3D Printing Problems With Abs. First off printing abs requires a heated build chamber for optimal results. Print doesn't stick to print bed. Fdm 3d printing problems abs is more common however, so we'll use it here. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. However, don't be too quick to assume the problem is in your abs. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. This material was one of the first plastics to be used with industrial. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. A lot of problems with printing small abs objects come down to heat management. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? 3d printing problems with abs. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament.

3D Printing Problems With Abs . First, Abs Prints At A Higher Temperature Than Other Plastics, Around 230°C.

Common Problems In 3d Printing How To Resolve Them Part I Manufactur3d. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? First off printing abs requires a heated build chamber for optimal results. 3d printing problems with abs. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Print doesn't stick to print bed. However, don't be too quick to assume the problem is in your abs. A lot of problems with printing small abs objects come down to heat management. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. Fdm 3d printing problems abs is more common however, so we'll use it here. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. This material was one of the first plastics to be used with industrial.

Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures.

Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. First, abs prints at a higher temperature than other plastics, around 230°c. 1) maximum heat for your particular filament (note that not all filaments. At the base of the model, the print bends upwards until it's no longer level with the print platform. There are no problems with printing small models, but with large models having constant problems: The problem of warping arises if the plastic is cooled too quickly. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. As the abs or pla filament cools it starts to contract very slightly; As you know, printing in 3d is empirical, it is through errors break possible improper sealing of the nozzle causes burnt pla or abs to leak around the nozzle. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. Many common 3d printing problems stem from a poor first layer. To print abs, except for very small parts, you need closed printers that maintain a warm environment around the part. Pla is not as sensitive to temperature changes as abs, and this means less problems with warping. Abs slurries work great for abs prints. If you are interested in printing any sizable parts an enclosure is highly recommended. We offer advice that should help you solve the problem. First off printing abs requires a heated build chamber for optimal results. I print abs in my basement in an unenclosed prusa3d i3m3s, just as i print other filaments. A lot of problems with printing small abs objects come down to heat management. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Fortunately, zmorph vx comes with magnetic covers and therefore 3d printing with abs is also possible. No problems related to lack of enclosure. An enclosure will help to maintain a consistent heat within the build volume. Print doesn't stick to print bed. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. Since abs has a high shrinkage rate which causes warping, we will only print larger abs jobs with our ***disclaimer: Perhaps an enclosure would be helpful, but i don't have problems as it is. Polylactide is also better for detailed models. The problem arises when printing large parts. By mixing acetone with some abs filament you can create a slurry you can paint on your print bed your 3d printer is a mechanical device, therefore;

3d Print Quality Troubleshooting Hydra Research - After Problems With Curling And Moving Part I Did Everything You Guys Said And Printed 3 Parts Without Problems.

All You Need To Know About Abs For 3d Printing 3dnatives. This material was one of the first plastics to be used with industrial. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. 3d printing problems with abs. However, don't be too quick to assume the problem is in your abs. A lot of problems with printing small abs objects come down to heat management. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Print doesn't stick to print bed. First off printing abs requires a heated build chamber for optimal results. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Fdm 3d printing problems abs is more common however, so we'll use it here. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world.

The Definitive Guide To Solving 3d Printing Problems By Bitfab Bitfab : A Lot Of Problems With Printing Small Abs Objects Come Down To Heat Management.

Troubleshooting Guide To 19 Common 3d Printing Problems Part One Geeetech Blog. A lot of problems with printing small abs objects come down to heat management. However, don't be too quick to assume the problem is in your abs. This material was one of the first plastics to be used with industrial. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Abs is one of the most commonly used, and most versatile materials available in 3d printing today. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Print doesn't stick to print bed.

3d Print Quality Troubleshooting Hydra Research - To print abs, except for very small parts, you need closed printers that maintain a warm environment around the part.

How To Solve The Most Common 3d Printing Problems 3d Printing For Beginners. This material was one of the first plastics to be used with industrial. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? First off printing abs requires a heated build chamber for optimal results. However, don't be too quick to assume the problem is in your abs. Fdm 3d printing problems abs is more common however, so we'll use it here. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. 3d printing problems with abs. A lot of problems with printing small abs objects come down to heat management. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Print doesn't stick to print bed. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity.

Why Keep Using Abs In 3d Printing Abs Guide Applications Pros And Cons Bitfab : We Offer Advice That Should Help You Solve The Problem.

How To Succeed When Printing With Abs Matterhackers. First off printing abs requires a heated build chamber for optimal results. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. However, don't be too quick to assume the problem is in your abs. Print doesn't stick to print bed. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. This material was one of the first plastics to be used with industrial. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. 3d printing problems with abs. A lot of problems with printing small abs objects come down to heat management. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Fdm 3d printing problems abs is more common however, so we'll use it here. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. Abs is one of the most commonly used, and most versatile materials available in 3d printing today.

What Is The Asa In 3d Printing . With The Right Settings And Patience Hobbyists Have Succeeded In Printing All Sorts Of Materials Many Of Which Have Very Low Viscosity.

Identify And Correct 3d Printing Problems Cults. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. A lot of problems with printing small abs objects come down to heat management. 3d printing problems with abs. Print doesn't stick to print bed. This material was one of the first plastics to be used with industrial. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Fdm 3d printing problems abs is more common however, so we'll use it here. However, don't be too quick to assume the problem is in your abs. First off printing abs requires a heated build chamber for optimal results. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c.

Common 3d Printing Problems And How To Solve Them , With The Right Settings And Patience Hobbyists Have Succeeded In Printing All Sorts Of Materials Many Of Which Have Very Low Viscosity.

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Abs is one of the most commonly used, and most versatile materials available in 3d printing today. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. A lot of problems with printing small abs objects come down to heat management. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. This material was one of the first plastics to be used with industrial. First off printing abs requires a heated build chamber for optimal results. Fdm 3d printing problems abs is more common however, so we'll use it here. Print doesn't stick to print bed. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. 3d printing problems with abs. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. However, don't be too quick to assume the problem is in your abs.

A Visual Ultimaker Troubleshooting Guide 3dverkstan Knowledge Base , Fdm 3D Printing Problems Abs Is More Common However, So We'lL Use It Here.

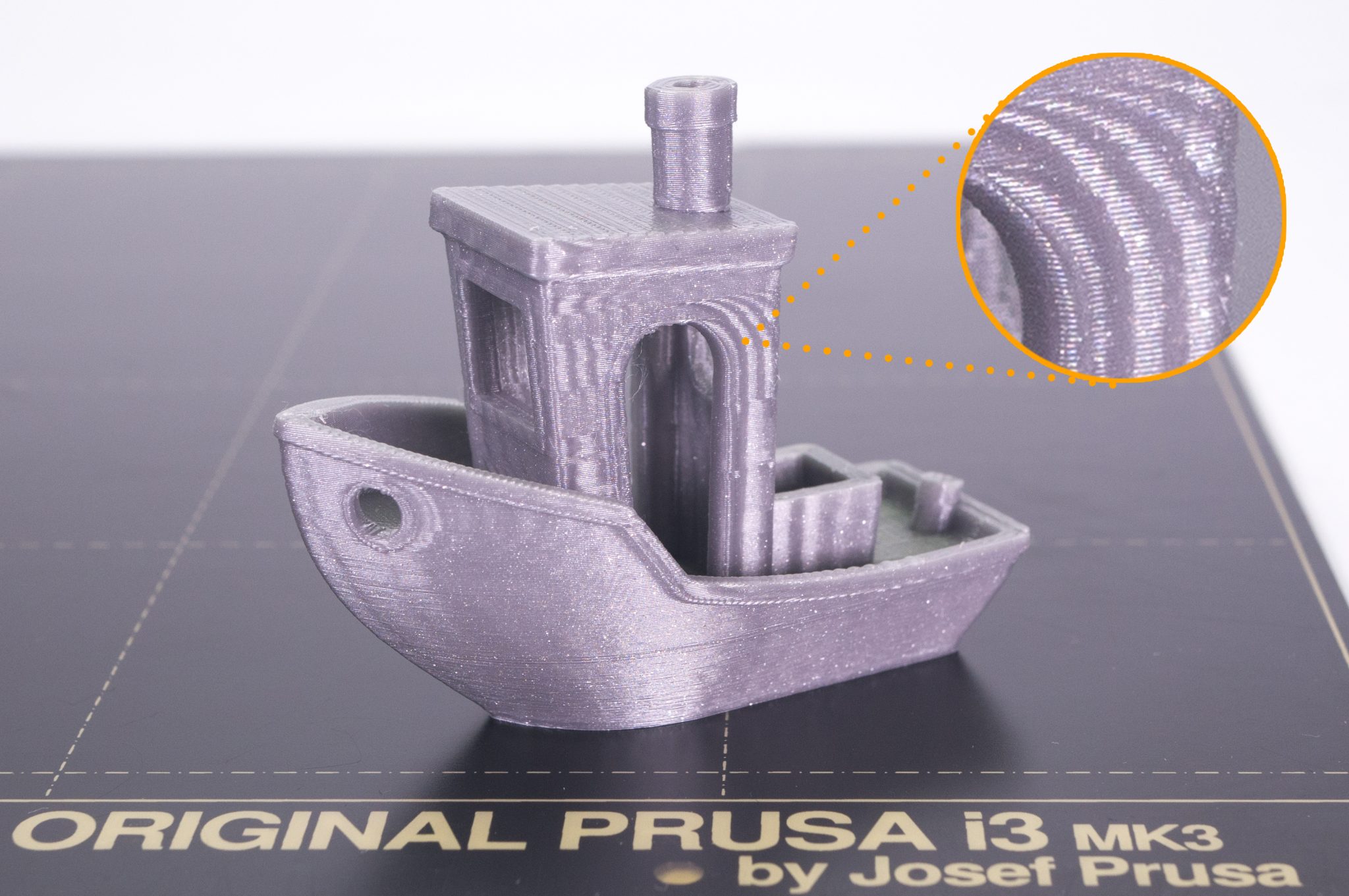

7 Problems Affecting The Quality Of Your 3d Prints Prusa Printers. Fdm 3d printing problems abs is more common however, so we'll use it here. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. However, don't be too quick to assume the problem is in your abs. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. First off printing abs requires a heated build chamber for optimal results. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. A lot of problems with printing small abs objects come down to heat management. 3d printing problems with abs. This material was one of the first plastics to be used with industrial. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world. Print doesn't stick to print bed.

Why Can T I Get 3d Printed Parts To Stick To The Bed Airwolf 3d . After Problems With Curling And Moving Part I Did Everything You Guys Said And Printed 3 Parts Without Problems.

3d Printing Technology Explained 3d Printing For Beginners. 3d printing problems with abs. Print doesn't stick to print bed. First off printing abs requires a heated build chamber for optimal results. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. However, don't be too quick to assume the problem is in your abs. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. This material was one of the first plastics to be used with industrial. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? A lot of problems with printing small abs objects come down to heat management. Fdm 3d printing problems abs is more common however, so we'll use it here. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world.

Warping And Cracking With Closed Environment Fdm 3d Printers Box3d , The Following Abs Settings Are For Cura And Work Well On Lulzbot Taz Printers With An E3D Hotend.

The Definitive Guide To Solving 3d Printing Problems By Bitfab Bitfab. 3d printing problems with abs. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? Print doesn't stick to print bed. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. However, don't be too quick to assume the problem is in your abs. This material was one of the first plastics to be used with industrial. Fdm 3d printing problems abs is more common however, so we'll use it here. A lot of problems with printing small abs objects come down to heat management. First off printing abs requires a heated build chamber for optimal results. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world.

Top 5 Things To Know About 3d Printing Abs Parts - We Have Used These Settings On Our.

3d Printer Troubleshooting Guide Warping Youtube. To print regular abs you will require a printer equipped with a heated bed that can heat up to 90°c. Depending on which filament you use, layer separation can be a small or a large with these helpful steps, alec will teach you everything you need to know about how to 3d print with abs filament. A lot of problems with printing small abs objects come down to heat management. Abs is one of the most commonly used, and most versatile materials available in 3d printing today. You need to build an enclosure around your printer to trap the heat from the printer itself if you i assume this is a fairly small object? However, don't be too quick to assume the problem is in your abs. First off printing abs requires a heated build chamber for optimal results. Fdm 3d printing problems abs is more common however, so we'll use it here. 3d printing problems with abs. In this episode of the 3d printing update, i talk about some of the problems of 3d printing with abs, how i solved them, as well as showing anyone new to. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. With the right settings and patience hobbyists have succeeded in printing all sorts of materials many of which have very low viscosity. This material was one of the first plastics to be used with industrial. Print doesn't stick to print bed. Improve your print quality with advice from our abs (acrylonitrile butadiene styrene) has a long history in the 3d printing world.