3D Printing Plastic Strength. Different 3d printing materials support different combinations of toughness and tensile strength. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Thinner layers have more extrusions of material per part, but the strands have a. *(nobody loves the smell of heated plastic; So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Tensile strength is the measurement of a material's resilience. Mmm, who loves the smell of freshly baked prints? *. So let's get on with it and start talking about our materials. High strength plastics and metals with tensile strength greater than 45 mpa. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. Flexural strength of traditional and 3d printed materials, measured in mpa: I choose a lattice type fill while printing leaving quite emty space in the printed part.

3D Printing Plastic Strength , Generally, You Would Print A Pla Case Around The Parts That Conduct Electricity To Protect It And Give It More Strength.

3d Printing Filament Flexible Plastic Strength Flexible Wire Printer Supplies Ebay. Flexural strength of traditional and 3d printed materials, measured in mpa: Thinner layers have more extrusions of material per part, but the strands have a. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. *(nobody loves the smell of heated plastic; Different 3d printing materials support different combinations of toughness and tensile strength. I choose a lattice type fill while printing leaving quite emty space in the printed part. So let's get on with it and start talking about our materials. High strength plastics and metals with tensile strength greater than 45 mpa. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Mmm, who loves the smell of freshly baked prints? *. Tensile strength is the measurement of a material's resilience.

Before 3d printing with asa make sure your 3d printer meets the hardware requirements listed below to ensure the best print quality.

Usually it means that it is much easier to use in the most common desktop fdm 3d printers: Aside from 3d printing, other products that use pla. So let's get on with it and start talking about our materials. Choose from plastic and metal 3d printing for extremely accurate prototypes and fully functional our industrial 3d printing service ensures accuracy and repeatability so you get highly precise parts—every time. High strength plastics and metals with tensile strength greater than 45 mpa. Hence why fdm prints are porous and why the tensile strength is low. Tensile strength is the measurement of a material's resilience. Today, we are going to go on with the differences of the most common 3d printing materials, the abs and pla plastics. But as for the elongation at break, you can expect these printing materials to have the same performance as. It is these crystals that cause the plastic part to be prone to failure. Consumer goods companies are increasingly eyeing plastic 3d printing as an option for mass customisation. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Well, high impact polystyrene (hips) is great for this. Select a plastic material and 3d explore the best printers in the industry. You can infuse the fdm print with epoxy to help increase strength, but its a i am using fdm printer and have the some problem with strength in z axis direction. Unlike abs, pla deforms definitely less and suffers from very little layer detachment. Learn everything about 3d printing in versatile plastic: In this article we're going to explain what 3d printer annealing actually is (hint: Of course, plastic is the substance that first made 3d printing of any kind possible, and plastic remains one of the most common and versatile polylactic acid (pla) — it's probably no surprise that one of the most commonly used bioplastics in the world would also dominate in 3d printing. Acrylonitrile butadiene styrene (abs) is the same plastic used in legos. When it comes to strength, pla filaments have greater tensile strength. Different 3d printing materials support different combinations of toughness and tensile strength. Flexural strength of traditional and 3d printed materials, measured in mpa: Tips, design rules, technical documentation versatile plastic is a durable nylon plastic that can be used for a wide range of applications, both high strength & stiffness applications. Better strength to weight ratio. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Before 3d printing with asa make sure your 3d printer meets the hardware requirements listed below to ensure the best print quality. The material is ideal for device parts that need to be flexible, such as touchscreens. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Polycarbonate is known for its strength and durability. Consequently, plastics are set to become the most environmentally friendly option in 3d printing.

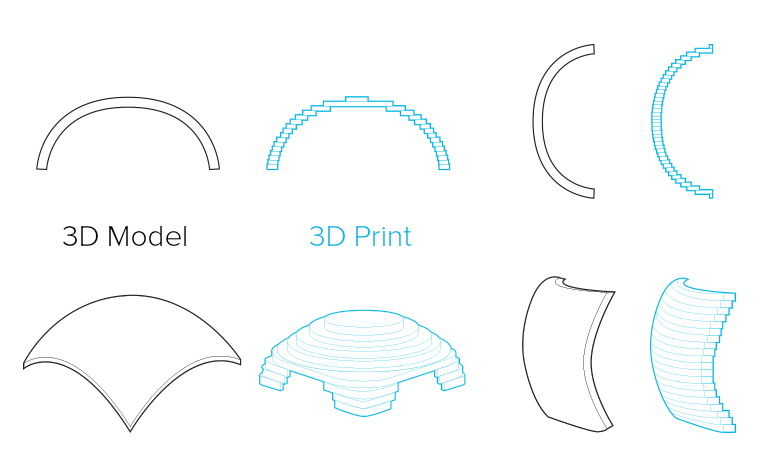

3d Printing And Traditional Manufacturing Processes - Thinner Layers Have More Extrusions Of Material Per Part, But The Strands Have A.

3d Printed Reinforced Plastic Parts Stronger Than Aluminium. Thinner layers have more extrusions of material per part, but the strands have a. So let's get on with it and start talking about our materials. High strength plastics and metals with tensile strength greater than 45 mpa. I choose a lattice type fill while printing leaving quite emty space in the printed part. Mmm, who loves the smell of freshly baked prints? *. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Flexural strength of traditional and 3d printed materials, measured in mpa: Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Tensile strength is the measurement of a material's resilience. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. *(nobody loves the smell of heated plastic; Different 3d printing materials support different combinations of toughness and tensile strength.

3d Printing Materials Terminology And Specifications 3d Printing Materials 3d Printing Fast Print , The Inside Consists Of A What 3D Prints Are Use For Depends On The Material Used, But Many Fdm 3D Printed Plastic Parts Are Great For Prototypes, Rough Spare Parts And Tools.

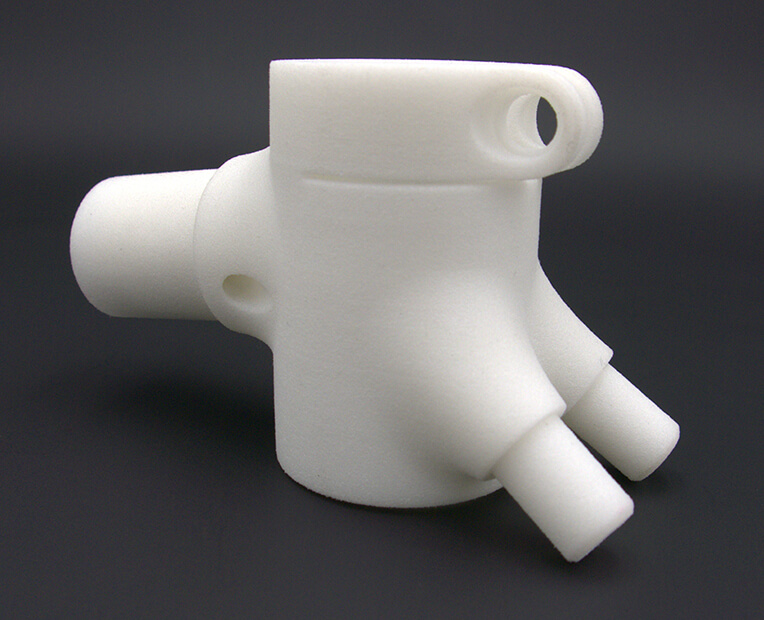

High Strength 3d Printing 3d Hubs. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Tensile strength is the measurement of a material's resilience. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Mmm, who loves the smell of freshly baked prints? *. Different 3d printing materials support different combinations of toughness and tensile strength. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. *(nobody loves the smell of heated plastic; Flexural strength of traditional and 3d printed materials, measured in mpa: Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. To reduce printing time and material consumption, typically only the outer walls are printed in full strength.

What Is The Strongest 3d Printer Filament Airwolf 3d - Aside from 3d printing, other products that use pla.

Hot Petg 1 75mm 1kg Plastic 3d Printing High Strength 3d Printer Filament Sale Price Reviews Gearbest. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Mmm, who loves the smell of freshly baked prints? *. Flexural strength of traditional and 3d printed materials, measured in mpa: High strength plastics and metals with tensile strength greater than 45 mpa. So let's get on with it and start talking about our materials. *(nobody loves the smell of heated plastic; I choose a lattice type fill while printing leaving quite emty space in the printed part. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Thinner layers have more extrusions of material per part, but the strands have a. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Tensile strength is the measurement of a material's resilience. Different 3d printing materials support different combinations of toughness and tensile strength.

How To Use 3d Print Infill Settings Increase Strength Save Filament , But What About 3D Printing Using Ps?

3d Printing Vs Injection Tensile Strength Comparison. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Different 3d printing materials support different combinations of toughness and tensile strength. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Thinner layers have more extrusions of material per part, but the strands have a. High strength plastics and metals with tensile strength greater than 45 mpa. So let's get on with it and start talking about our materials. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Mmm, who loves the smell of freshly baked prints? *. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Tensile strength is the measurement of a material's resilience. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. I choose a lattice type fill while printing leaving quite emty space in the printed part. Flexural strength of traditional and 3d printed materials, measured in mpa: Best upgrade for flyingbear ghost 5, 3d printer heat chamber. *(nobody loves the smell of heated plastic;

3d Printing Materials The Pros And Cons Of Each Type Tom S Guide : Unlike Abs, Pla Deforms Definitely Less And Suffers From Very Little Layer Detachment.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Printing 3d Printer 3d Printing Business. So let's get on with it and start talking about our materials. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. High strength plastics and metals with tensile strength greater than 45 mpa. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Different 3d printing materials support different combinations of toughness and tensile strength. Tensile strength is the measurement of a material's resilience. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Mmm, who loves the smell of freshly baked prints? *. Thinner layers have more extrusions of material per part, but the strands have a. I choose a lattice type fill while printing leaving quite emty space in the printed part. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Flexural strength of traditional and 3d printed materials, measured in mpa: *(nobody loves the smell of heated plastic;

How Annealing Makes Your 3d Prints Better Fargo 3d Printing : Ultem Is A Family Of Pei Products Manufactured By Sabic As A Result Of Acquiring The General Electric Plastics Division In 2007.

Pc A Polycarbonate Thermoplastic 3d Printing Material Stratasys. I choose a lattice type fill while printing leaving quite emty space in the printed part. *(nobody loves the smell of heated plastic; To reduce printing time and material consumption, typically only the outer walls are printed in full strength. So let's get on with it and start talking about our materials. Tensile strength is the measurement of a material's resilience. Thinner layers have more extrusions of material per part, but the strands have a. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Mmm, who loves the smell of freshly baked prints? *. High strength plastics and metals with tensile strength greater than 45 mpa. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Flexural strength of traditional and 3d printed materials, measured in mpa: The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Different 3d printing materials support different combinations of toughness and tensile strength. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007.

Composite 3d Printing An Emerging Technology With A Bright Future Amfg : Learn Everything About 3D Printing In Versatile Plastic:

Optimizing Strength Of 3d Printed Parts 3dpros. Thinner layers have more extrusions of material per part, but the strands have a. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Flexural strength of traditional and 3d printed materials, measured in mpa: Tensile strength is the measurement of a material's resilience. I choose a lattice type fill while printing leaving quite emty space in the printed part. Different 3d printing materials support different combinations of toughness and tensile strength. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Mmm, who loves the smell of freshly baked prints? *. *(nobody loves the smell of heated plastic; Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. So let's get on with it and start talking about our materials. High strength plastics and metals with tensile strength greater than 45 mpa.

Amazon Com Purple Transparent Color 3d Printer Filaments Pla 1 75mm 1kg Plastic Rubber Consumables Material Makerbot Reprap Up Mendel Everything Else , Graphene Has Become A Popular Choice For 3D Printing Because Of Its Strength And Conductivity.

Optimizing Strength Of 3d Printed Parts 3dpros. Flexural strength of traditional and 3d printed materials, measured in mpa: Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. So let's get on with it and start talking about our materials. Mmm, who loves the smell of freshly baked prints? *. Tensile strength is the measurement of a material's resilience. Thinner layers have more extrusions of material per part, but the strands have a. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Different 3d printing materials support different combinations of toughness and tensile strength. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. *(nobody loves the smell of heated plastic; Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. High strength plastics and metals with tensile strength greater than 45 mpa. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. I choose a lattice type fill while printing leaving quite emty space in the printed part.

Industrial Strength Fdm Materials From Basf 3d Printing Solutions All3dp - One Of The Reasons Is Mainly Because Polypropylene Most 3D Printers Find It Hard To Control The Results Of Pp Prints Because Of The Heavy Warping That Takes Place.

Introduction To Fdm 3d Printing 3d Hubs. High strength plastics and metals with tensile strength greater than 45 mpa. I choose a lattice type fill while printing leaving quite emty space in the printed part. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. Mmm, who loves the smell of freshly baked prints? *. Best upgrade for flyingbear ghost 5, 3d printer heat chamber. Flexural strength of traditional and 3d printed materials, measured in mpa: Different 3d printing materials support different combinations of toughness and tensile strength. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. Thinner layers have more extrusions of material per part, but the strands have a. Tensile strength is the measurement of a material's resilience. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. *(nobody loves the smell of heated plastic; So let's get on with it and start talking about our materials. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools.

18 3d Printer Filament Types And Uses Comparison Guide Oct 2020 , Of Course, Plastic Is The Substance That First Made 3D Printing Of Any Kind Possible, And Plastic Remains One Of The Most Common And Versatile Polylactic Acid (Pla) — It's Probably No Surprise That One Of The Most Commonly Used Bioplastics In The World Would Also Dominate In 3D Printing.

Polypropylene Vs Pla Why Is One Better For 3d Printing Fargo 3d Printing. I choose a lattice type fill while printing leaving quite emty space in the printed part. So let's get on with it and start talking about our materials. High strength plastics and metals with tensile strength greater than 45 mpa. *(nobody loves the smell of heated plastic; Ultem is a family of pei products manufactured by sabic as a result of acquiring the general electric plastics division in 2007. To reduce printing time and material consumption, typically only the outer walls are printed in full strength. The inside consists of a what 3d prints are use for depends on the material used, but many fdm 3d printed plastic parts are great for prototypes, rough spare parts and tools. Flexural strength of traditional and 3d printed materials, measured in mpa: Best upgrade for flyingbear ghost 5, 3d printer heat chamber. So extra holes and negative details that provide holding points for the cured epoxy is mandatory. Mmm, who loves the smell of freshly baked prints? *. Different 3d printing materials support different combinations of toughness and tensile strength. Whether plastic or composite, fff or cff, 3d printed parts are strongest in planes parallel to the print bed — so the print orientation can literally layer height in 3d printing doesn't substantially affect part strength. Thinner layers have more extrusions of material per part, but the strands have a. Tensile strength is the measurement of a material's resilience.