3D Printing Process Monitoring. The 3d printer is the next step in the process and our focus here. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Sift and ransac rescale and rectification, and. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Detection of defects during the printing process will help eliminate waste of material and time. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Defect detection during the initial stages of printing may generate an alert to either pause or stop the. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Cloud 3d printer management and infrastructure. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process.

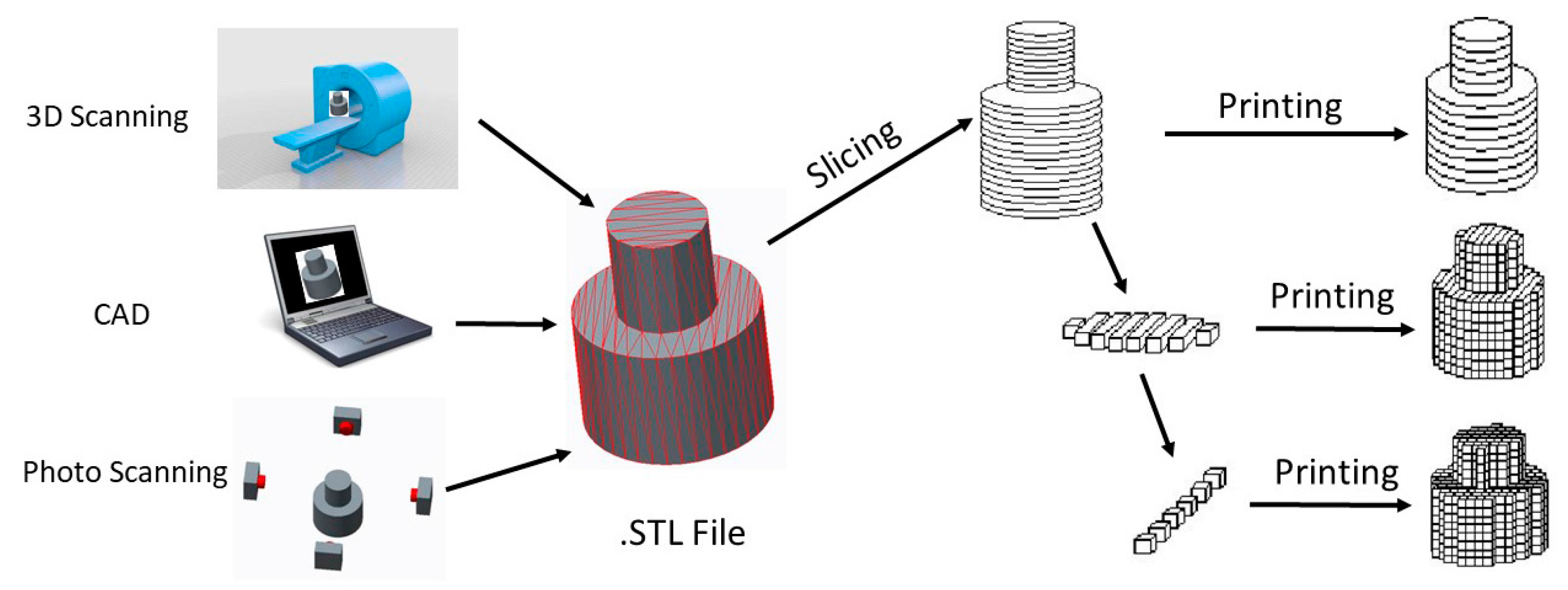

3D Printing Process Monitoring , 3D Printing Or Additive Manufacturing Is A Process Of Making Three Dimensional Solid Objects From A Digital File.

The Top 10 3d Printing Trends To Expect In 2020 Amfg. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Detection of defects during the printing process will help eliminate waste of material and time. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Sift and ransac rescale and rectification, and. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Cloud 3d printer management and infrastructure. The 3d printer is the next step in the process and our focus here. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos.

Complete printer management with prtg.

3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Learn how to 3d print. Many are able to record data. This tensile object was created using 3d injection printing, a new technology invented by umass lowell plastics engineering prof. This is a vital step as a 3d printer cannot conceptualize a 3d model in the. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). The observation of the temperature variation of a part that fails during construction provides insight into how the deposition process itself impacts temperature distribution within a single part leading to failure. The 3d printing industry continues to innovate its hardware as well as the materials and processes to create objects or parts. Stacked layers of material form the final 3d printed object. After each layer is complete, the print bed lowers on the. First, you need to choose which material will best achieve the specific properties required for your object. The 3d printing extrusion process source: The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Complete printer management with prtg. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The process for initiating these changes are detailed and the new slicer is used to help improve the function of the printer for er70s6 steel. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. Each of these layers can be seen as a thinly sliced. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The 3d printer is the next step in the process and our focus here. Every 3d printing process has its benefits and limitations and each is more suitable for certain applications than others. In an additive process an object is created by laying down successive layers of material until the object is created. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Cloud 3d printer management and infrastructure. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. When the previously printed number of pages is approaching the expected lifetime of the device, a replacement can be planned in a timely and controlled manner. The observation of the temperature variation of a part during construction provides insight into how the deposition process itself creates temperature distributions, which can lead to failure. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. A laser, monitored by the 3d printer software, then traces the pattern of the 3d design to form the final object layer by layer. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now!

Milan Polytechnic S Addme Lab Shows Off Progress In Process Monitoring Ai 3d Printing Media Network The Pulse Of The Am Industry . First, You Need To Choose Which Material Will Best Achieve The Specific Properties Required For Your Object.

Implementation Of Non Destructive Evaluation And Process Monitoring In Dlp Based Additive Manufacturing In Open Engineering Volume 7 Issue 1 2017. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. The 3d printer is the next step in the process and our focus here. Sift and ransac rescale and rectification, and. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Detection of defects during the printing process will help eliminate waste of material and time. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Cloud 3d printer management and infrastructure. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Defect detection during the initial stages of printing may generate an alert to either pause or stop the.

Lithoz Unveils New Ceravision Tool And Ceradoc Software For Remote Tracking And Monitoring Ceramic 3d Printing Process 3printr Com - The Second Step Is The Actual Printing Process.

Tech Offer In Process Monitoring Of Metal 3d Printing Complex Thermal Fluids Group. Detection of defects during the printing process will help eliminate waste of material and time. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. The 3d printer is the next step in the process and our focus here. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Cloud 3d printer management and infrastructure. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print).

Pdf Process Monitoring Of Extrusion Based 3d Printing Via Laser Scanning Semantic Scholar - 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Direct Metal Printing Odm 3d Systems. The 3d printer is the next step in the process and our focus here. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Cloud 3d printer management and infrastructure. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Sift and ransac rescale and rectification, and. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Detection of defects during the printing process will help eliminate waste of material and time. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means.

Authentise And Addiguru Combine To Enhance 3d Printing Process Monitoring Tct Magazine , The Sla 3D Printing Process First Appeared In The Early 1970S, When Japanese Researcher Dr.

Interview Admatec Launches Vision Based Process Monitoring System For Metal And Ceramic 3d Printing 3d Printing Industry. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. The 3d printer is the next step in the process and our focus here. Detection of defects during the printing process will help eliminate waste of material and time. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. Cloud 3d printer management and infrastructure. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Sift and ransac rescale and rectification, and. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Defect detection during the initial stages of printing may generate an alert to either pause or stop the.

Authentise Launches Tool To Simplify Tracking Of 3d Printing Powders 3d Prints , 3D Printing Or Additive Manufacturing Is A Process Of Making Three Dimensional Solid Objects From A Digital File.

Pdf Automated Process Monitoring In 3d Printing Using Supervised Machine Learning. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Cloud 3d printer management and infrastructure. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Sift and ransac rescale and rectification, and. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. The 3d printer is the next step in the process and our focus here. Detection of defects during the printing process will help eliminate waste of material and time.

Milan Polytechnic S Addme Lab Shows Off Progress In Process Monitoring Ai 3d Printing Media Network The Pulse Of The Am Industry . The Observation Of The Temperature Variation Of A Part During Construction Provides Insight Into How The Deposition Process Itself Creates Temperature Distributions, Which Can Lead To Failure.

Sensors Free Full Text The Boom In 3d Printed Sensor Technology Html. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Detection of defects during the printing process will help eliminate waste of material and time. The 3d printer is the next step in the process and our focus here. Cloud 3d printer management and infrastructure. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Sift and ransac rescale and rectification, and. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now!

Algorithm Of In Situ Process Monitoring Download Scientific Diagram . The 3D Printing Extrusion Process Source:

3d Printing Data Data Everywhere Cio Journal Wsj. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Detection of defects during the printing process will help eliminate waste of material and time. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Cloud 3d printer management and infrastructure. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Sift and ransac rescale and rectification, and. The 3d printer is the next step in the process and our focus here. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general.

Process Monitoring In 3d Printing Minifactory Oy Ltd . This Tensile Object Was Created Using 3D Injection Printing, A New Technology Invented By Umass Lowell Plastics Engineering Prof.

Pdf Process Monitoring Of Extrusion Based 3d Printing Via Laser Scanning Wim Abbeloos And Frederik Vogeler Academia Edu. The 3d printer is the next step in the process and our focus here. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Sift and ransac rescale and rectification, and. Cloud 3d printer management and infrastructure. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Detection of defects during the printing process will help eliminate waste of material and time. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now!

Imts 2018 Conference Process Monitoring And Control In Metal 3d Printing How To Tame The Tiger Today S Motor Vehicles , 3D Printing Is A Manufacturing Process That Creates A Three Dimensional Object By Incrementally Adding Material Until The Object Is Complete (This Contrasts With Subtractive Manufacturing Techniques Such As Carving Or Milling, In Which An Object Is Created By Selectively.

Additive Manufacturing Industry Trends And Outlook Formlabs. The 3d printer is the next step in the process and our focus here. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. Detection of defects during the printing process will help eliminate waste of material and time. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. Cloud 3d printer management and infrastructure. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Sift and ransac rescale and rectification, and. Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing.

Process Monitoring In 3d Printing Minifactory Oy Ltd - Defect Detection During The Initial Stages Of Printing May Generate An Alert To Either Pause Or Stop The.

The 12 Best 3d Printers 2020 For Professionals Hobbyists. The algorithm can determine what the flaw is and where it's happening, which can help increase process stability (the ability to print). Failures during the am process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build up components. The key to successful process monitoring is the intelligence of the system, said dr tobias abeln, technical director (cto) at eos. The 3d printer is the next step in the process and our focus here. Before assessing and correcting any imperfections, monitoring systems must be able to reduce the number of false alarms. Direct metal printing (dmp) gives you complete design freedom to manufacture stronger parts that are light, durable and perform better than other means. 3d printing software for monitoring quality assurance of additive manufacturing in real time get started with eos monitoring now! Defect detection during the initial stages of printing may generate an alert to either pause or stop the. Reducing process instability, and therefore the number of defective parts is one of the most important keys to reducing the costs of 3d printing in general. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Sift and ransac rescale and rectification, and. Detection of defects during the printing process will help eliminate waste of material and time. Cloud 3d printer management and infrastructure. Quality monitoring is still a big challenge in additive manufacturing, popularly known as 3d printing. Extrusion based 3d printing (e3dp) is an additive manufacturing (am) technique that extrudes thermoplastic polymer in order to build a solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process.