3D Printing Resin Process. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. The resin tank is filled with resin material either manually or automatically. The print is a mold itself, which reduces the time and costs of the process. Don't worry, we'll guide you. How does resin 3d printing work? Because of the fine details on parts printed with a resin printer, supports can be a bit more. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. With fdm, an unsupported overhang may. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Usually this energy is a light supports are still a requirement when printing with resin. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank.

3D Printing Resin Process - Because Photopolymers Are Photosensitive Under Ultraviolet Light, The Resin Is Solidified And Forms A Single Layer Of The Desired 3D Object.

How To Design Parts For Sla 3d Printing 3d Hubs. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. The print is a mold itself, which reduces the time and costs of the process. The resin tank is filled with resin material either manually or automatically. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Don't worry, we'll guide you. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. With fdm, an unsupported overhang may. Usually this energy is a light supports are still a requirement when printing with resin. Because of the fine details on parts printed with a resin printer, supports can be a bit more. How does resin 3d printing work? Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs.

Ameralabs 3d printer test part for resin 3d printers that will not only ease the stress of troubleshooting and calibration of your 3d printer but will this time we will introduce 3d printer test print called ameralabs town.

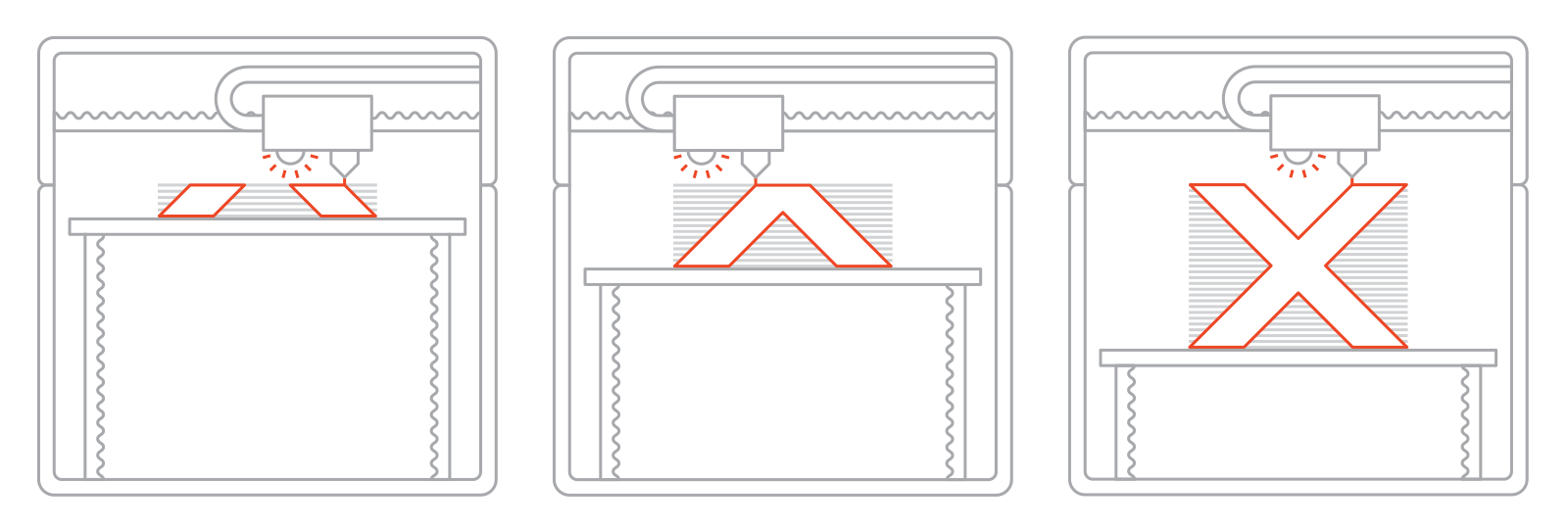

With so many resin printers dropping in price these days it's important to know what resins are a good price, and, more importantly, get the job done. Dimensional accuracies of common printing processes. It is designed explicitly to test materials for modelling, i.e. With fdm it's simply a case of popping the print off the built this is a continual learning process, so expect this to be added to and expanded on as i make horrible mistakes, and learn how to fix them in the process. You want it to print. This step removes the uncured layer from the print, helping to reduce any residual stickiness. Dlp printers use digital light processing dlp technology in designing and 3d printing objects. The print is a mold itself, which reduces the time and costs of the process. During solidification, the monomer carbon chains that compose the liquid in sla curing continues even after the completion of the printing process. Carl deckard at university of texas pioneers an alternative method of 3d printing, which turns loose powder into a solid, instead of chuck hall's liquid resin process. Best sla 3d printer resin. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Because of the fine details on parts printed with a resin printer, supports can be a bit more. Secondly, there are printers that solidify a photocurable resin. Most 3d printing processes are chosen to fulfill a specific purpose. The process of printing includes several steps. Transparent resin 3d printing service | i.materialise. Where resin printing differs from fdm printing the most is in the cleaning up process. Many 3d printing stores stock paper and mesh filters intended to capture large particles that might otherwise cloud your resin during the printing process. Also increasingly being used in traditional metal casting processes are 3d printed substitutes for 'lost wax' patterns. Resin 3d printers using the sla or dlp technologies are based on the photopolymerization process: Ameralabs 3d printer test part for resin 3d printers that will not only ease the stress of troubleshooting and calibration of your 3d printer but will this time we will introduce 3d printer test print called ameralabs town. The resin that is used in these printers is photosensitive and hardens up under uv light. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. The resin tank is filled with resin material either manually or automatically. When large, unsupported spans of material are printed, they are likely to warp underneath their own weight. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. With fdm, an unsupported overhang may. With so many resin printers dropping in price these days it's important to know what resins are a good price, and, more importantly, get the job done. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments.

Postprocess Develops Swift Solution For 3d Printed Sla Resin Removal 3d Printing Industry , The Creation Of A 3D Printed Object Is Oxygen Passes Through The Oxygen Permeable Window Creating A Thin Liquid Interface Of Uncured Resin Between The Window And The Printed Part.

Post Process Your Sla Prints In 4 Easy Steps Kudo3d. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. Don't worry, we'll guide you. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. The print is a mold itself, which reduces the time and costs of the process. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. With fdm, an unsupported overhang may. How does resin 3d printing work? Usually this energy is a light supports are still a requirement when printing with resin. Because of the fine details on parts printed with a resin printer, supports can be a bit more. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. The resin tank is filled with resin material either manually or automatically.

Sla Vs Dlp Guide To Resin 3d Printers Formlabs : The Process Of Printing Includes Several Steps.

Direct Light Processing For 3d Printers Uv Resin Dlp. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. With fdm, an unsupported overhang may. The resin tank is filled with resin material either manually or automatically. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. The print is a mold itself, which reduces the time and costs of the process. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Usually this energy is a light supports are still a requirement when printing with resin. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer.

Polymers Free Full Text Fabrication Of Conducting Polyacrylate Resin Solution With Polyaniline Nanofiber And Graphene For Conductive 3d Printing Application , The print is a mold itself, which reduces the time and costs of the process.

7 Steps To A Stronger Abs Part With Epoxy Penetrating Resin System. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. Don't worry, we'll guide you. Usually this energy is a light supports are still a requirement when printing with resin. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Because of the fine details on parts printed with a resin printer, supports can be a bit more. How does resin 3d printing work? Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. The print is a mold itself, which reduces the time and costs of the process. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. The resin tank is filled with resin material either manually or automatically. With fdm, an unsupported overhang may. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs.

Introduction To Sla 3d Printing 3d Hubs - Are You Working On A Project That Needs Intricate Best Dlp 3D Printer Resin.

Sla Post Processing Best Ways To Clean Resin 3d Prints All3dp. Don't worry, we'll guide you. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. With fdm, an unsupported overhang may. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The resin tank is filled with resin material either manually or automatically. How does resin 3d printing work? The print is a mold itself, which reduces the time and costs of the process. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. Usually this energy is a light supports are still a requirement when printing with resin. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. Because of the fine details on parts printed with a resin printer, supports can be a bit more. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers.

Which 3d Printed Resin Is Right For You 3d Printing Blog I Materialise - Compared To Fdm Printers, Resin Printing Will Seem As Though It Has Virtually No Tolerance For Overhangs.

Northwestern Researchers Develop Large Scale Sla Harp 3d Printer With Record Throughput 3d Printing Industry. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Because of the fine details on parts printed with a resin printer, supports can be a bit more. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. The print is a mold itself, which reduces the time and costs of the process. Usually this energy is a light supports are still a requirement when printing with resin. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Don't worry, we'll guide you. How does resin 3d printing work? A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. The resin tank is filled with resin material either manually or automatically. With fdm, an unsupported overhang may. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank.

The Two Dirty Secrets Of Resin 3d Printing Fabbaloo - Compared To Fdm Printers, Resin Printing Will Seem As Though It Has Virtually No Tolerance For Overhangs.

How To Design Parts For Sla 3d Printing 3d Hubs. Because of the fine details on parts printed with a resin printer, supports can be a bit more. How does resin 3d printing work? The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. The print is a mold itself, which reduces the time and costs of the process. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. Usually this energy is a light supports are still a requirement when printing with resin. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. With fdm, an unsupported overhang may. The resin tank is filled with resin material either manually or automatically. Don't worry, we'll guide you. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing - Once The Printing Process Is Completed And The Entire Object Has Been Printed, The Print Is Raised Out Of The Resin Tank.

Resin Vs Fdm 3d Printers Comparing Sla Dlp Lcd And Fdm Fff. Don't worry, we'll guide you. Because of the fine details on parts printed with a resin printer, supports can be a bit more. The print is a mold itself, which reduces the time and costs of the process. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. How does resin 3d printing work? Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. The resin tank is filled with resin material either manually or automatically. With fdm, an unsupported overhang may. Usually this energy is a light supports are still a requirement when printing with resin. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer.

Optimization And Characterization Of High Viscosity Zro2 Ceramic Nanocomposite Resins For Supportless Stereolithography Sciencedirect . The Resin Used For Sla Printing Takes Time To Harden Completely.

Types And Applications Of Resins For 3d Printers. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Usually this energy is a light supports are still a requirement when printing with resin. The print is a mold itself, which reduces the time and costs of the process. With fdm, an unsupported overhang may. Don't worry, we'll guide you. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. How does resin 3d printing work? Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. The resin tank is filled with resin material either manually or automatically. Because of the fine details on parts printed with a resin printer, supports can be a bit more. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments.

How Stereolithography Sla 3d Printing Works Manufactur3d : When Faced With Multiple Colors And Multiple Types, It's Easy To Get Turned Around When Trying To Choose The Right 3D Printing Resin.

3d Printing Models Hollow Vs Solid Sprintray Inc. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Don't worry, we'll guide you. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. With fdm, an unsupported overhang may. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Usually this energy is a light supports are still a requirement when printing with resin. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. How does resin 3d printing work? The resin tank is filled with resin material either manually or automatically. The print is a mold itself, which reduces the time and costs of the process. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. Because of the fine details on parts printed with a resin printer, supports can be a bit more.

New 3d Printing Process Replaces Layering With Faster Laser Resin Pro Designnews Com : Resins Used In 3D Printing Have Not Surprisingly, Resins' Toxicity Makes The Whole Process Of Disposal More Complex Than With Fdm And Plastic Filaments.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing. Resins used in 3d printing have not surprisingly, resins' toxicity makes the whole process of disposal more complex than with fdm and plastic filaments. Compared to fdm printers, resin printing will seem as though it has virtually no tolerance for overhangs. With fdm, an unsupported overhang may. Once the printing process is completed and the entire object has been printed, the print is raised out of the resin tank. The print is a mold itself, which reduces the time and costs of the process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or at last, 3d printed parts printed on supports require these structures to be removed, a manual process that is similar for both sla and dlp 3d printers. Resin printing involves curing a liquid resin by exposing it to an energy source which will trigger a hardening process. A variety of 3d printing resins from sprintray, manufacturer of the moonray 3d printer. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Usually this energy is a light supports are still a requirement when printing with resin. The resin tank is filled with resin material either manually or automatically. Because of the fine details on parts printed with a resin printer, supports can be a bit more. How does resin 3d printing work? Don't worry, we'll guide you.