3D Printing Process In Rapid Prototyping. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. It shows the working phenomenon of 3d printer. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. It works on the principle of streolithography. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. This kind of rapid prototype is particularly informative since the master model used. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. It is also known as rapid prototyping. But, some people think that these two are the same. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. 3d printing and rapid prototyping are technologies used in additive manufacturing. Were explored by 3d printing several versions of electronic. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products.

3D Printing Process In Rapid Prototyping : Construction Of The Part Or Assembly Is Usually Done Using 3D Printing Or Additive Layer Manufacturing Technology.

Rapid Prototyping The Evolution Of 3d Printing Amfg. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. It shows the working phenomenon of 3d printer. It is also known as rapid prototyping. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. Were explored by 3d printing several versions of electronic. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. It works on the principle of streolithography. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. This kind of rapid prototype is particularly informative since the master model used. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. 3d printing and rapid prototyping are technologies used in additive manufacturing. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. But, some people think that these two are the same. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry.

Rapid prototyping using 3d printing allows engineers and designers to execute inexpensive, quick rapid prototyping helps you discover design mistakes in the earliest stages of the development.

For example, the use of 'rapid prototyping' to describe the field is no longer relevant as the technology is now used for functional components as well. Learn how 3d printing makes it possible. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. Like many other 3d printing processes, the great advantage here is that parts can be made with complex geometries like internal lattice structures that would be difficult or impossible to do any other. 3d printing technologies continue to evolve rapidly, but not all are suited for rapid prototyping. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. For example, the use of 'rapid prototyping' to describe the field is no longer relevant as the technology is now used for functional components as well. Design, 3d print, iterate, repeat. This is a key attribute to downstream data processing because the more a part's features are defined in the scan data, the less manual time is. Rapid prototyping was the term used when i started using the process some 16 years ago and when it was only accessible to professionals in the product development business; It works on the principle of streolithography. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Rapid prototyping was the first application on the technology. 3d printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. 2 bringing prototyping to the modern era rapid prototyping techniques have found their place in a range of industries such as consumer goods and with inkjet based 3d printing the result is a more instructive and efficient prototyping process and at the end of the day, a better end product, more. Compare various 3d printing, cnc machining, and injection molding technologies to find a there are dozens of ways prototypes can be made. But, some people think that these two are the same. Besides rapid prototyping, 3d printing is also used for rapid manufacturing. It shows the working phenomenon of 3d printer. This kind of rapid prototype is particularly informative since the master model used. Rapid prototyping makes production processes more advanced, efficient, and effortless. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Rapid prototyping, which is often focused on 3d printing, is a modern method of product development that transfers efficiency benefits from manufacturing through to 3d printing can cost significantly less than the manufacturing processes traditionally used for prototyping, such as cnc machining. Rapid prototyping helps companies turn great ideas into successful products faster than ever before. Already ingrained for many years these companies are used to working with. Rapid prototyping & 3d printing is the next step in the development of 3d technology. Rapid prototyping using 3d printing allows engineers and designers to execute inexpensive, quick rapid prototyping helps you discover design mistakes in the earliest stages of the development. Rapid prototype or rapid prototyping is a relatively new term and in its simplest form, the process of creating prototypes quickly to visually and functionally so, what is the difference between rapid prototyping and 3d printing? For many organizations, rapid prototyping is an essential part of their design process. View this video, infographic and informative post.

Rapid Prototyping Services On Demand 3d Systems : They Are Both Essentially The Same.

3d Printing Rapid Prototyping Are They The Same. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Were explored by 3d printing several versions of electronic. This kind of rapid prototype is particularly informative since the master model used. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. It works on the principle of streolithography. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. It shows the working phenomenon of 3d printer. But, some people think that these two are the same. It is also known as rapid prototyping. 3d printing and rapid prototyping are technologies used in additive manufacturing.

Solved Hw Assignment Lesson 9 Rapid Prototyping 1 Explai Chegg Com , 3D Printing And Rapid Prototyping Are Technologies Used In Additive Manufacturing.

Rapid Prototyping An Overview Sciencedirect Topics. But, some people think that these two are the same. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. It is also known as rapid prototyping. This kind of rapid prototype is particularly informative since the master model used. It works on the principle of streolithography. It shows the working phenomenon of 3d printer. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Were explored by 3d printing several versions of electronic.

Rapid Prototyping Services In India Think3d , Rapid prototyping was the term used when i started using the process some 16 years ago and when it was only accessible to professionals in the product development business;

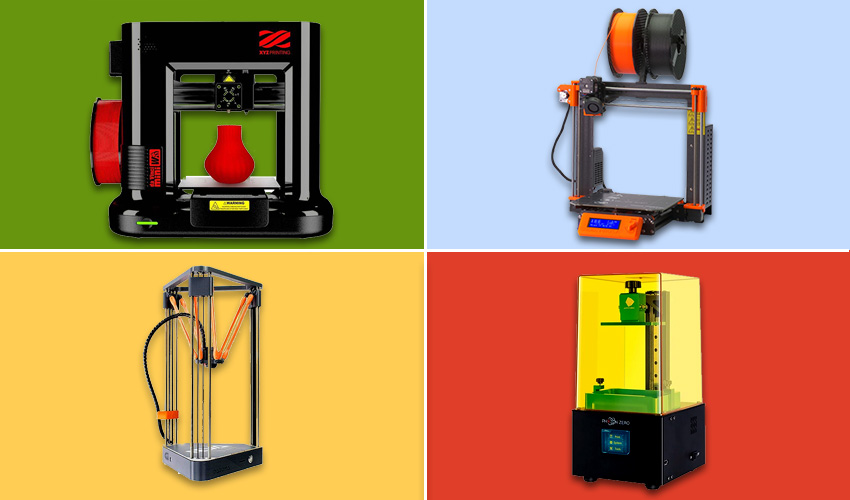

Introduction To Fused Filament Fabrication Fff 3d Printing Technology. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. Were explored by 3d printing several versions of electronic. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. This kind of rapid prototype is particularly informative since the master model used. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. It shows the working phenomenon of 3d printer. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. But, some people think that these two are the same. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. It is also known as rapid prototyping. It works on the principle of streolithography. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. 3d printing and rapid prototyping are technologies used in additive manufacturing.

3d Printing And Traditional Manufacturing Processes , For Example, The Use Of 'rApid Prototyping' To Describe The Field Is No Longer Relevant As The Technology Is Now Used For Functional Components As Well.

Custom 3d Printed Parts For Rapid Prototyping Product Design. This kind of rapid prototype is particularly informative since the master model used. 3d printing and rapid prototyping are technologies used in additive manufacturing. But, some people think that these two are the same. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. Were explored by 3d printing several versions of electronic. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. It shows the working phenomenon of 3d printer. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. It is also known as rapid prototyping. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. It works on the principle of streolithography.

3d Printing Service Rapid Prototyping In Portland Oregon Rapidmade - A Rapid Prototyping Machine Could Cost.

3d Printing And Traditional Manufacturing Processes. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. But, some people think that these two are the same. It shows the working phenomenon of 3d printer. It is also known as rapid prototyping. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. 3d printing and rapid prototyping are technologies used in additive manufacturing. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. This kind of rapid prototype is particularly informative since the master model used. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. It works on the principle of streolithography. Were explored by 3d printing several versions of electronic.

Rapid Prototype Technologies Overview Pdf , As Prototyping Processes Continue To Evolve, Product Designers Are Constantly Trying To Determine Which Method Or.

The Chunker Chunk Based Slicer Proposed For Cobot 3d Printing 3d Printing Industry. It works on the principle of streolithography. It is also known as rapid prototyping. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. But, some people think that these two are the same. It shows the working phenomenon of 3d printer. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. 3d printing and rapid prototyping are technologies used in additive manufacturing. This kind of rapid prototype is particularly informative since the master model used. Were explored by 3d printing several versions of electronic.

Product Development Process With Advanced Rapid Prototyping Techniques . It Shows The Working Phenomenon Of 3D Printer.

Why You Should Use A 3d Printer For Rapid Prototyping. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. 3d printing and rapid prototyping are technologies used in additive manufacturing. It is also known as rapid prototyping. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. It works on the principle of streolithography. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Were explored by 3d printing several versions of electronic. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. It shows the working phenomenon of 3d printer. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. This kind of rapid prototype is particularly informative since the master model used. But, some people think that these two are the same. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology.

Rapid Prototyping The Evolution Of 3d Printing Amfg . They Are Both Essentially The Same.

3d Printer Landing Page Template 3d Stock Illustration 1479115613. It shows the working phenomenon of 3d printer. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. It is also known as rapid prototyping. It works on the principle of streolithography. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. Were explored by 3d printing several versions of electronic. This kind of rapid prototype is particularly informative since the master model used. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. 3d printing and rapid prototyping are technologies used in additive manufacturing. But, some people think that these two are the same.

Using 3d Printing In Product Design And Development Deloitte Insights - Learn How 3D Printing Makes It Possible.

The First 3d Printer For Microfluidic Devices Allows One Step Prototyp Designnews Com. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. It shows the working phenomenon of 3d printer. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. 3d printing and rapid prototyping are technologies used in additive manufacturing. It works on the principle of streolithography. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry. It is also known as rapid prototyping. This kind of rapid prototype is particularly informative since the master model used. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. But, some people think that these two are the same. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Were explored by 3d printing several versions of electronic.

Pin On Additive Manufacturing 3 D Printers - Rapid Prototyping With 3D Printing Provides The Flexibility Required To Make This Crucial Trial And Error Process Possible For Physical Products.

Ultimate Beginner S Guide To 3d Prototyping Pick 3d Printer. Rapid prototyping with 3d printing provides the flexibility to create more realistic prototypes faster and implement changes instantly, elevating this crucial trial and error process. Subtractive manufacturing is a process in which 3d objects are constructed by cutting materials through a standard machining process such as drilling or milling. It works on the principle of streolithography. It shows the working phenomenon of 3d printer. Construction of the part or assembly is usually done using 3d printing or additive layer manufacturing technology. A wide range of 3d printing materials can produce tough functional prototypes for highly accurate performance testing, or realistic models that look and feel. Were explored by 3d printing several versions of electronic. But, some people think that these two are the same. This kind of rapid prototype is particularly informative since the master model used. Rapid prototyping allows engineers to thoroughly test prototypes that look and perform like final products, reducing the. It is also known as rapid prototyping. Rapid prototyping with 3d printing provides the flexibility required to make this crucial trial and error process possible for physical products. 3d files can be printed in plastic for discussion and testing with target groups, without spending money on precious metals. 3d printing and rapid prototyping are technologies used in additive manufacturing. Rapid prototyping transforms not only the design process but also the manufacturing of jewelry.