3D Printing Resin Molds. 3d printing molds takes an extra step. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. In this video, we go over the things you need to know to be successful. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. In this how to, we will show you some of the best practices associated. You can also create a product in a material that is not supported by your 3d printer. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. The low level of initial costs, repeatability, and design freedom were crucial factors for a. 3d printed injection molds in an aluminum frame with the finished injection molded part. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. We also compare 3d printed molds. First, you print a container that is the inversion of your final design; Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. Have you tried 3d printing a mold for casting yet?

3D Printing Resin Molds : How Are Resin Printers Constructed?

3d Printing Fishing Lure Molds Hackaday. In this how to, we will show you some of the best practices associated. 3d printed injection molds in an aluminum frame with the finished injection molded part. Have you tried 3d printing a mold for casting yet? 3d printing molds takes an extra step. We also compare 3d printed molds. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. In this video, we go over the things you need to know to be successful. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. First, you print a container that is the inversion of your final design; Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. You can also create a product in a material that is not supported by your 3d printer. The low level of initial costs, repeatability, and design freedom were crucial factors for a.

By fabian | february 19, 2020.

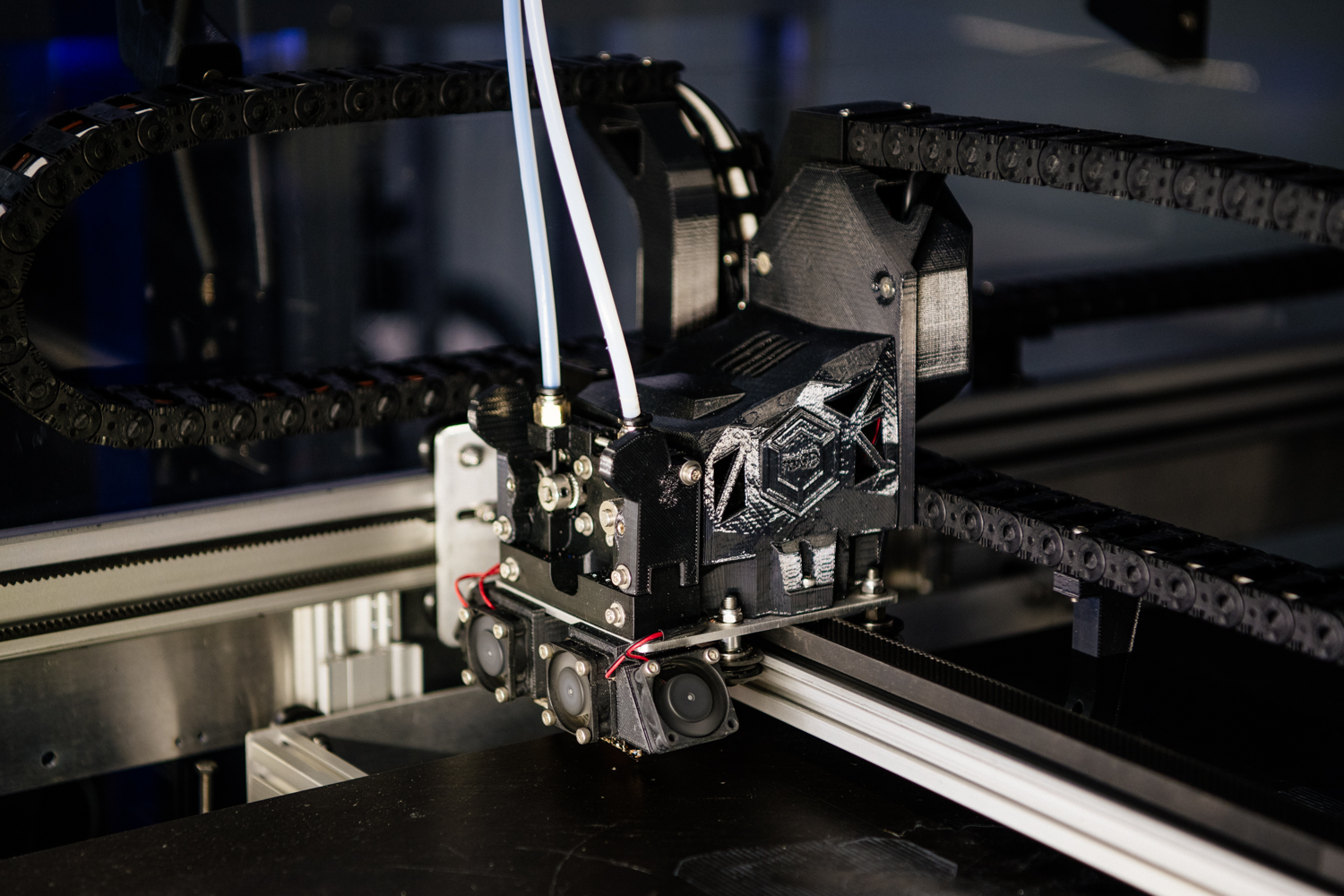

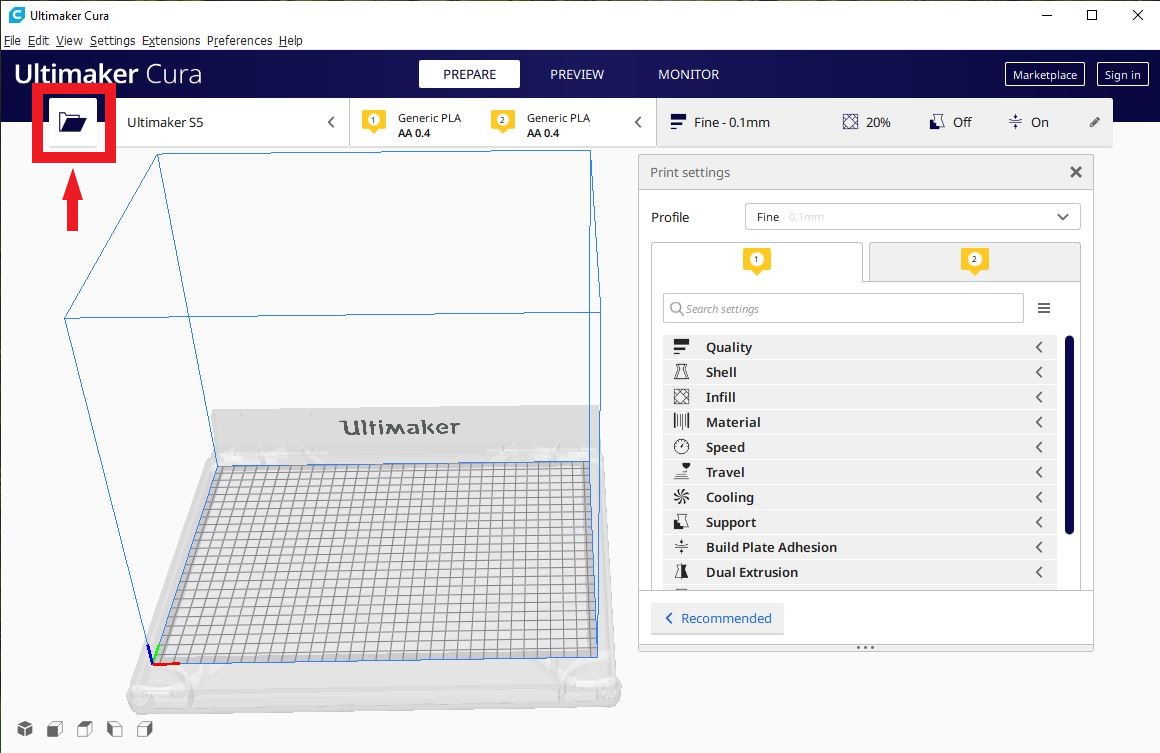

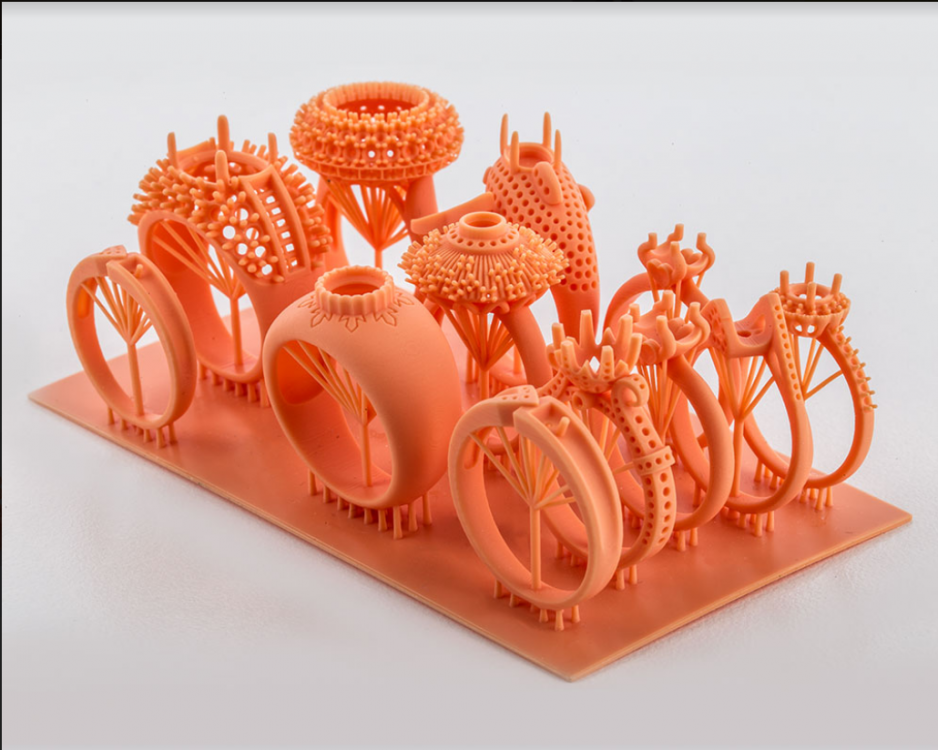

Hello solaleh, i have been encountering the same problem while trying to cure pdms in a 3d printed resin mold. Hello solaleh, i have been encountering the same problem while trying to cure pdms in a 3d printed resin mold. Combining rubber molding and 3d printing creates the opportunity that facilitates ergonomics testing and enables adding remarks and making instant changes in the model. Solsylva has an interesting diy rotational molding, or casting, machine used for hollow casting of resin or any other material that does not require heat. Metal fluid is a mix of metal grit in a resin binder that looks, feels, and weighs almost exactly the same as brass (in this project) or other metals. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. It also gives the designers the chance to control and modify the looks of the product at every phase of production, starting from the. High performance 3d printing services. How are resin printers constructed? First, you print a container that is the inversion of your final design; How resin 3d printing works: Suggestions and help are welcome and greatly appreciated. You can also create a product in a material that is not supported by your 3d printer. Have you found a solution that worked for you? With a shore d hardness values. Have you tried 3d printing a mold for casting yet? The middle piece goes in between the two walls 'floating' because its sides hold it in place. The low level of initial costs, repeatability, and design freedom were crucial factors for a. Feel free to ask questions, post cool. 3d printing molds takes an extra step. 3d printed injection molds in an aluminum frame with the finished injection molded part. You mentioned the printed resin is not softening which suggests it is not absorbing the sylgard via a dissolution type mechanism. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. Well, there may be a couple of extra. The only problem is you need a mold to cast the parts. In this video, we go over the things you need to know to be successful. That prototype is then glued much like sylatech, siemens uses 3d printers to print prototypes, which are eventually used to create molds for casting steel. The print is a mold itself, which reduces the time and costs. 3d printed pva molds are perfect for metal fluid casting because they don't deform once the material starts to give back heat. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can.

3d Printed Molds How To Get Started All3dp - In This How To, We Will Show You Some Of The Best Practices Associated.

Why Should You Use 3d Printed Molds. First, you print a container that is the inversion of your final design; Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. We also compare 3d printed molds. In this video, we go over the things you need to know to be successful. You can also create a product in a material that is not supported by your 3d printer. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. Have you tried 3d printing a mold for casting yet? A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. The low level of initial costs, repeatability, and design freedom were crucial factors for a. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. 3d printed injection molds in an aluminum frame with the finished injection molded part. In this how to, we will show you some of the best practices associated. 3d printing molds takes an extra step.

3d Printing Low Run Injection Molds 3d Hubs - Still, Printed Molds Have Their Place, And Some Shops Have Had Good Success With Them.

3d Printing Low Run Injection Molds 3d Hubs. In this video, we go over the things you need to know to be successful. 3d printing molds takes an extra step. The low level of initial costs, repeatability, and design freedom were crucial factors for a. We also compare 3d printed molds. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. First, you print a container that is the inversion of your final design; A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting.

Silicone Molds From 3d Prints For The Love Of Learning , Metal fluid is a mix of metal grit in a resin binder that looks, feels, and weighs almost exactly the same as brass (in this project) or other metals.

Therma Dm500 For 3d Printed Molds 3d Printing Media Network The Pulse Of The Am Industry. In this how to, we will show you some of the best practices associated. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. You can also create a product in a material that is not supported by your 3d printer. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. First, you print a container that is the inversion of your final design; 3d printed injection molds in an aluminum frame with the finished injection molded part. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. In this video, we go over the things you need to know to be successful. 3d printing molds takes an extra step. Have you tried 3d printing a mold for casting yet? We also compare 3d printed molds. The low level of initial costs, repeatability, and design freedom were crucial factors for a. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup.

3d Print Resin Mold Stlfinder , If Your Question Is About The 3D Modeling Aspect @Andrewsmodels Explanation From Years Ago Using Zbrush Is One Way.

Simple Reusable 3d Printed Mold In 2020 Pen Craft Prints 3d Printing. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. In this video, we go over the things you need to know to be successful. You can also create a product in a material that is not supported by your 3d printer. The low level of initial costs, repeatability, and design freedom were crucial factors for a. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. 3d printed injection molds in an aluminum frame with the finished injection molded part. In this how to, we will show you some of the best practices associated. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. We also compare 3d printed molds. 3d printing molds takes an extra step. First, you print a container that is the inversion of your final design; Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. Have you tried 3d printing a mold for casting yet?

Ultimate Guide To Silicone Molding For 3d Printing Part 1 Makerbot 3d Printers . I'm Thinking To Sell My 3D Characters Models And I'm Need More Informations About Process And Method.

Resin Casting With 3d Printed Molds Zmorph. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. In this how to, we will show you some of the best practices associated. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. You can also create a product in a material that is not supported by your 3d printer. In this video, we go over the things you need to know to be successful. The low level of initial costs, repeatability, and design freedom were crucial factors for a. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. Have you tried 3d printing a mold for casting yet? 3d printing molds takes an extra step. 3d printed injection molds in an aluminum frame with the finished injection molded part. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. We also compare 3d printed molds. First, you print a container that is the inversion of your final design; A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object.

Make Silicone Molds For Your 3d Printed Object 6 Steps With Pictures Instructables . Feel Free To Ask Questions, Post Cool.

Hey Guys I Finished Making The Mold For My 3d Print Poured Some Resin Copies And Finally Painted It Really Happy With How It Turned Out Printedminis. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. In this video, we go over the things you need to know to be successful. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. First, you print a container that is the inversion of your final design; You can also create a product in a material that is not supported by your 3d printer. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. The low level of initial costs, repeatability, and design freedom were crucial factors for a. 3d printed injection molds in an aluminum frame with the finished injection molded part. We also compare 3d printed molds. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. 3d printing molds takes an extra step. Have you tried 3d printing a mold for casting yet? In this how to, we will show you some of the best practices associated.

3d Printing Molds For Custom Joystick Balltop Spheres Cuddleburrito : That Prototype Is Then Glued Much Like Sylatech, Siemens Uses 3D Printers To Print Prototypes, Which Are Eventually Used To Create Molds For Casting Steel.

Resin Casting With 3d Printed Molds Zmorph. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. First, you print a container that is the inversion of your final design; With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. We also compare 3d printed molds. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. You can also create a product in a material that is not supported by your 3d printer. The low level of initial costs, repeatability, and design freedom were crucial factors for a. Have you tried 3d printing a mold for casting yet? In this video, we go over the things you need to know to be successful. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. 3d printing molds takes an extra step. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. 3d printed injection molds in an aluminum frame with the finished injection molded part. In this how to, we will show you some of the best practices associated.

Amazon Com Nova3d Wax Resin For Lcd 3d Printer 405nm 3d Printer Resin For Silicone Rubber Mold Press Print To Jewelry Design Dental Garage Kits 500ml Industrial Scientific , It Also Gives The Designers The Chance To Control And Modify The Looks Of The Product At Every Phase Of Production, Starting From The.

Casting Glass From 3d Printed Molds Amos Dudley. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. We also compare 3d printed molds. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. In this how to, we will show you some of the best practices associated. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. Have you tried 3d printing a mold for casting yet? In this video, we go over the things you need to know to be successful. 3d printing molds takes an extra step. 3d printed injection molds in an aluminum frame with the finished injection molded part. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. The low level of initial costs, repeatability, and design freedom were crucial factors for a. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. You can also create a product in a material that is not supported by your 3d printer. First, you print a container that is the inversion of your final design;

Learn How To Create A Two Part Silicone Mold From A 3d Print Matterhackers 3d Printing Diy 3d Printing Diy Silicone Molds : The Middle Piece Goes In Between The Two Walls 'fLoating' Because Its Sides Hold It In Place.

Casting Glass From 3d Printed Molds Amos Dudley. 3d printing molds takes an extra step. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. In this video, we go over the things you need to know to be successful. We also compare 3d printed molds. To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. 3d printed injection molds in an aluminum frame with the finished injection molded part. Have you tried 3d printing a mold for casting yet? The low level of initial costs, repeatability, and design freedom were crucial factors for a. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. In this how to, we will show you some of the best practices associated. First, you print a container that is the inversion of your final design; You can also create a product in a material that is not supported by your 3d printer.

Make Silicone Molds For Your 3d Printed Object 6 Steps With Pictures Instructables - A Typical Method For Casting Would Be The Following This Process Has Been Performed By Many And Is Used For Both Metal And Thermoset Plastic Resin Casting.

Tutorial 3d Printing Reusable Tpu Molds For Epoxy Resin 3d Printing. 3d printed injection molds in an aluminum frame with the finished injection molded part. The low level of initial costs, repeatability, and design freedom were crucial factors for a. Have you tried 3d printing a mold for casting yet? To determine how much resin you'll need, fill each of the molds with water and then pour the water from the molds into a measuring cup. Epoxy resin is a cheap and versatile material, so combining it with 3d printing opens the door to all sorts of jewelry, decor and figurines. In this how to, we will show you some of the best practices associated. 3d printing molds takes an extra step. You can also create a product in a material that is not supported by your 3d printer. A typical method for casting would be the following this process has been performed by many and is used for both metal and thermoset plastic resin casting. With affordable desktop 3d printers, temperature resistant 3d printing formlabs stereolithography (sla) 3d printers using high temperature resin can produce completely solid, smooth parts that can. Silicone molding is a powerful production method that, when combined with 3d printing, can allow you to make several copies of one product. We also compare 3d printed molds. Then you fill that container with your final manufacturing material, let that dry, then open the mold to reveal your final object. First, you print a container that is the inversion of your final design; In this video, we go over the things you need to know to be successful.