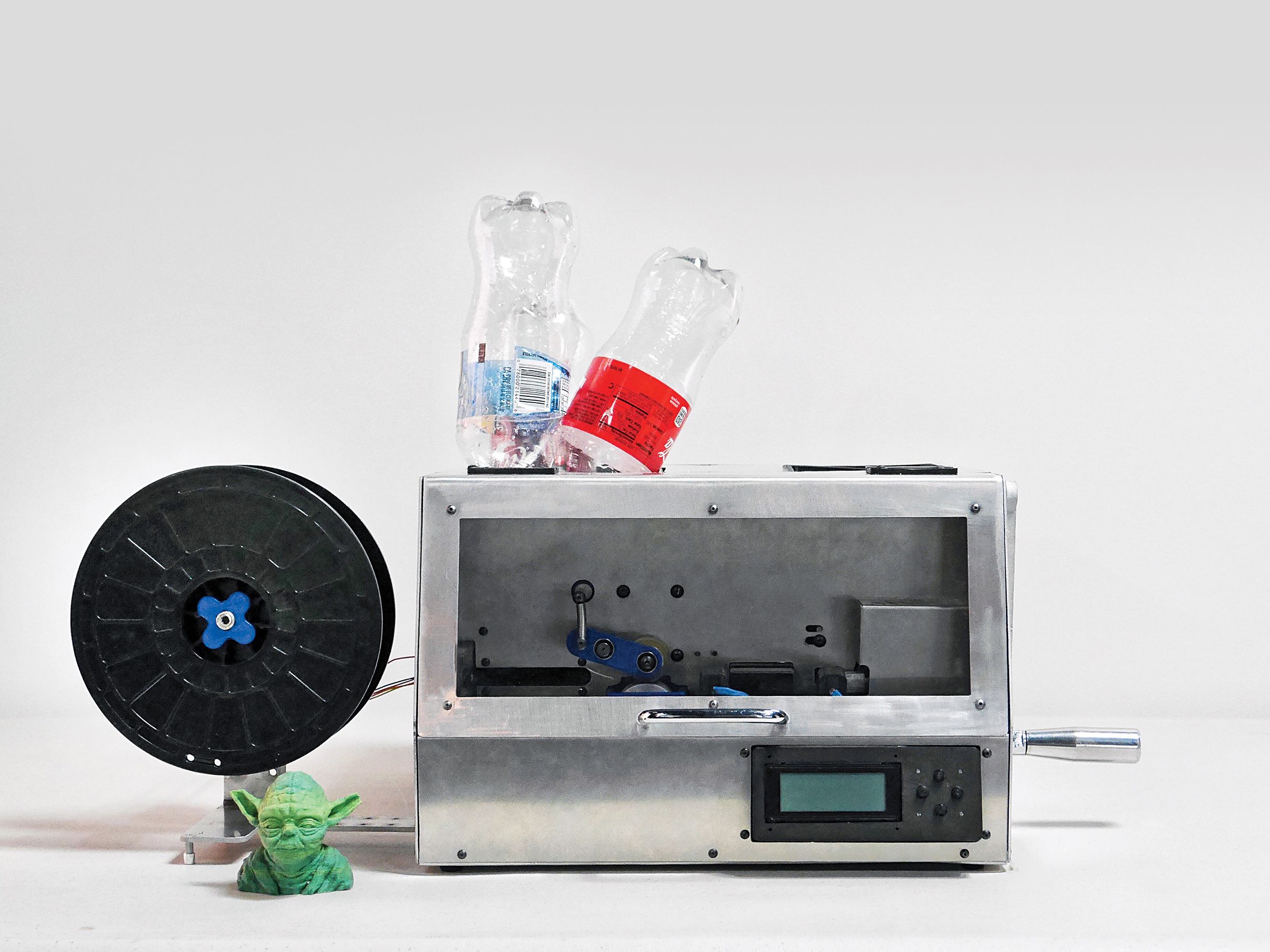

3D Printing Plastic Recycling. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. 3d printer recycling plastic technology. You recycle plastic by putting it through a plastic grinder. What types of plastic are recyclable? Protocycler is the first and only system for recycling waste plastic into new filament. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. There are a few drawbacks to recycled plastic. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. Customize the colours and materials of your 3d printer. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. This won't be the only post on this subject. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. Our filament makers streamline innovation for engineers. Is 3d printer filament recyclable?

3D Printing Plastic Recycling - Hardwarex 4C (2018) E00026 Doi:

Renegade Is The Pen That Recycles Plastic Bottles Into 3d Printed Sculptures Recycle Plastic Bottles Plastic Bottles 3d Pen. Protocycler is the first and only system for recycling waste plastic into new filament. Our filament makers streamline innovation for engineers. Customize the colours and materials of your 3d printer. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. This won't be the only post on this subject. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. You recycle plastic by putting it through a plastic grinder. 3d printer recycling plastic technology. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. There are a few drawbacks to recycled plastic. What types of plastic are recyclable? Is 3d printer filament recyclable?

The plastic waste of the population has been taken and recycled to be transformed into 3d printing material.

In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. Reflow filament is made from recycled pet bottles collected in developing regions, and revenues from the filament go back to the waste collectors who gather these bottles, which the company claims can. The dutch association, the new raw, wants to go. 3d printing translates your creative ideas into physical reality. As 3d printing becomes more popular, plastic production and consumption will increase, causing many environmental impacts. 3d printer recycling plastic technology. Devices like the 3doodler which turn plastic filaments into a gel that hardens in the air — letting users create impressive freehand sculptures in the process. You recycle plastic by putting it through a plastic grinder. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Hardwarex 4c (2018) e00026 doi: Recycle plastic into filament creating a closed loop recycling system. Protocycler is the first and only system for recycling waste plastic into new filament. I was getting tired of cutting up failed parts and my research materials by hand. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. But now the filabot, a miniature plastic recycling plant, will provide a wide variety of plastic filaments from scrap. Using something like this 3d printer filament factory (filament extruder). In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. Follow 3d printing society podcast to never miss another show. Regarding technical challenges, i can only guess. Go green, prints like a dream. Customize the colours and materials of your 3d printer. The goal is that recycling is not only desirable. Reflow converts recyclable plastic into 3d printing filament using open source technology. From our workshop in the north of amsterdam, we change the way we deal with plastic waste. By using it as a resource, vanplestik that's why we developed a 3d printer especially made to recycle plastic waste streams. The first integrated 3d printer and recycler is part of the cargo that was launched to the international space station on northrop grumman's cygnus spacecraft's 10 th commercial the demonstration will use control plastic recycled multiple times to create parts that will be tested for quality back on earth. The city was able to create all kinds of original shapes and offer durable furniture, providing significant added value to the plastic waste. Our filament makers streamline innovation for engineers. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. From there you can remold it into whatever you want.

Recycling Plastic For 3d Printing Why Not The Default Real Driver Park , There Are A Few Options For Grinding Up Failed Printed Parts For Turning Them Back Into Filament.

5 Ways To Reduce Waste At The Coffee Shop Plastic Waste Recycling Recycled Plastic. Our filament makers streamline innovation for engineers. You recycle plastic by putting it through a plastic grinder. What types of plastic are recyclable? There are a few drawbacks to recycled plastic. Is 3d printer filament recyclable? Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. This won't be the only post on this subject. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. 3d printer recycling plastic technology. Protocycler is the first and only system for recycling waste plastic into new filament. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. Customize the colours and materials of your 3d printer.

Guide To Green 3d Printing 4 Ways To Be More Sustainable , Hardwarex 4C (2018) E00026 Doi:

Shr3d It Compact Plastic Shredder And Recycler 3devo. This won't be the only post on this subject. There are a few drawbacks to recycled plastic. Our filament makers streamline innovation for engineers. Protocycler is the first and only system for recycling waste plastic into new filament. Is 3d printer filament recyclable? The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. You recycle plastic by putting it through a plastic grinder. What types of plastic are recyclable?

Filabot 3d Printing Filament Maker By Tyler Mcnaney . Using something like this 3d printer filament factory (filament extruder).

How To Make Your Own Filament By Recycling Old 3d Prints Part 2 3d Printing Talk Manufacturing 3d Hubs. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. You recycle plastic by putting it through a plastic grinder. 3d printer recycling plastic technology. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Customize the colours and materials of your 3d printer. There are a few drawbacks to recycled plastic. Is 3d printer filament recyclable? What types of plastic are recyclable? Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. Protocycler is the first and only system for recycling waste plastic into new filament. Our filament makers streamline innovation for engineers. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. This won't be the only post on this subject.

Will 3d Printers Be The Future Of Plastic Recycling - As 3D Printing Becomes More Popular, Plastic Production And Consumption Will Increase, Causing Many Environmental Impacts.

Filament Maker Recycle Filament For Any 3d Printer Filabot. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. You recycle plastic by putting it through a plastic grinder. This won't be the only post on this subject. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. What types of plastic are recyclable? Protocycler is the first and only system for recycling waste plastic into new filament. Our filament makers streamline innovation for engineers. 3d printer recycling plastic technology. Customize the colours and materials of your 3d printer. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. There are a few drawbacks to recycled plastic. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. Is 3d printer filament recyclable? When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products.

Filabot 3d Printing Filament Maker By Tyler Mcnaney - Regarding Technical Challenges, I Can Only Guess.

Reflow Helps Waste Collectors Earn A Living By Turning Plastic Trash Into 3d Printer Filament. 3d printer recycling plastic technology. What types of plastic are recyclable? 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. Customize the colours and materials of your 3d printer. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. Our filament makers streamline innovation for engineers. Protocycler is the first and only system for recycling waste plastic into new filament. Is 3d printer filament recyclable? You recycle plastic by putting it through a plastic grinder. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. There are a few drawbacks to recycled plastic. This won't be the only post on this subject.

Could 3d Printing Reduce Plastic Waste , From Our Workshop In The North Of Amsterdam, We Change The Way We Deal With Plastic Waste.

Pet Recycling From Plastic Bottles To 3d Printing Filament 3devo Blog. You recycle plastic by putting it through a plastic grinder. Is 3d printer filament recyclable? Customize the colours and materials of your 3d printer. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Our filament makers streamline innovation for engineers. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. 3d printer recycling plastic technology. Protocycler is the first and only system for recycling waste plastic into new filament. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. There are a few drawbacks to recycled plastic. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. This won't be the only post on this subject. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. What types of plastic are recyclable? The machine works by recycling plastic bottles and converting them into raw materials for 3d printing.

Is 3d Printing Increasing The Plastic Pollution Problem : 3D Printer Part Recycling Grinder:

3d Re Printer Concept All In One Plastic Recycling 3d Printer 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Protocycler is the first and only system for recycling waste plastic into new filament. You recycle plastic by putting it through a plastic grinder. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. Customize the colours and materials of your 3d printer. 3d printer recycling plastic technology. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Is 3d printer filament recyclable? This won't be the only post on this subject. What types of plastic are recyclable? In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. There are a few drawbacks to recycled plastic. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Our filament makers streamline innovation for engineers.

Renegade Is The Pen That Recycles Plastic Bottles Into 3d Printed Sculptures Recycle Plastic Bottles Plastic Bottles 3d Pen - 3D Printing Translates Your Creative Ideas Into Physical Reality.

How To Make Your Own Filament By Recycling Old 3d Prints Part 2 3d Printing Talk Manufacturing 3d Hubs. You recycle plastic by putting it through a plastic grinder. What types of plastic are recyclable? Our filament makers streamline innovation for engineers. Is 3d printer filament recyclable? In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. There are a few drawbacks to recycled plastic. This won't be the only post on this subject. Protocycler is the first and only system for recycling waste plastic into new filament. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. 3d printer recycling plastic technology. Customize the colours and materials of your 3d printer.

Recycle Failed And Waste 3d Prints Challenges Filamentive - The Plastic Oceans Chile Team Visits The Qactus Office.

Will 3d Printers Be The Future Of Plastic Recycling. 3d printer recycling plastic technology. You recycle plastic by putting it through a plastic grinder. Is 3d printer filament recyclable? Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. This won't be the only post on this subject. Customize the colours and materials of your 3d printer. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Our filament makers streamline innovation for engineers. Protocycler is the first and only system for recycling waste plastic into new filament. What types of plastic are recyclable? Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. There are a few drawbacks to recycled plastic.

Pet Recycled Filament 3d Printing Blog . Protocycler Is The First And Only System For Recycling Waste Plastic Into New Filament.

Polyethylene Terephthalate Plastic Bottle 3d Printing Filament Pet Bottle Recycling Spool Recycling Waste Png Pngegg. Protocycler is the first and only system for recycling waste plastic into new filament. In a subject i'm very keen to promote, this time we are looking at recycling of plastic into filaments for 3d printing. 3d printing with pellets provides an alternative way to develop objects instead of reverting to plastic filaments. Our shredder is a localized plastic recycling solution, coupling industrial recycling technology with low energy consumption. What types of plastic are recyclable? This won't be the only post on this subject. There are a few drawbacks to recycled plastic. Is 3d printer filament recyclable? Customize the colours and materials of your 3d printer. 3d printer recycling plastic technology. When plastic is sent to a recycling center, it gets washed, sorted, shredded, and then melted into small pellets, which are then used as raw material for the manufacturing of new products. The machine works by recycling plastic bottles and converting them into raw materials for 3d printing. Our filament makers streamline innovation for engineers. Although the protocycler's filament starts out with about the same strength as the standard stuff, it gets none of that is a big deal if you're using the printer to rapidly prototype designs, when quantity matters more than quality. You recycle plastic by putting it through a plastic grinder.